RHT-4754 Hand Crimp Tool

Doc No. 64003-7200

Release Date: 08-02-06

UNCONTROLLED

COPY

Page 2 of 7

Revision: A

Revision Date: 08-02-06

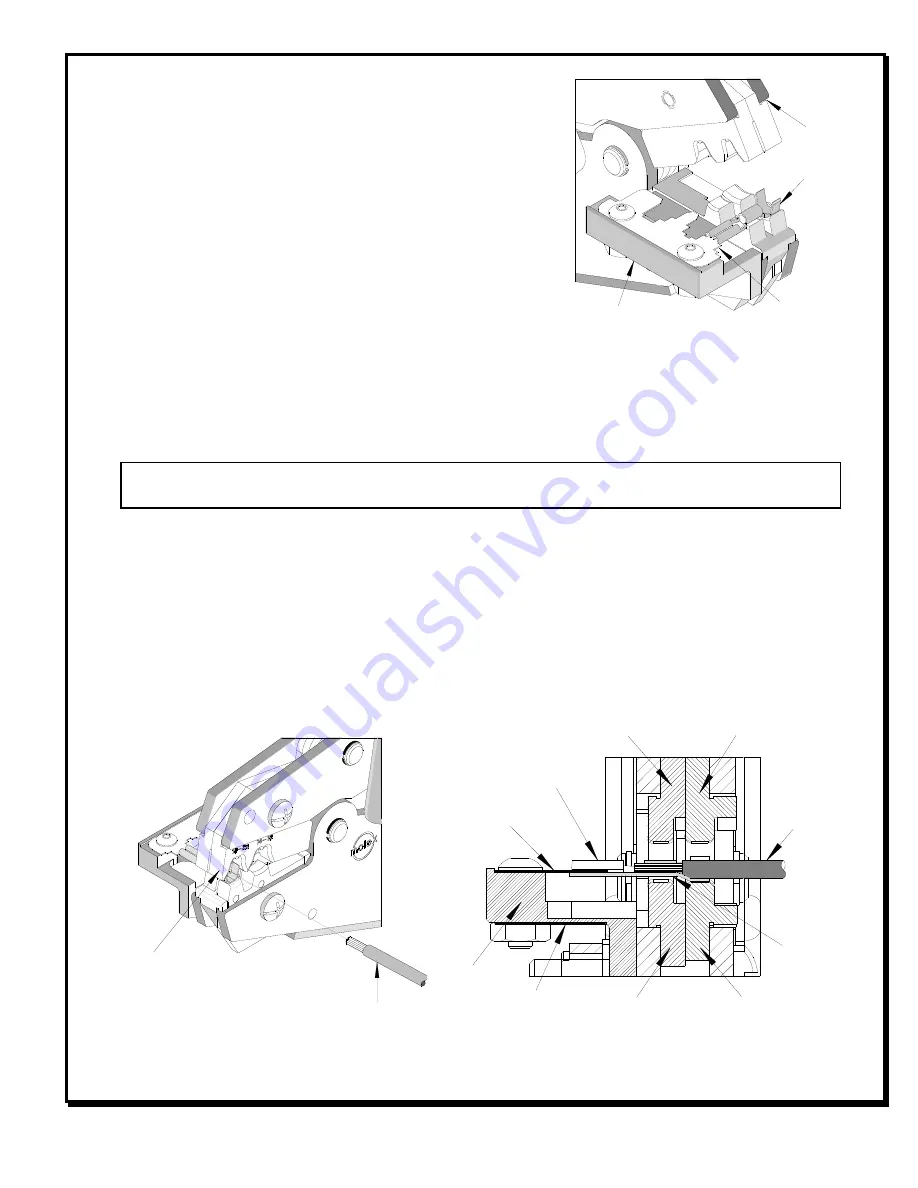

Figure 3

2

ND

TAB

LOCATOR

WIRE

TERMINA

L

BARREL

INSULATIO

N

PUNCH

CONDUCTOR

ANVIL

TERMINA

L

LOCATO

R

CONDUCTO

R

PUNCH

INSULATION

ANVIL

1

ST

TAB

LOCATOR

Figure 2

TERMINAL

WIRE

OPERATION

Open the tool by first closing the jaws sufficiently for the

ratchet mechanism to release.

Crimping Terminals

1. There are 2 Tab Locator Blades supplied with the

tool. One is for .187 and .250 Tabs; the other is for

.205 Tabs and .110 Tabs. Make sure the proper

blade is installed on the top of the locator and the

other is stored on the bottom of the locator.

2. Push the terminal onto the tab locator all the way to

the stop in the nest. The barrel of the terminal should be up. See Figure 1.

3. Partially close the tool to hold the terminal in place. See Figure 2.

4. Insert the properly stripped wire into the terminal barrel. See Figure 2 and 3. Cycle the

tool.

Note:

The tamper proof ratchet action will not release the tool until it has been fully

closed.

5. Remove the crimp and inspect for proper crimp location, and check for insulation closure.

Molex offers a Crimp Inspection Handbook for closed barrel industrial product. See our

website or contact your sales engineer.

6. If the insulation part of the crimp needs to be adjusted, first loosen the M4 screw on the

bottom tool jaw, then insert a 3/32 hex wrench (supplied) into the bottom of the lower die.

See Figure 4. A clockwise (CW) rotation decreases insulation crimp while a counter-

clockwise (CCW) rotation increases insulation crimp. After adjusting retighten the M4

screw.

LOCATOR

JAWS

OPEN

TAB

LOCATOR

Figure 1

TERMINA

L