RHT-4754 Hand Crimp Tool

Doc No. 64003-7200

Release Date: 08-02-06

UNCONTROLLED

COPY

Page 5 of 7

Revision: A

Revision Date: 08-02-06

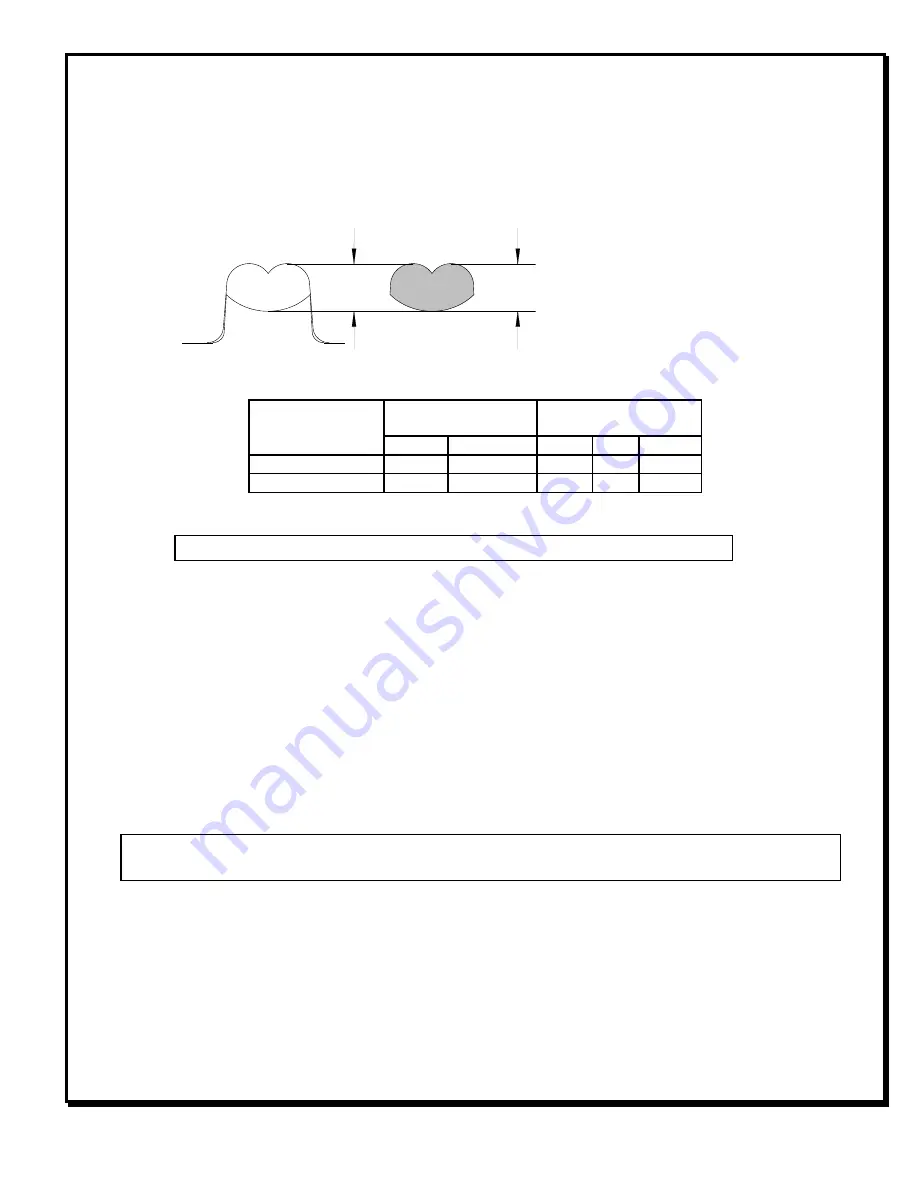

“ X ”

NOT POSSIBLE TO PIN GAUGE,

MEASURE A

CRIMPED UNINSULATED TERMINAL OR

SLUG*

*SOLDER, LEAD OR

SIMILAR SOFT

METAL

Tool Calibration

A Certificate of Calibration (See Last Page) was supplied with the tool. To recalibrate this

Tool, a soft metal slug or solder should be crimped in the conductor nest and the “

X

”

Dimension measured in each conductor nest and compared to this chart. The tool should be

lubricated prior to recalibration to ensure consistent measurements. Handle preload is

factory set to 25-45 LBS. See How to Adjust Tool Preload (See Figure 7) to recalibrate.

Nest Color Code

Wire Range

“X” Dimension

Conductor Crimp

Awg

mm²

Mean

Go

No Go

Red

22 - 18 0.35 - 0.80

.052

.049

.060

Blue

16 - 14 1.30 - 2.00

.061

.058

.069

CAUTION:

Repetitive use of this tool should be avoided.

Warranty

This tool is for electrical terminal crimping purposes only. This tool is made of the best quality

materials. All vital components are long-life tested. All tools are warranted to be free of

manufacturing defects for a period of 30 days. Should such a defect occur, we will repair or

exchange the tool free of charge. This repair or exchange will not be applicable to altered,

misused or damaged tools. This tool is designed for hand use only. Any clamping, fixturing,

or use of handle extensions voids this warranty.

Hand held crimping tools are intended for low volume, prototyping, or repair requirements

only.

CAUTION

: Molex crimp specifications are valid only when used with Molex terminals,

applicators and tooling.