58D6056

15

CSDV Series Direct Vent Gas Stove

VENTING INSTALLATION

INSTALLATION FOR HORIZONTAL TERmI-

NATION

1. Determine the route your horizontal venting will take.

NOTE:

The location of the horizontal vent termination on

the exterior wall must meet all local and national building

codes.

Snorkel terminations are available for terminations requir-

ing a vertical rise on the exterior of the building.

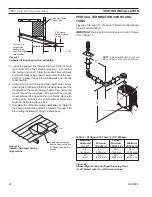

Figures 14

and 15.

Follow the same installation procedures used for

standard horizontal terminations. If installing the snorkel

termination below grade (basement applications), you must

provide proper drainage to prevent water from entering the

snorkel termination.

Figure 13.

Do not back fill around the

snorkel termination.

ST1137

snorkel install

12”

(305 mm)

Minimum

Snorkel

Figure 14 -

Snorkel Termination

ST1137

12”

(305 mm)

Minimum

ST1138

snorkel drainage

Snorkel

Adequate

Drainage

Figure 15 -

Snorkel Termination

with Drainage Pipe

ST1138

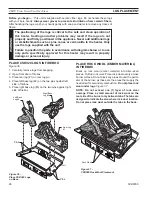

2. Rigid vent pipes and fittings have special twist-lock

connections. Assemble the desired combination of pipe

and elbows to the appliance adaptor with pipe seams

oriented towards the wall or floor.

Twist-lock Procedure: The female ends of the pipes

and fittings have three locking lugs (indentations).

These lugs will slide straight into matching slots on

the male end of adjacent pipes and fittings. Push the

pipe sections together and twist one section clockwise

approximately one-quarter turn until the sections are

fully locked.

Figure 16.

FP1953

rigid pipe

Female Locking

Lugs

Male Slots

FP1953

NOTE: Horizontal runs

of vent pipe must be

supported every three

(3) feet (914 mm). Use

wall straps for this

purpose.

Figure 16 -

Rigid Vent Pipe Connections

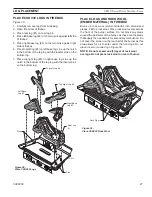

3. Attach vent pipe assembly to the stove. Set stove in

front of its permanent location to insure minimum clear-

ances. Mark the wall for a 9

Z\x

" (241 mm) square hole

(for noncombustible material such as masonry block or

concrete, a 7

Z\x

" [190 mm] diameter hole is acceptable).

Figure 17.

The center of the hole should line up with the

center line of the horizontal rigid vent pipe. Cut a 9

Z\x

" x

9

Z\x

" (241 x 241 mm) square hole through combustible

exterior wall (7

Z\x

" [190 mm] diameter hole if noncom-

bustible). Frame as necessary.

Figure 17

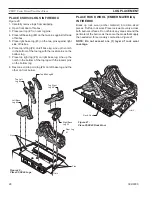

4. Apply a bead of non-hardening mastic around the

outside edge of vent cap. Position the vent cap in the

center of the 7

Z\x

" (190 mm) or 9

Z\x

" (241 mm) hole on the

exterior wall with the word “UP” on the vent cap facing

up. Insure proper clearance of 1" to combustibles is

maintained. Attach the vent cap with four wood screws

supplied.

Figure 18

For vinyl siding, stucco, or wood exterior use vinyl siding

standoffs between vent cap and exterior wall. The vinyl

siding standoff prevents excessive heat from melting the

vinyl siding material. Bolt the vent cap to the standoff. Apply

non-hardening mastic around outside edge of the standoff

instead of the vent cap assembly. Use wood screws pro-

vided to attach the standoff.

Figure 19

NOTE:

Replace the wood screws with appropriate fasteners

for stucco, brick, concrete, or other types of siding.