AT-200 Air-Powered Crimp Tool

Doc No: TM-192790001

Release Date: 07-01-02

UNCONTROLLED COPY

Page 11 of 20

Revision: G

Revision Date: 01-17-14

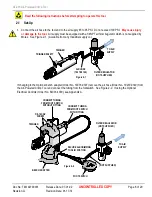

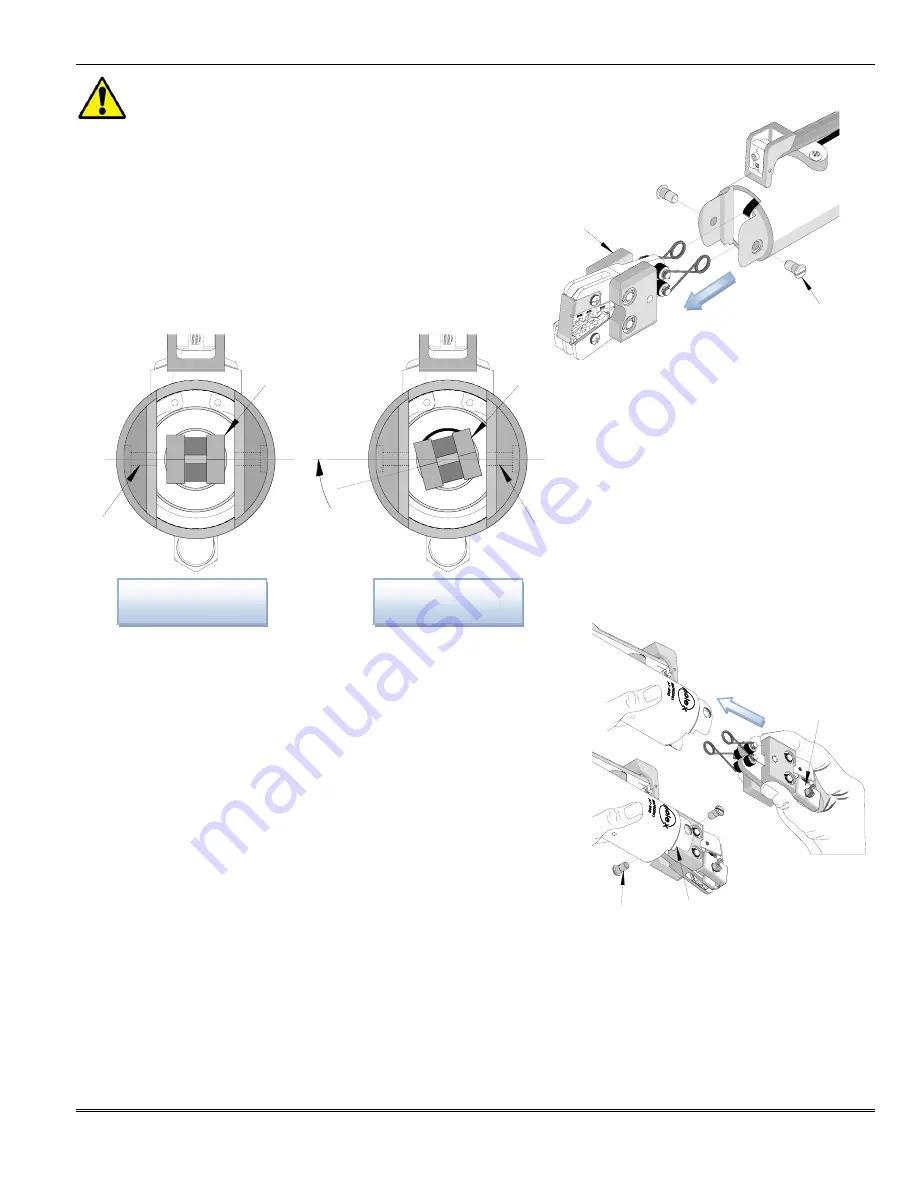

TURN

CLOCKWISE

(CW)

CAM

INCORRECT CAM

ALIGNMENT

#1/4-20

HOLE

CORRECT CAM

ALIGNMENT

Figure 3-2

CAM

#1/4-20

HOLE

CAUTION

: Always disconnect air supply before all maintenance.

3.1 Changing Crimp Tool Heads

1.

Disconnect the air supply.

2.

Remove the (2) #1 /4-20 slotted screws on both sides of

the power unit. Pull the crimp tool head jaw assembly

out of the tool. See Figure 3-1.

3.

Before attempting to replace the dies, make sure the

wedge points of the cam line up with the (2) #1/4-20

holes in the front of power unit. See Figure 3-2.

If the cam is not lined up, use the following procedure.

a)

Disconnect the air supply with the cam in the retracted

position trigger is up.

b)

Grasp the center section of the cam with a long nose plier

and rotate the cam clockwise (CW) until the center line of the

wedge line up with (2) #1/4-20 holes in power unit. See

Figure 3-2 for the correct alignment.

c)

Replace the head before cycling the tool. Be sure both

screws are in place and tightened.

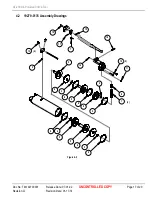

4.

To replace the crimp tool head, hold power unit in left hand as

shown in Figure 3-3.

5.

Grasp the crimp tool head with the right hand and with the

terminal locator facing you. Slide the crimp tool head assembly

into the body of the power unit until the side plates of the crimp

tool head butt against the steps in the power unit. Be sure the

jaw return springs clear the cam in the power unit. See Figure 3-3.

6.

Line up the holes in the crimp tool head with the holes in the housing of the power unit.

7.

Replace the (2) #1/4-20 screws and tighten securely. The tool is now ready for use.

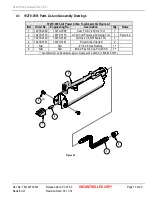

CRIMPIMG HEAD

JAW ASSY

#1/4-20 SLOTTED

SCREWS (2)

Figure 3-1

CRIMPING HEAD

BUTTS UP

AGAINST STEPS

#1/ 4-20

SCREWS (2)

TERMINAL

LOCATOR

SLIDE IN

POWER UNIT

Figure 3-3