PRODUCT APPLICATION SPECIFICATION

THIS DOCUMENT CONTAINS INFORMATION THAT IS PROPRIETARY TO MOLEX ELECTRONIC TECHNOLOGIES, LLC AND SHOULD NOT BE USED WITHOUT WRITTEN PERMISSION

REVISION

DESCRIPTION

REVISED

APPLICATION SPECIFICATION FOR

MICRO-LOCK PLUS 2.0 SINGLE ROW

CHANGE NO.

682239

REVISED BY

SOKUMURA01

DATE

2021/02/09

DOC TYPE

DOC TYPE DESCRIPTION

DOC PART

SERIES

REV APPR BY AIDA

DATE

2022/06/30

PS

APPLICATION SPECIFICATION WORD

A03

505570

INITIAL RELEASE

CUSTOMER

DOCUMENT NUMBER

REVISION

SHEET

INITIAL DRWN KUSATO

DATE

2016/04/20

GENERAL MARKET

5055700001

E

19

OF

49

INITIAL APPR

TKANEKO

DATE

2016/04/21

PROCEDURE: 2090580010-ES TEMPLATE: 2090580010-PAS-A4 REVISION: A1

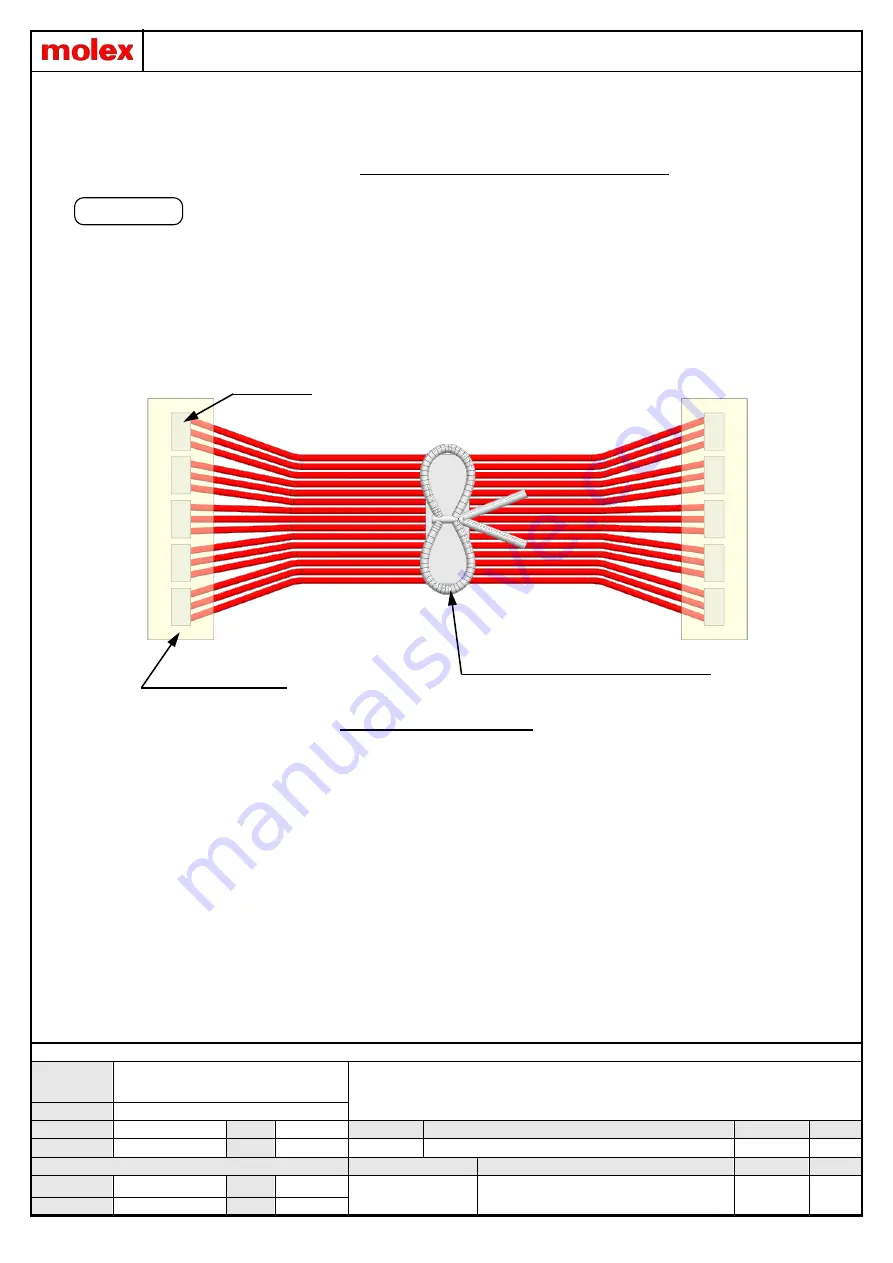

band at the center with vinyl string

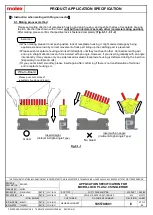

Fig.8-1 A bunch of harness

【

8. Recommended packaging of cable harness and assemblies

】

When packing harness after processing, procedure and instruction (

※

) are shown below.

1.

Bundle the harness after processing. Please band 20 harness at most in one bunch.

※

When bundle the harness, in order to avoid applying excessive force constantly, please do not use anything

that fastens tightly such as rubber band. Please band at the center (at one point) with vinyl string. Please take

measure to protect connector from shock or load by wrapping each bunch of connector with air packing.

(Fig.8-1)

When some harness is banded, each connector contact and part of lock might be loaded. In that case,

deformation of lock part etc. might cause defective performance because the lock being down all the time.

Also, it may cause damage to the movable parts (mold lances and lock parts), which might cause

defective performance.

Air packing

Instruction

Connector