38

AS 914 TI

User Manual

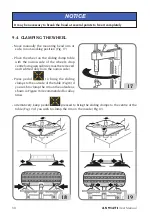

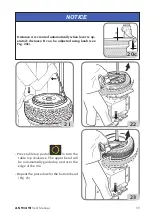

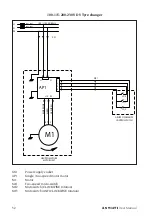

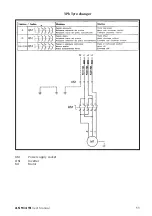

- Lock the vertical rod in this position.

- Remove valve core and connect the Doyfe con-

nector on the air hose to the valve stem (Fig. 31).

- Inflate the tyre by operating the proper pedal

(Fig. 31) at short intervals; check the pressure

gauge frequently to make sure that the pressure

NEVER exceeds the maximum pressure specified

by the tyre manufacturer.

If necessary:

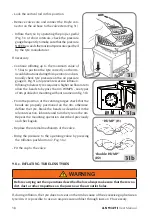

- Continue inflating up to the maximum value of

3.5 bar to position the tyre correctly on the rim.

Avoid distractions during this operation, and con-

tinually check tyre pressure on the air pressure

gauge (1, Fig. 31a) to prevent excessive inflation.

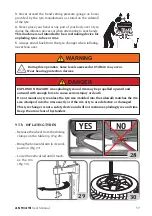

Inflating tubeless tyres requires a higher air flow-rate to

allow the beads to bypass the rim HUMPS - see types

of rim profiles for mounting without a camera in fig. 31b.

- From the position of the centring ridges check that the

beads are properly positioned on the rim; otherwise,

deflate the tyre, break the beads as described in the

relevant section, lubricate and turn the tyre on the rim.

Repeat the mounting operation described previously

and check again.

- Replace the internal mechanism of the valve.

- Bring the pressure to the operating value by pressing

the Inflation push-button (2, Fig. 31a).

- Fit the cap to the valve

9.8.c. INFLATINg TUBELEss TYREs

Before carrying out the operations described below, always make sure that there is no

dirt,

dust or other impurities on the jaws near the air outlet holes.

If, during inflation, the tyre does not seat on the rim because of the excessive gap between

tyre/rim, it is possible to use an air-pressure airblast through jaws on TI accessory.

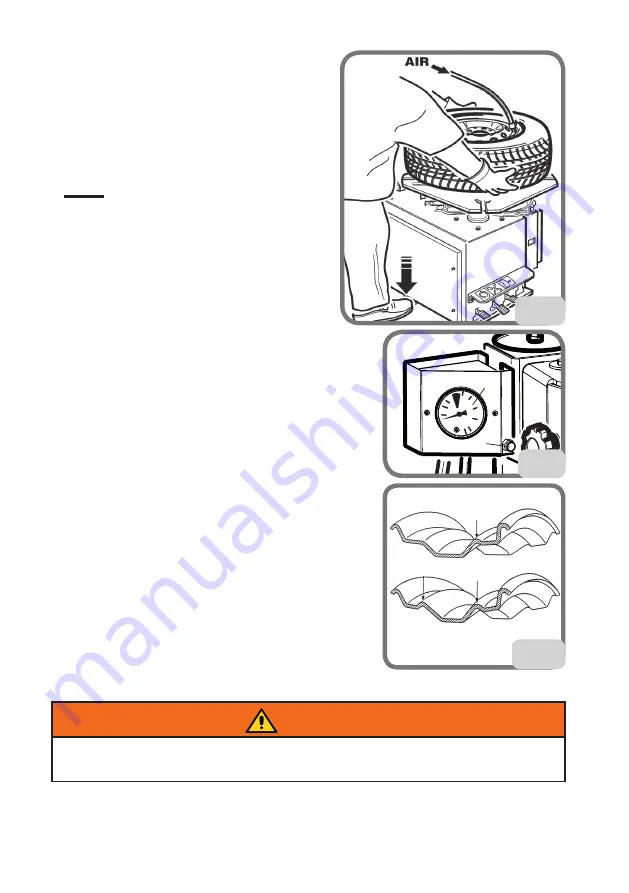

31a

1

2

“hUMP” (h)

“double hUMP”

(h2)

31b

WARNING

31