Hand Crimp Tool 1.20mm (.047”) Pitch Pico-EZmate™ Crimp Terminals

Doc No: ATS-6381948000

Release Date: 08-17-09

UNCONTROLLED COPY

Page 4 of 6

Revision: A

Revision Date: 08-17-09

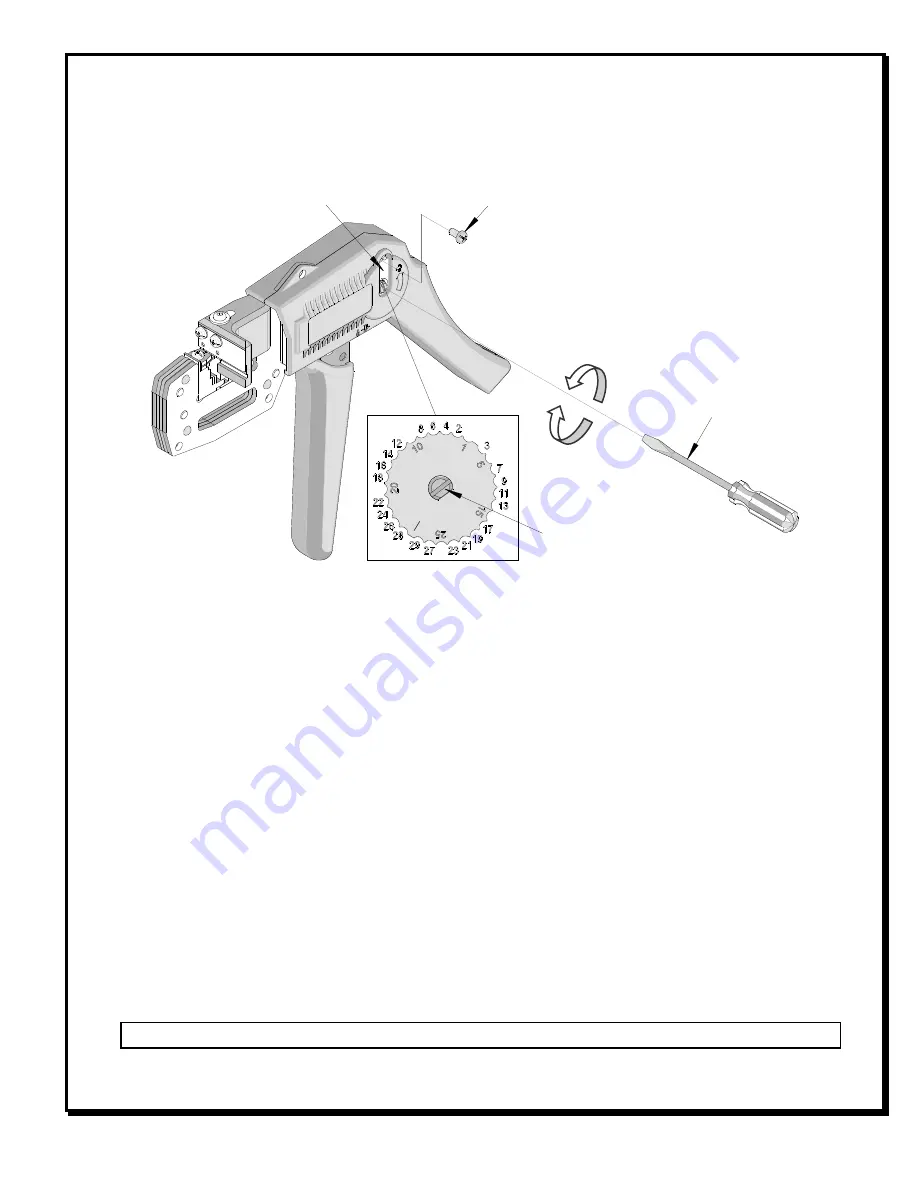

NUMBERED ADJUSTMENT

WHEEL

Figure 3

TURN CLOCKWISE (CW) OR

COUNTER CLOCKWISE (CCW)

TO ADJUST THE PRE-LOAD

TURN WITH A SMALL

SCREW DRIVER

REMOVE THE LOCKING 2MM SCREW

How to Adjust Tool Preload

It may be necessary over the life of the tool to adjust tool handle preload force. Listed below are the steps

required to adjust the crimping force of the hand tool to obtain proper crimp conditions:

1.

Remove the 2mm locking screw from the numbered adjusting wheel using a screw driver. See Figure 3.

2.

Using the same screw driver turn the adjustment wheel to the next highest number.

Note: The uneven numbers are in clockwise (CW) direction and the even numbers are counter clockwise

(CCW).

3.

Example: If the preload is set at number 5, then to increase the preload, turn the adjustment wheel until the 6

th

position is located over the 2mm locking screw tapped hole. If it is necessary to move to the 7

th

position, then

the adjustment wheel should be turned counter clockwise (CCW) until the 7

th

position is over the 2mm locking

screw tapped hole.

4.

Replace the 2mm locking screw, aligning the nearest notch in the setting wheel to locking screw.

5.

Check the crimp specifications and conduct a pull test after tool handle preload force is adjusted. Repeat

these steps until the desired result is obtained.

Warranty

This tool is for electrical terminal crimping purposes only. This tool is made of the best quality materials. All vital

components are long life tested. All tools are warranted to be free of manufacturing defects for a period of 30

days. Should such a defect occur, we will repair or exchange the tool free of charge. This repair or exchange will

not be applicable to altered, misused, or damaged tools. This tool is designed for hand use only. Any clamping,

fixturing, or use of handle extensions voids this warranty.

CAUTION

: Molex crimp specifications are valid only when used with Molex terminals and tooling.