26

33D0237

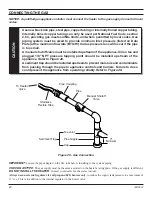

FLAME APPEARANCE

Flames from the pilot, front and rear burner should be visually checked as soon as the heater is installed.

In addition, periodically check the flames visually during operation.

CHECKING THE PILOT FLAME

The pilot flame must always be present when the heater is in operation.

It should just touch the top of the

thermocouple tip for natural. Refer to Figure 37 and 39 for correct pilot flame.

If the pilot flame does not touch the thermocouple, then the main burner cannot function reliably. Refer to Figure 38 and 40

for incorrect shape of pilot flame.

MILLI-VOLT CONTROL

Figure 37 - Correct Appearance of Pilot Flame

Figure 38 - Incorrect Appearance of Pilot Flame

MANUAL AND THERMOSTAT CONTROL

Figure 39 - Correct Appearance of Pilot Flame

Figure 40 - Incorrect Appearance of Pilot Flame

Thermocouple

for Natural

Thermocouple

for LP

Thermocouple

for LP

Thermocouple

for Natural

Thermocouple

for Natural

Thermocouple

for Natural

Thermocouple

for LP

Thermocouple

for LP