3

General

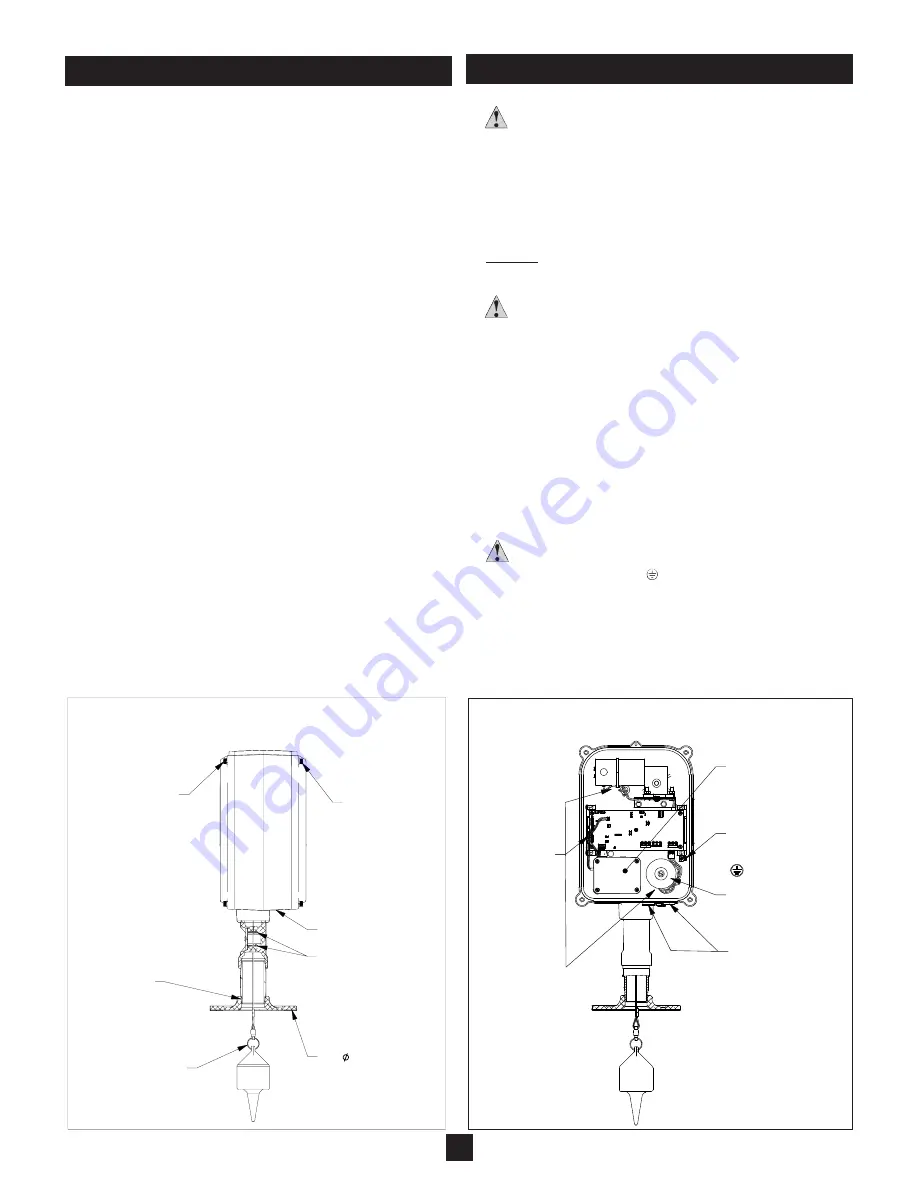

(All SMUs) (See Figure 4)

1) Dust-Ignition-Proof Precautions -

When installing a haz-

ardous location SMU, observe all regulations applicable to

local codes. Do not open the enclosure when an explosive

atmosphere is present. When reattaching covers, ensure that

gaskets are clean and that screws are fully engaged. Tighten

in a criss-cross pattern.

2) Factory Wiring/Compartment

- The SMU motor, encoder,

and swing arm sensor leads are prewired to the PCB module.

DO NOT alter or make additional external connection to these

terminals. Doing so will likely cause damage to the SMU. Do

not remove cover protecting the optical sensing compartment.

3) Permanently Connected Equipment

- Disconnecting

devices shall be included in the system installation. In instal-

lations where multiple circuits are used (i.e. independent cir-

cuits for power input, cycle, count, sound and lockout), indi-

vidual disconnects are required. The disconnects shall be

within close proximity of the equipment, accessible to

operators, and marked appropriately. Assure the disconnect

ratings are appropriately sized for the circuit protected

(See Specifications).

4) Circuit Separation

- Two cable entry locations are provided

to aid in maintaining separation of "hazardous live" and limit-

ed circuits. It is required that all wiring have an insulation

rating of 300V minimum, and a temperature rating of 80˚ C

(176˚ F) minimum.

