CS 150 Battery Crimping Tool

Doc No: ATS-638160200

Release Date: 12-06-07

UNCONTROLLED COPY

Page 9 of 21

Revision: A

Revision Date: 12-06-07

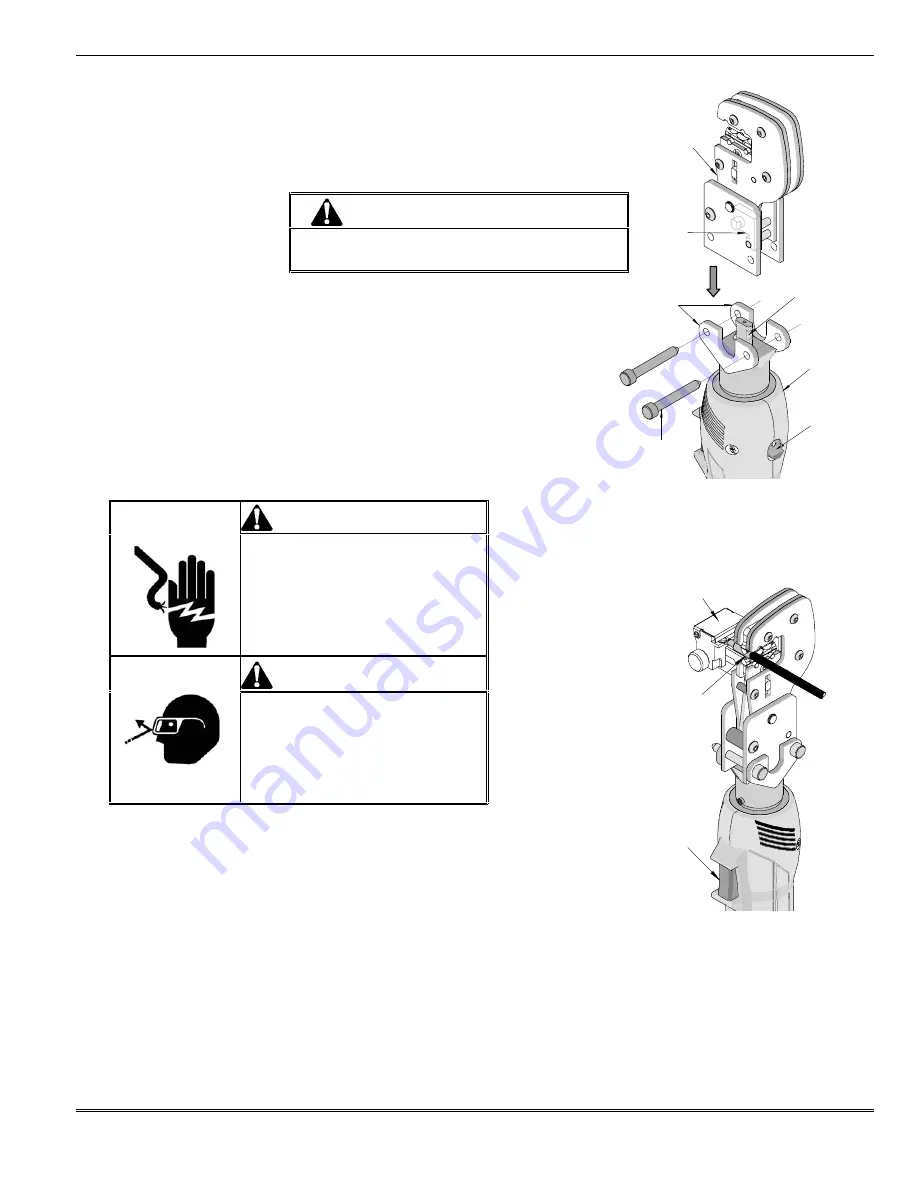

3.1 Set-Up

Before starting any work on electrical applications make sure there are no

live cables or parts in the immediate area of the user.

WARNING

Remove the battery from the crimping tool before

installing and removing dies in the crimp head.

1. Select the appropriate crimping head with the proper tooling kit

inserted for the application needed.

2. Remove the locking pins (2) from the adapter plate on the crimping

tool.

3. Place the crimping head into the adapter and push down until it

engages into the slot of the adapter.

4. Replace the locking pins (2) making sure the crimping head is secure.

The locking pins can be inserted from either side of the adapter plate.

See Figure 3-1.

WARNING

Electric shock hazard:

This tool is not insulated. When using this

unit near energized electrical lines, use

proper personal protective equipment.

Failure to observe this warning could

Result in severe injury or death.

WARNING

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection could

result in serious eye injury from flying

debris or hydraulic oil.

3.2 Operation

1. Insert the proper terminal or connector into the tooling nest and push on the

trigger in the handle just enough so the dies contact the terminal or connector

securely. Release the trigger. This allows the operator to make adjustments

to the connector before the final termination.

2. Insert the wire or cable into the terminal. Push on the wire or cable to assure it is fully seated in the

terminal.

3. Hold the trigger down again until the crimping tool achieves pressure relief, which is accompanied by an

audible “pop”.

Figure 3-2

WITH LOCATOR

HOLD

TRIGGER

DOWN

TERMINAL

AND WIRE

IN PLACE

Figure 3-1

LOCKING

PINS (2)

CRIMPING

TOOL

CRIMPING

HEAD

ADAPTER

CRIMPING

HEAD WITH

TOOLING

ADAPTER

PLATES

LOCKING

LATCH

RETRACT

SLIDE