32D1999

17

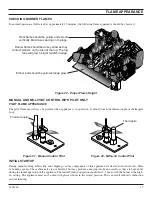

Rear flame should be yellow and extend

vertically. Maximize spacing on top logs.

Burner flame should become yellow as they

contact embers on the face of the log. The log

face will glow a bright reddish orange.

Ember bed should be yellow/orange glow.

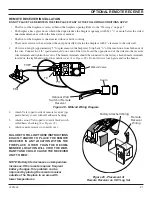

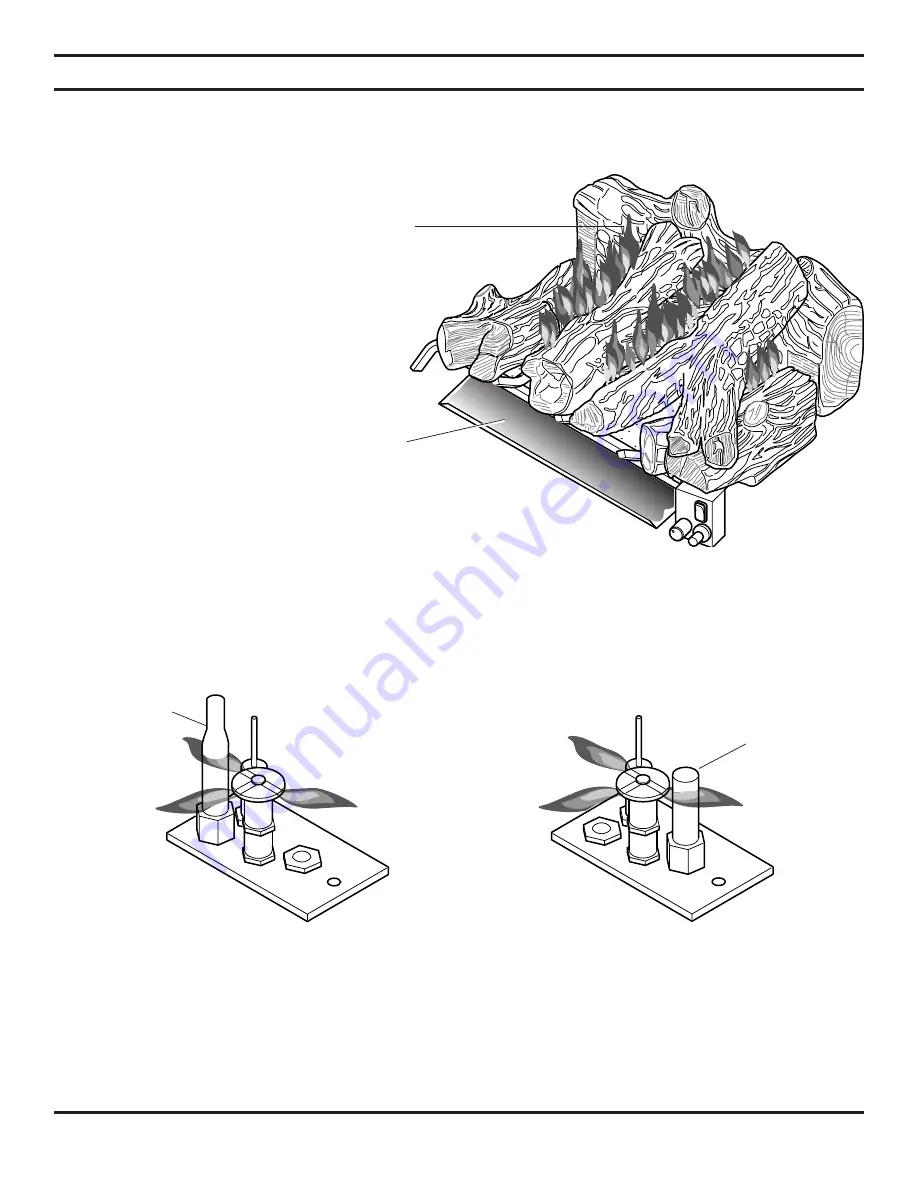

Thermopile

Thermocouple

Figure 21 - Manual Control Pilot

Figure 22 - Milli-volt Control Pilot

FLAME APPEARANCE

CHECKING BURNER FLAMES

In normal operation at full rate after appoximately 15 minutes, the following flame appearance should be observed.

MANUAL AND MILLIVOLT CONTROL WITH PILOT ONLY

PILOT FLAME APPEARANCE

The pilot flame must always be present when appliance is in operation. It should touch the thermocouple or thermopile

body.

INITIAL STARTUP

During manufacturing, fabricating and shipping, various components of this appliance are treated with certain oils, films

or bonding agents. These chemicals are not harmful, but may produce annoying smoke and smells as they are burned off

during the initial operation of the appliance. The initial break-in operation should last 2-3 hours with the burner at the high-

est setting. The appliance must not be used with glassed doors in the closed position. This can result reduced combustion

and overheating.

Figure 20 - Proper Flame Height