AT-2212 Air Crimp Tool Head

Doc No: ATS-640053600

Release Date: 06-24-03

UNCONTROLLED COPY

Page 4 of 8

Revision: B

Revision Date: 09-30-05

4.

Remove the crimped connector and inspect for proper crimp location and insulation closure. It may be required

to rotate crimped connector 90

°

to remove from the tool. Molex offers a Crimp Inspection Handbook for closed

barrel industrial product. See our website or contact your sales engineer.

Maintenance

It is recommended that each operator of the tool be made aware of, and responsible for, the following

maintenance steps:

1.

Remove dust, moisture and other contaminants with a clean

brush, or soft, lint-free cloth.

2.

Do not use any abrasive materials that could damage the tool.

3.

Make certain all pins; pivot points and bearing surfaces are

protected with a thin coat of high quality machine oil. Do not oil

excessively. This tool was engineered for durability, but like any

fine piece of equipment it needs cleaning and lubrication for a

maximum service life of trouble-free crimping. Use a light oil

such as 30 weight automotive oil at the oil points shown in

Figure 4, every 5,000 crimps or monthly will significantly

enhance the tool life and ensure a stable calibration.

4.

When tool is not in use store the tool in a clean, dry area.

CAUTION:

This crimp tool requires a regulated air supply line with operating pressure of 60 to 70 PSI. Higher

pressure may cause damage to the tool.

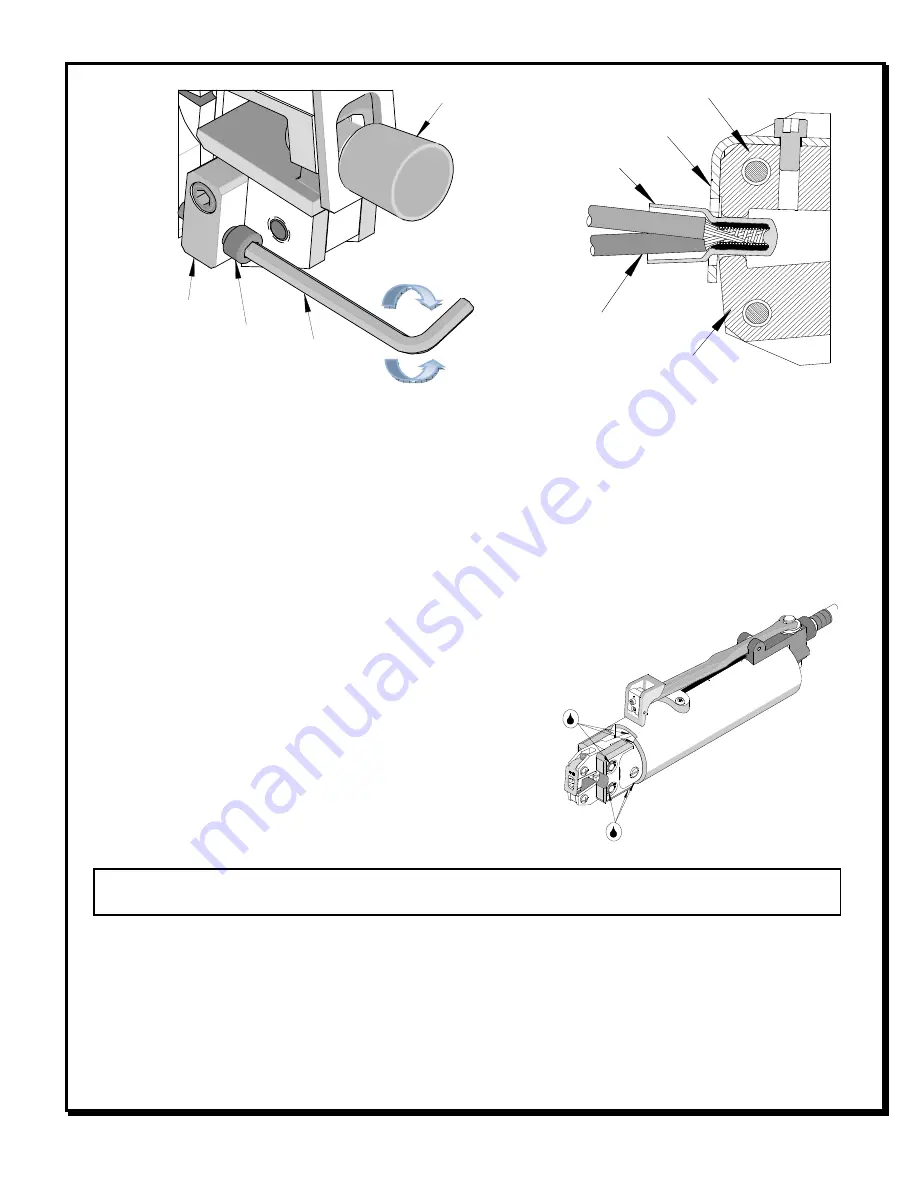

LUBRICATION POINTS

(BOTH SIDES) LIGHT OIL

(EVERY MONTH OR

5,000 CRIMPS)

Figure 4

ADJUSTMENT

BLOCK

CONNECTOR

Figure 2

3/32” ALLEN

WRENCH

ADJUSTING

SCREW

CLOSE

JAWS

OPEN

JAWS

Figure 3

LOCATOR

PRE-TWISTED

WIRE

CONDUCTOR PUNCH

CONDUCTOR

ANVIL

CONNECTOR