FP2781

millivolt valve

Test Port

"OUT"

12

VFC Vent Free Fireplace System

Monessen • VFC 24/32 Owner Manual • 20308011 • Rev A • 06/16

CONNECTING THE GAS LINE

NOTICE:

A qualified gas appliance installer must connect

the heater to the gas supply. Consult all local codes.

GAS LINE & PRESSURE

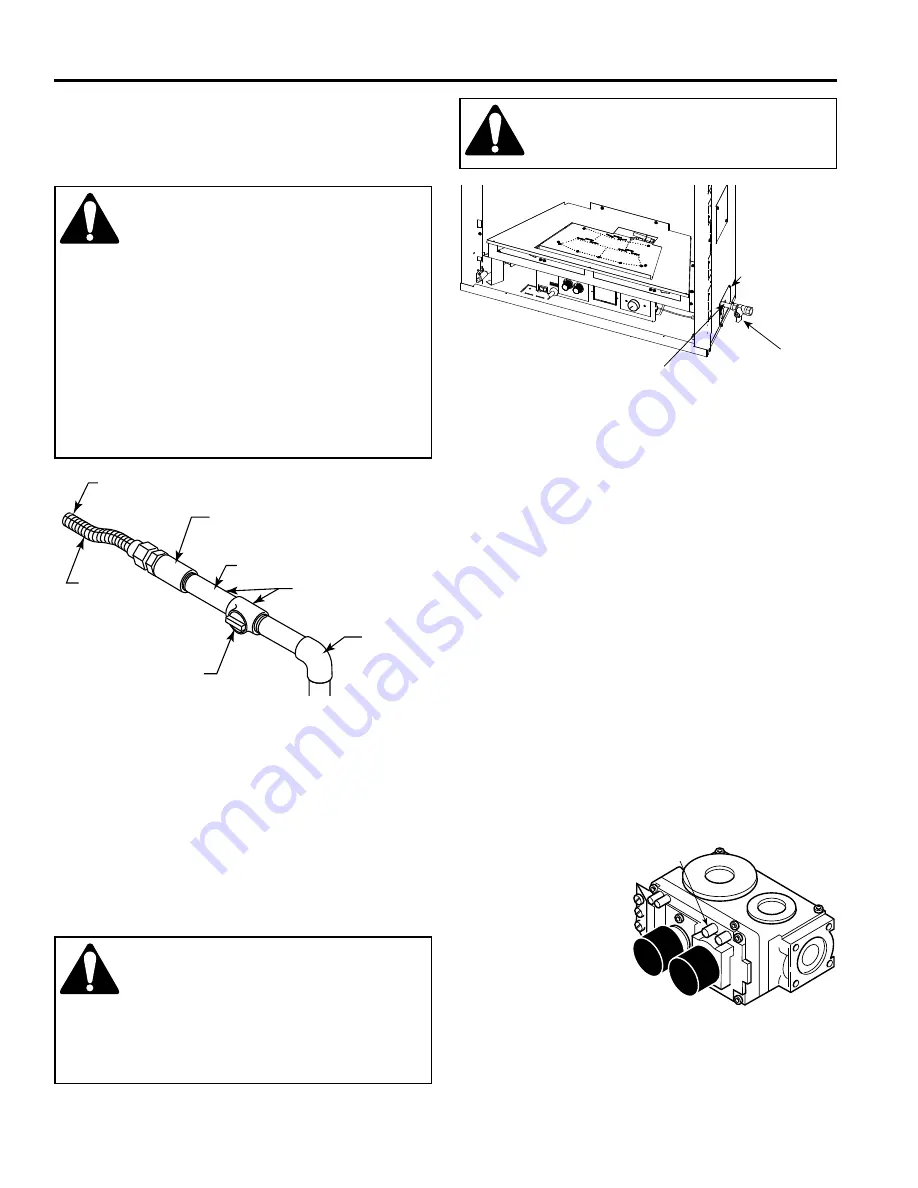

FP2447

gas connection

3” Min.

To Fireplace

Pipe Coupling

Stainless

Flexible Tube

Pipe

Locations Pressure

Tapping Point Instal-

lation

Manual Shutoff

Valve

Gas Supply

Inlet

Figure 11.

Gas

Connection

IMPORTANT:

Loosen the pipe adapter on the flex tube

before installing to the system piping.

Always use an external regulator for all propane/LPG heat-

ers only, to reduce the supply tank pressure to a maximum

of 13" w.c. This is in addition to the internal regulator in the

heater valve.

To reach factory installed flex line, go through access door

on right or left side of firebox.

Figure 12.

Access Holes

Manual Gas Shutoff

(Recommended Outlet

Positioned Vertical)

Stainless Flex Line

Access Door

for Gas Line

WARNING:

Connecting directly to an

unregulated propane/LPG tank can

cause an explosion

WARNING: Use new black iron or

steel pipe. Internally tinned copper or

copper tubing can be used per National

Fuel Code, section 2.6.3, providing gas meets

hydrogen sulfide limits, and where permitted by

local codes. Gas piping system must be sized to

provide minimum inlet pressure (Listed on Data

Plate) at the maximum flow rate (BTU/hr). Undue

pressure loss will occur if the pipe is too small.

A manual shutoff valve must be installed

upstream of the appliance. Union tee and

plugged 1/8" NPT pressure tapping point should

be installed upstream of the appliance.

Figure 11

WARNING: CHECK GAS TYPE: The

gas supply must be the same as stated

on the heater’s rating plate. If the gas

supply is different, DO NOT INSTALL THE

HEATER. Contact your dealer for the correct

model. Connecting to the wrong gas type may

result in property damage or personal injury.

The stainless flex line is on the right side facing the fire-

place and can connect to either a 3/8 NPT female or 1/2

NPT male pipe. To connect from the opposite side, route

the pipe under the rear portion of the unit.

Test all gas joints from the gas meter to the heater valve for

leaks using a gas analyzer or soap and water solution after

completing connection.

DO NOT USE AN OPEN FLAME.

Check the gas pressure with the appliance burning and

the control set to

HIGH

.

Open control access door on either side of unit to find valve

and regulator referred to below. Figure 12

CHECKING GAS PRESSURE – MILLIVOLT

CONTROL

Figure 12

The valve regulator controls the burner pressure which

should be checked at the pressure test point.

Turn captured screw counter clockwise two or three turns

and then place tubing

to pressure gauge over

test point (Use test point

“OUT” closest to con-

trol knob). After taking

pressure reading, be

sure and turn captured

screw clockwise firmly

to re-seal. Do not over

torque. Check for gas

leaks.

Figure 13.

Pressure Test Point Location Millivolt Control

Summary of Contents for VFC24

Page 45: ......