2

Choosing a Location for SMU

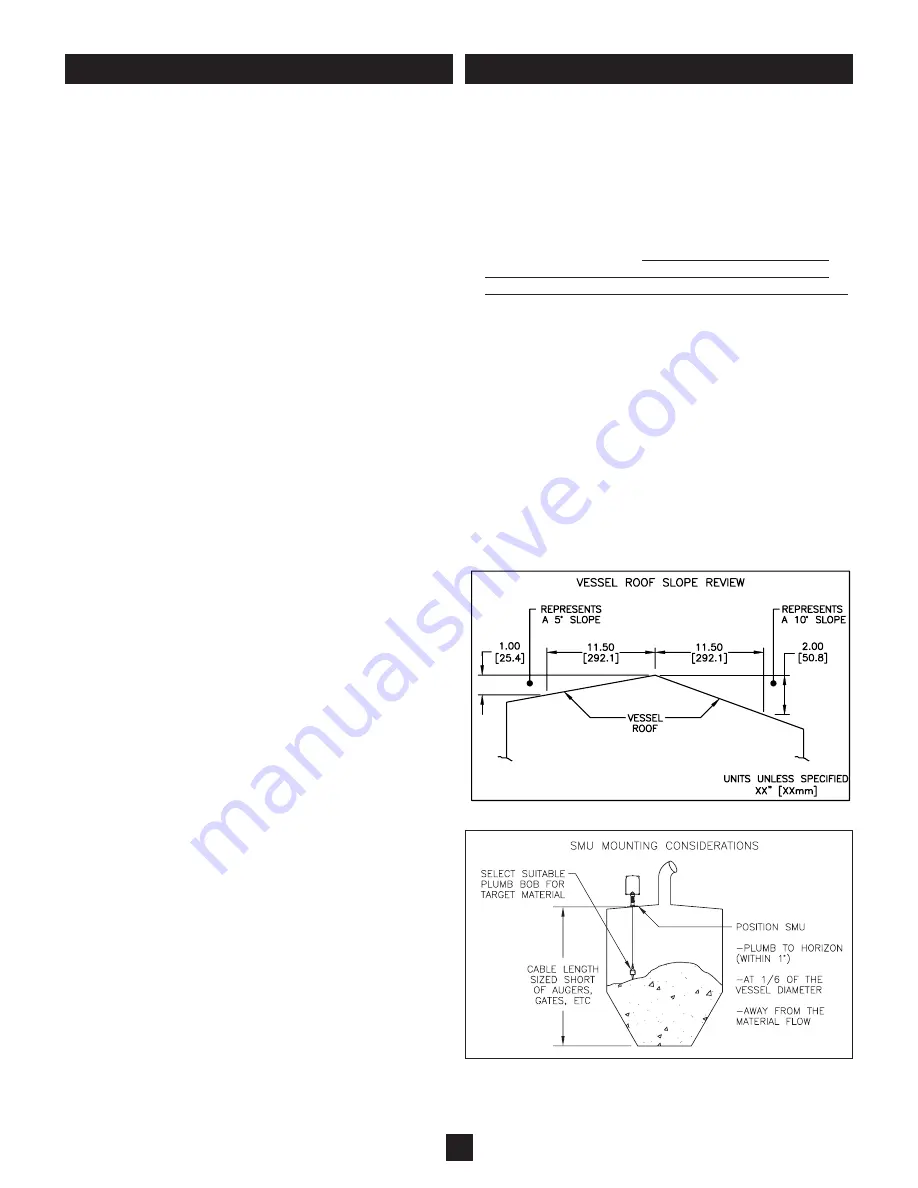

(See Figure 1 and 2)

1) Environment

- SMUs can be configured for ordinary locations

or hazardous locations. The application location must comply

with the SMU classification listed in the specifications. All

SMUs are weatherproof and therefore suitable for outdoor

applications. Note the temperature limits in the specifications.

2) Placement

- Consider the effect that the material's angle of

repose will have on the operation. The SMU will measure the

material height directly below its mounting. For center-fill and

center-discharge vessels, the volumetric average can be

attained by mounting the SMU at a distance equal to 1/6

the vessel diameter away from the outer edge of the vessel

.

Mount the SMU away from internal obstructions and away from

areas where in-flow of material may directly contact the

plumb bob during operation.

Ensure the cable length will not

cause plumb bob extension into augers, slide gates or feed-

ers.

This measurement device cannot factor varying angles

of repose in it’s calculated volumetric displays representing

the material being measured if it is solid as opposed to liquid.

3) Plumb

- The SMU must be mounted plumb (perpendicular to

the ground) within 1 degree. Do not mount the SMU on an

angle. Install an adapter or consider use of a 5 degree or 10

degree flange which can be supplied by Monitor. If the angle

of the roof is unknown, use Figure 1 to approximate. Each 1

inch (25.4 mm) of drop per 11.5 inches (292 mm) of horizon-

tal movement represents approximately five degrees.

PRE-INSTALL ATION CONSIDERATIONS

Figure 1

Figure 2

DIMENSIONS ARE SHOWN IN INCHES WITH MILLIMETER EQUIVALENT IN BRACKETS

Once a measurement cycle is initiated, the

Silo

Patrol

®

SE

SE

sensor (SMU) “smart” motor system controls the descent

of a plumb bob, attached to a heavy-duty stainless steel

cable, into the vessel. The SMU measures the amount of

cable dispensed via its unique optical sensing system.

The SMU’s optic system is completely sealed from the

internal environment of the electronics compartment,

which is isolated and sealed from material ingress in the

mechanical compartment, to ensure long-term reliable

operation.

The descent of the bob is maintained at an optimal speed

by the “smart” motor control system, which contributes to

maximizing the motor life. In conjunction with the unique

dual optical sensing system, the “smart” motor control sys-

tem guarantees that the bob will stop when it contacts the

material surface and eliminates the need for a mechanical

brake. When the bob reaches the material surface, the

SMU reverses the direction of the motor and transmits the

distance value.

In addition, the “smart” motor control system now has an

enhancement feature called Descend-Assist. This feature

would be used if a particular application may be causing

the plumb bob to “cling” to the socket. See Pg. 10 (RS-485)

or Pg. 13 (Analog) of this document to Turn “ON” Descend-Assist

through the ConfigureSensor app in the MISC SETTINGS sec-

tion.

During the ascent of the bob, the SMU measures the

amount of cable gathered and controls the speed of

ascent. This ensures proper cable wrapping in the patent-

ed storage reel and tangle-free operation.

The SMU also includes a Hall effect sensor array that

monitors the movement and position of the swing-arm that

controls the absorption of slack in the cable system during

descent and ascent. The SMU is smarter than ever and

uses this technology to control the cable and plumb bob

travel to ensure reliability of the measurement cycle, even

with harsh changing conditions in the most severe applica-

tions.

The SMU has two output types available that must be

selected at the time of purchase: RS-485 version and

Analog 4-20mA version. The

Silo

Patrol

SE

SE

system, if so

equipped, will also generate auxiliary analog and/or relay

outputs. RS485 communications can be accomplished via

hardwiring or with wireless transceivers.

PRINCIPLE OF OPERATION