50

- E

nglIsh

-

Operator’s manual

vertical movement is independent and acti-

vated from the console; the disc horizontal

positioning is manual, mechanically activated

from the console and it allows the simultaneous

positioning of the bead breaker discs. Bead

breaking is ensured by the disc movement,

with a controlled penetration commanded by

an operator.

- A head, installed on a mobile column with a

rear opening, consists of a fixed supporting

nucleus that facilitates tyre mounting and a

pivoted mobile fixed nucleus that facilitates

an optimal tyre demounting without using the

bead lifter lever*.

* In a very few cases, an accessory supplied cal-

led manual “help” may be of use in simplifying

demounting where excessive lubricant has been

applied or for tyres coupled to special rims.

- A pedal-controlled pneumatically operated

wheel lift (optional) which loads and unloads

the wheel to and from the working position

The tyre changer has also enabled the achie-

vement of the following objectives:

- Minimised physical effort on the part of the

operator

- No risk of damage to rim and tyre

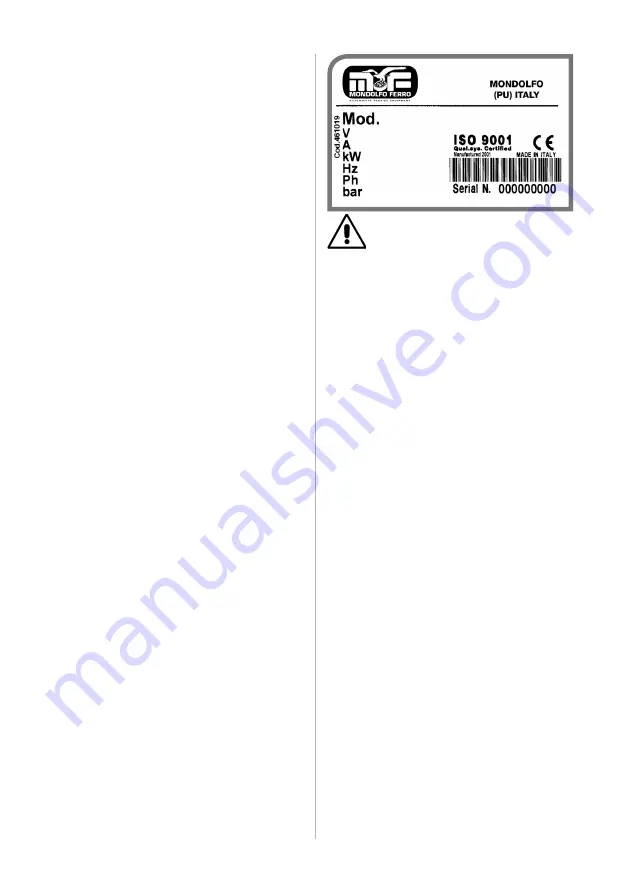

Each machine carries a plate with its identifi-

cation data and some technical data.

As well as the manufacturer’s details, it in-

dicates:

Mod. - Machine model; V - power supply voltage

in Volts;

A - Input voltage in Amperes; kW -

Absorbed power in kW;

Hz - Frequency in Hz;

Ph - Number of phases; bar - Operating pressure

in bar;

Serial No. - Machine serial number; ISO

9001 - Certification of the company's Quality

System;

EC - EC marking.

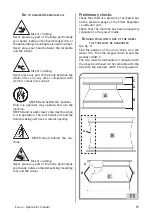

WARNING

It is forbidden to modify or remove the data

in the plate.

TECHNICAL DATA

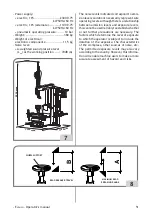

- Overall dimensions (see fig. 7):

• Length ...............................1235 min

– 1784 max

• Width.................................928 min –

2018 max

• Height ................................1210 min

– 2224 max

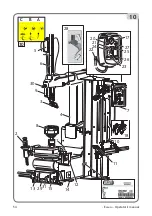

- Wheel dimension range:

• rim diameter ................ from 12” to 28”

• maximum tyre diameter .... 1080 mm (42”)

• max tyre width .............................15”

(from wheel supporting base)

- Turntable:

• resting side: ............................ flanged

• centring: ............................... on cone

• clamping: ..............pneumatic-automatic

• drive system: . 2-speed motor-inverter

unit

• rotation torque: ..................... 1200 Nm

• rotation speed: ......................6-15 rpm

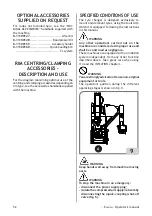

- Bead Breaking Unit:

• tool: ........................................ disc

• positioning in relation to rim: ...............

manual with mechanical clamping

• penetration: ............................guided

• maximum bead breaking range ..A = 670 mm

(fig.8)

• bead breaker stroke ..............B= 540 mm

(fig.8)

• bead breaking cylinder force: .......5500 N

- Wheel lifter: ...................... ON REQUEST

• lifting operation: .................. automatic

manual tilting

• activation: ......................... pneumatic

• lifting capacity: ......................... 85 kg

Summary of Contents for AQUILA RAPTOR

Page 34: ...34 Italiano Manuale d uso 35 a b c e d ...

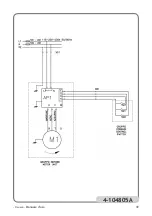

Page 39: ... Italiano Manuale d uso 39 4 104805A ...

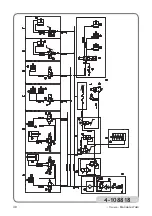

Page 40: ...40 Italiano Manuale d uso 4 108818 ...

Page 41: ...41 ...

Page 42: ...42 ...

Page 74: ...74 English Operator s manual 35 a b c e d ...

Page 79: ... English Operator s manual 79 4 104805A ...

Page 80: ...80 English Operator s manual 4 108818 ...

Page 81: ...81 ...

Page 82: ...82 ...

Page 114: ...114 Français Manuel d utilisation 35 a b c e d ...

Page 119: ... Français Manuel d utilisation 119 4 104805A ...

Page 120: ...120 Français Manuel d utilisation 4 108818 ...

Page 121: ...121 ...

Page 122: ...122 ...

Page 154: ...136 Deutsch Betriebsanleitung 35 a b c e d ...

Page 159: ... Deutsch Betriebsanleitung 123 4 104805A ...

Page 160: ...134 Deutsch Betriebsanleitung 4 108818 ...

Page 161: ......

Page 162: ...162 ...

Page 194: ...176 Español Manual de uso 35 a b c e d ...

Page 199: ... Español Manual de uso 199 4 104805A ...

Page 200: ...174 Español Manual de uso 4 108818 ...

Page 204: ...204 ...

Page 205: ...205 ...