54

56D2161

STANDING PILOT IGNITION

TROUBLESHOOTING

SYMPTOM

POSSIBLE CAUSE

ACTION

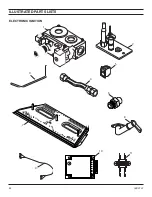

1. Spark ignitor

will not light

pilot after

repeated

triggering of

piezo.

A. Wire disconnected.

A. Open door and check to make sure wire is connected to ignitor.

B. Defective ignitor.

B. Check for spark at electrode and pilot. If no spark and electrode wire is prop-

erly connected, replace pilot assembly.

C. No gas or low gas pressure.

C. Check remote/manual shut off valve from fireplace. Low pressure can be

caused by bent lines, restricted lines, low pressure line pressure. Consult with

plumber or gas supplier.

D. No Propane/LPG in tank

D. Check Propane/LPG tank. Refill tank.

2. Pilot will not

stay lit after

carefully fol-

lowing light-

ing instruc-

tions.

A. Defective thermocouple

A. Check that thermocouple flame impinges on thermocouple. Clean and/or

adjust pilot for maximum flame impingement. Ensure that the thermocouple

connection at the gas valve is fully inserted and tight.

Disconnect the thermocouple from the valve, place one millivolt lead wire on

the tip of the thermocouple and the other meter lead wire on the thermocouple

copper lead. Start the pilot and hold the valve knob in. If the millivolt reading

is less than 15 mV, replace pilot assembly.

B. Defective valve

B. If thermocouple is producing more than 15 mV, replace faulty valve.

3. Pilot burn-

ing, valve

knob turned

to “ON”,

switch is

turned to

“ON” or

“RS”, but

burner will

not ignite.

A. Defective switch, wall switch,

remote control or wire

A. Check switch and wire for proper connection. Place jumper wires across ter-

minals of switch. If burner comes on, replace defective switch. If the switch is

OK, repeat the same procedure on remote control If burner comes on, replace

remote control.

Place jumper wire across wire at gas valves (terminals marked TH and TP/TH).

If burner comes on, wires are faulty or connections are bad. Replace wire.

B. Pilot flame too small

B. If pilot flame is not close enough to the thermopile, adjust pilot flame.

C. Defective or malfunctioning

thermopile

C. Check thermopile wire connections to make sure all are tight and that the

thermopile is fully inserted into pilot assembly. Check thermopile with a mil-

livolt meter. Connect leads to TP and TP/TH terminals on the control valve.

If meter reading is below 325 mV, replace pilot assembly.

D. Defective valve

D. Turn valve knob to “On” and switch to “ON.” Take a reading at the thermopile

leads (TP & TP/TH) on the valve. If the meter reads greater than 175 mV and

the burner does not light, replace defective valve

4. Frequent

pilot outage

problem.

A. Pilot flame may be too high or

too low, causing pilot safety to

drop out

A. Clean and adjust the pilot flame for maximum flame impingement on ther-

mocouple.

5. The pilot and

main burner

extinguish

while in

operation

A. Inner vent pipe leaking exhaust

gases back into system

A. Check for flue product leak. Replace defective pipe section.

B. Horizontal vent improperly

pitched

B. Check horizontal-venting piping is running upward 1/4" per foot. Do not

run the pipe level or downward.

C. Improper vent cap installation

C. Check for proper installation and freedom from debris or blockage

SYMPTOM

POSSIBLE CAUSE ACTION

1. Glass Soots

A. Flame impingement

on logs

A. Install log set per the instructions

Inspect the injector and air intake area. Make sure this area does not have any

blockage from debris and clean.

Check gas supply.

2. Flame burn blue

and lifts off

burner (ghosting)

A. Insufficient oxygen

being supplied

A. Ensure that the vent cap is installed properly and free of debris. Ensure that the

vent system joints are tight and have no leaks. Ensure that no debris has been

blocking the inner air intake at the bottom back of the combustion chamber.

Ensure that the glass is properly secure and latch.

GENERAL TROUBLESHOOTING