57D0016

19

CHECKING GAS PRESSURE

1. Check gas type. The gas supply must be the same as

stated on the applianceʼs rating decal. If the gas supply

is different from the fireplace, STOP! Do not install

the appliance. Contact your dealer immediately.

2. Install and attach 30" (762mm) flex line provided with

on this appliance to

1

/

2

" gas line.

3. After completing gas line connection, purge air from

gas line and test all gas joints from the gas meter to

the fireplace for leaks. Use a soap and water solution

or a gas sniffer.

4. To adjust flame height, turn HI/LO knob to HI to get

maximum pressure to burner. Turn HI/LO knob to LO

to get minimum pressure.

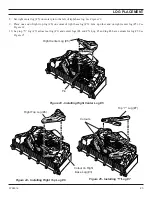

5. To check gas pressures at valve, turn captured screw

counter clockwise 2 or 3 turns and then place tubing to

pressure gauge over test point. Turn unit to high.

See

Figure 16.

After taking pressure reading, be sure and

turn captured screw clockwise firmly to reseal. Do not

over torque. Check test points for gas leaks with a soap

and water solution or an electronic gas leak detector.

Do not use open flame to check for

gas leaks.

W

ARNING

Figure 16 - Gas Pressure Check at Gas Valve

Pressure

Test “IN”

Pressure

Test “OUT”

HI/LO

Knob

Pilot Adjustment

Screw