RHT-4754 Hand Crimp Tool

Doc No. 64003-7200

Release Date: 08-02-06

UNCONTROLLED

COPY

Page 6 of 7

Revision: A

Revision Date: 08-02-06

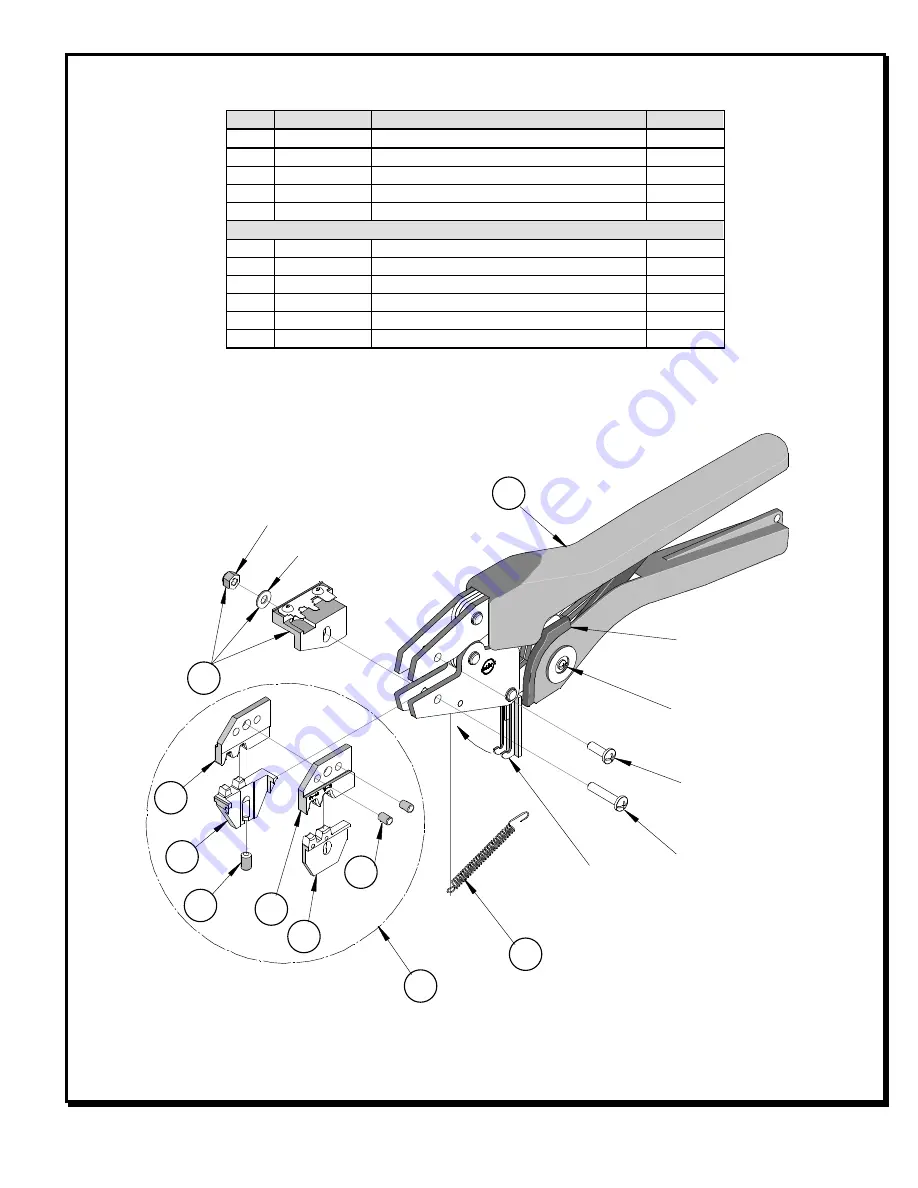

Figure 6

M4 X 25 LG

PAN HEAD

SCREW

FOR SPRING

ACCESS

SWING

OPEN COVER

6

SCREW AND

PLASTIC

COVER FOR

HANDTOOL

PRELOAD

ADJUSTMENT

RATCHET

RELEASE

LEVER

3

1

2

M4 X 12LG

PAN HEAD

SCREW

M4 LOCKNUT W/

HEX NYLON

INSERT

M4 FLAT

WASHER

10

7

8

9

5

4

REPAIR KIT. ALL PARTS

REQUIRED FOR

REPAIR. (ONLY MAIN SPRING

SHOWN)

(2)

PARTS LIST

Item

Order No

Description

Quantity

64003-7200

Hand Crimp Tool

(Fig. 6)

1

64000-0076

Repair Kit (Springs, Pins and E-Rings)

1

2

63810-0000

Handle

1

3

64003-1175

Locator Assembly

1

4

64003-7270

Tooling Kit

1

Tooling Kit Only

5

64003-7202

Conductor Punch

1

6

64003-7201

Conductor Anvil

1

7

64003-7204

Insulation Punch

1

8

64003-7203

Insulation Anvil

1

9

N/A

4 mm Dia. by 5.0 mm Lg.Roll Pins

2**

10

N/A

#10-

32 by 5/16” Lg. Cup Pt. Set Screw

1**

** The following purchased parts are available from an Industrial supply company such as MSC

(1-800-645-7270).