Hand Crimp Tool 1.20mm (.047”) Pitch Pico-EZmate™ Crimp Terminals

Doc No: ATS-6381948000

Release Date: 08-17-09

UNCONTROLLED COPY

Page 2 of 6

Revision: A

Revision Date: 08-17-09

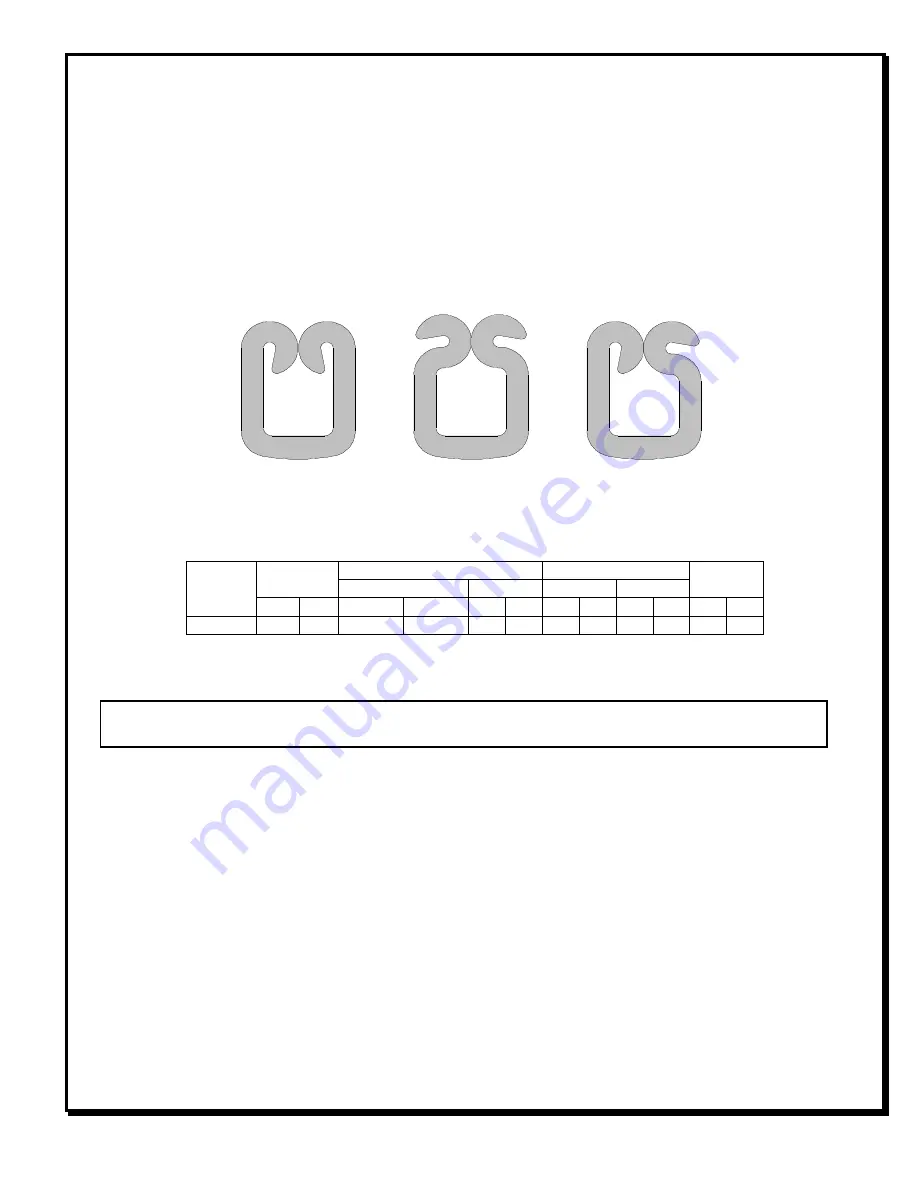

INSULATION CRIMP FORM

This crimp terminal is designed for miniaturization; therefore, each dimension of insulation crimp portion appears

small as compared to the terminal material thickness. In order to avoid insulation piercing the crimp forms by the

insulation barrel, coining is provided inside of the insulation barrel. For this reason, various crimp forms will occur at

the tip of the insulation crimp barrel shown in the figure below.

These crimp forms maybe changed completely by a small change in the wire, insulation punch, or terminal.

These crimp forms are satisfactory for original function of the insulation crimp portion and it is confirmed that all of

these forms below are acceptable insulation crimps.

CONDITIONS:

After crimping, the conductor profiles should measure the following.

Conductor Crimp (Ref)

Insulation Crimp (Ref)

Wire Size

Height

Width

Height

Width

Pull Force

Minimum

Terminal

Series No

AWG mm

2

mm

In.

mm

In.

mm

In.

mm

In.

N

Lb.

78172

28

0.08 0.44-0.48 .017-.019 0.85 .033 0.77 .030 0.85 .033 10.0 2.25

OPERATION

CAUTION:

Install only Molex terminals listed above with this tool. Do not crimp hardened objects as

damage can occur to the tool or die.

Open the tool by squeezing the handles together, at the end of the closing stroke, the ratchet mechanism will

release the handles, and the hand tool will spring open.

Crimping Terminals

1.

Select the desired terminal listed in the preceding charts.

2.

Cut a strip of the terminals approximately 5.0” off the reel. Position the terminal strip into the slot of the carrier

guide with terminals facing forward.

3.

Push the strip in until it locks into the (2) detent in the carrier guide and a terminal is centered with the punch

nest. See Figure 1.

4.

Partially close the jaws of the hand tool by squeezing the handles until you hear the fist click of the ratchet.

5.

From the top of the hand tool insert the pre-stripped wire into the terminal.

6.

Compress the terminal by squeezing the tool handles until the ratchet mechanism cycle has been completed.

Release handles to open the jaws.