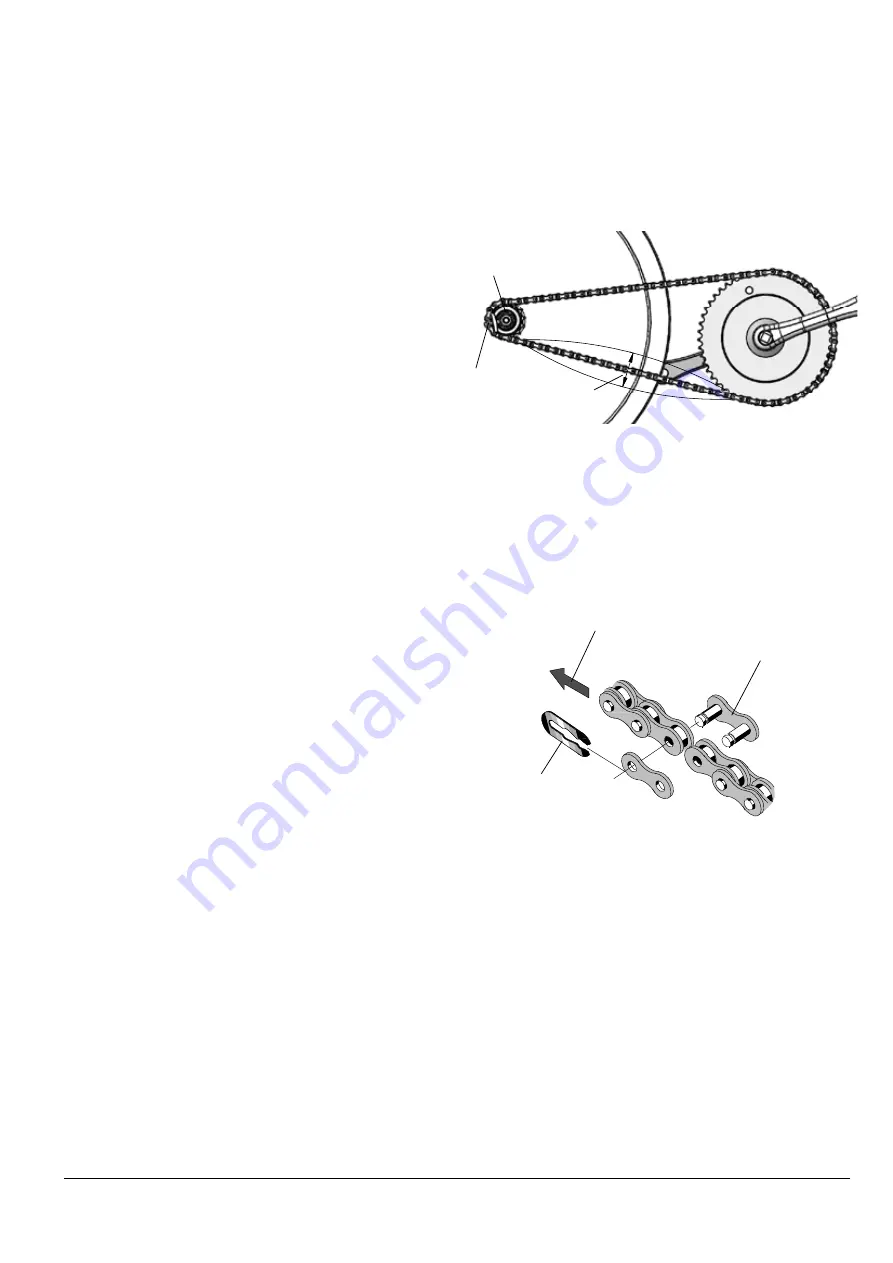

Chain 1/2“ x 1/8“

It is strongly recommended to keep the chain clean.

Dirt build-up on the chain will cause excess wear. A

chain lubricant and solvent for normal road bikes

may be used.

Check the lubrication and tension of the chain at

regular intervals. In the middle of its free length the

chain should have a minimum play(3) of 10 mm (1/4

inch). See fig: Chain adjustments. When the play in the

chain is about 20 mm (3/4 inch) it must be tightened

otherwise it will cause abnormal wear of the chain and

chainwheels. Because of this it is always recommended

to keep the chain play as little as possible. Loosen the

hub nut(2) on both sides and tense the chain with the

chain adjuster(1) when needed.

When the chain has become so long that it can no

longer be tightened with the chain adjusters it is worn

out and should be replaced with a new one.

To adjust or replace the chain remove frame covers if

necessary.

To adjust the chain the hub nuts(2) should be

loosened. Loosening or tightening the nuts on the

chain adjusters(1) will then move the hub and axle

forward or backward. Adjust according to above

recommendation. Then tighten the nuts on the hub

axle again. See fig: Chain adjustments.

To replace the chain, loosen the chain adjuster as much

as possible. Dismantle the chain lock(6) and remove

the chain. Put on a new chain and assemble the chain

lock. The spring of the chain lock should be assembled

with the closed end in the movement direction(5) of

the chain. Use a pair of tongs for dismantling and

assembling the spring(4). See fig: Chain replacement.

NOTE: At assembly, the flywheel has to be parallel

with the centerline of the frame otherwise the chain

and chain wheels make a lot of noise and wear out

rapidly.

Adjust chain adjusters to allow chain play according

to above. Tighten hub nuts firmly. Replace frame

covers.

Fig: Chain adjustments

1) Chain adjuster

2) Hub nut

3) Chain play

Fig: Chain replacement

4) Lock spring

5) Movement direction

6) Chain lock

3

2

1

4

6

5

Monark 928 E Pro VO

2

14

Summary of Contents for 928 E Pro VO2

Page 1: ...Manual 928 E Pro VO2...

Page 2: ......

Page 18: ...Monark 928 E Pro VO2 18 Notes...

Page 19: ...Monark 928 E Pro VO2 19 Notes...