Section 7 — lp-GaS SyStemS

10

camelot 2007

TIP

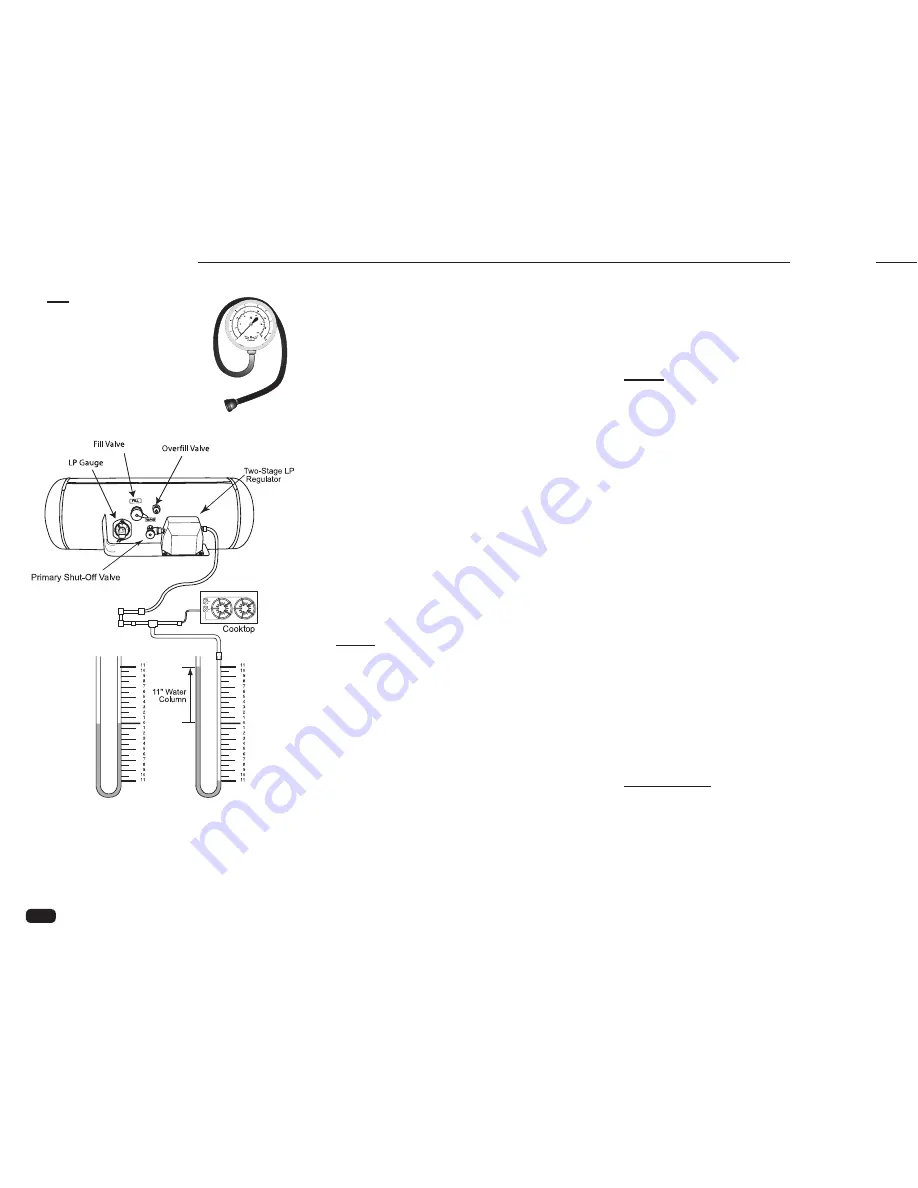

Attach the manometer

gauge to the accessory

hookup line to avoid

loosening any interior

LP-Gas line connections.

lp-gaS HoSe InSpectIon

It is suggested by the hose manufacturer that

a flexible LP-Gas supply hose undergo regular

inspection. As a guideline, it is recommended

that all flexible LP-Gas lines connecting the

slide-out, appliances and tanks be inspected in

the spring and fall of each year by a qualified RV

technician.

Inspection tips:

Hose strength is controlled by the plies of

reinforcement. Damage in this area cannot

be tolerated. It is important that if a damaged

LP-Gas hose is found, the source of the damage

be determined and corrected prior to the

replacement. Small cuts, nicks, or gouges that

do not go completely through the cover are not

cause for replacement of the hose. Inspection

should be performed when the hose is not under

pressure.

NOTE

Pricking of the cover in the manufacture

of this type of hose is common and

necessary for satisfactory hose

performance. Consequently, the

uniformly pricked cover should not be

viewed with alarm.

Cause for hose replacement:

Damage to the textile reinforcement or

wire braid; wire braid reinforced hose,

which has been kinked or flattened so as

to permanently deform the wire braid in

the un-pressurized state.

Blistering or loose outer cover.

Slippage; evidenced by the misalignment

of the hose and coupling and/or the

scored or exposed area where slippage

has occurred.

NOTE

Only a qualified RV service technician

should complete replacement of LP-Gas

components.

Additional suggested maintenance:

After performing extensive testing the

manufacturer of the flexible LP-Gas supply

hoses has determined that the hoses be

replaced every ten (10) years as the failure

rate may increase after this period of time.

The motorhome manufacturer recommends

following this guideline to assure continued

safety and dependable use.

lp-gaS DIStrIButIon lIneS

A primary manifold black steel pipe running

throughout the motorhome distributes LP-Gas

to secondary lines. All secondary lines leading

to gas appliances are made of copper tubing

with flared fittings. It is recommended that gas

distribution work be performed by an authorized

dealer or an authorized service technician.

INSPECTION

Inspect the rubber flexible lines twice a

year for abrasions, tears, kinks or other

signs of damage.

If a gas leak is suspected, have the system

inspected and repaired by a qualified service

technician as soon as possible.

050259h

050260

U-Tube Testing Layout

Summary of Contents for Camelot 2007

Page 16: ......

Page 18: ......

Page 49: ...45 Section 2 Driving Safety Camelot 2007 Weight Record Sheet Actual Worksheet 020255b...

Page 53: ...49 Section 2 Driving Safety Camelot 2007 Weighing Procedure Worksheet 020255c...

Page 106: ...appliances 4 102 Camelot 2007 Notes...

Page 140: ...Section 5 Equipment 136 camelot 2007 Notes...

Page 155: ...151 Section 6 water systems camelot 2007 Water service center Typical Water System...

Page 156: ...Section 6 water systems 152 camelot 2007 Notes...

Page 186: ...Section 8 Electrical Systems House 182 camelot 2007 Notes...

Page 202: ...Section 9 Electrical Systems Chassis 198 camelot 2007 engine no start flow chart...

Page 244: ...Section 10 chassis information 240 camelot 2007 42 Tag Axle Models 070171i 070171j...

Page 258: ......