5) Protective Earthing

- Each SMU is provided with a "pro-

tective conductor terminal" which shall be terminated to the

local earth ground potential. Select a wire size that can carry

in excess of the sum of all circuit's maximum amperage.

Figure 4

TR

TTR

ANSFOR

TRA

TRAN

TRANS

TRANSF

TRANSFO

TRANSFORMER

TRANSFORM

TRANSFORME

TRANSFORMER

(230VAC MO

TRANSFORMER

(

TRANSFORMER

(2

TRANSFORMER

(23

TRANSFORMER

(230

TRANSFORMER

(230V

TRANSFORMER

(230VA

TRANSFORMER

(230VAC

TRANSFORMER

(230VAC

TRANSFORMER

(230VAC M

TRANSFORMER

(230VAC MODELS O

TRANSFORMER

(230VAC MOD

TRANSFORMER

(230VAC MODE

TRANSFORMER

(230VAC MODEL

TRANSFORMER

(230VAC MODELS

TRANSFORMER

(230VAC MODELS

TRANSFORMER

(230VAC MODELS ON

TRANSFORMER

(230VAC MODELS ONL

TRANSFORMER

(230VAC MODELS ONLY)

TRANSFORMER

(230VAC MODELS ONLY

TRANSFORMER

(230VAC MODELS ONLY)

PRO

P

PR

PROT

PROTE

PROTECT

PROTEC

PROTECTIVE

PROTECTI

PROTECTIV

PROTECTIVE

C

PROTECTIVE

COND

PROTECTIVE

CO

PROTECTIVE

CON

PROTECTIVE

CONDUC

PROTECTIVE

CONDU

PROTECTIVE

CONDUCTOR

PROTECTIVE

CONDUCT

PROTECTIVE

CONDUCTO

PROTECTIVE

CONDUCTOR

TER

PROTECTIVE

CONDUCTOR

T

PROTECTIVE

CONDUCTOR

TE

PROTECTIVE

CONDUCTOR

TERM

PROTECTIVE

CONDUCTOR

TERMI

PROTECTIVE

CONDUCTOR

TERMIN

PROTECTIVE

CONDUCTOR

TERMINAL

PROTECTIVE

CONDUCTOR

TERMINA

PROTECTIVE

CONDUCTOR

TERMINAL

OP

O

OPTI

OPT

OPTIC

OPTICA

OPTICAL

OPTICAL

CO

OPTICAL

C

OPTICAL

COMPART

OPTICAL

COM

OPTICAL

COMP

OPTICAL

COMPA

OPTICAL

COMPAR

OPTICAL

COMPARTM

OPTICAL

COMPARTMEN

OPTICAL

COMPARTME

OPTICAL

COMPARTMENT

OPTICAL

COMPARTMENT

DO

OPTICAL

COMPARTMENT

D

OPTICAL

COMPARTMENT

DO N

OPTICAL

COMPARTMENT

DO

OPTICAL

COMPARTMENT

DO NO

OPTICAL

COMPARTMENT

DO NOT

OPTICAL

COMPARTMENT

DO NOT REMO

OPTICAL

COMPARTMENT

DO NOT

OPTICAL

COMPARTMENT

DO NOT R

OPTICAL

COMPARTMENT

DO NOT RE

OPTICAL

COMPARTMENT

DO NOT REM

OPTICAL

COMPARTMENT

DO NOT REMOVE

OPTICAL

COMPARTMENT

DO NOT REMOV

OPTICAL

COMPARTMENT

DO NOT REMOVE

CO

OPTICAL

COMPARTMENT

DO NOT REMOVE

C

OPTICAL

COMPARTMENT

DO NOT REMOVE

COVER

OPTICAL

COMPARTMENT

DO NOT REMOVE

COV

OPTICAL

COMPARTMENT

DO NOT REMOVE

COVE

OPTICAL

COMPARTMENT

DO NOT REMOVE

COVER

CABLE

C

CA

CAB

CABL

CABLE

ENTRIES

CABLE

E

CABLE

EN

CABLE

ENT

CABLE

ENTR

CABLE

ENTRI

CABLE

ENTRIE

CABLE

ENTRIES

ELECTRICAL INSTALLATION

EEL

ELE

ELEC

ELECT

ELECTR

ELECTRI

ELECTRIC

ELECTRICA

ELECTRICAL

ELECTRICAL

ELECTRICAL I

ELECTRICAL IN

ELECTRICAL INS

ELECTRICAL INST

ELECTRICAL INSTA

ELECTRICAL INSTAL

ELECTRICAL INSTALL

ELECTRICAL INSTALLA

ELECTRICAL INSTALLAT

ELECTRICAL INSTALLATI

ELECTRICAL INSTALLATIO

ELECTRICAL INSTALLATION

FACT

ELECTRICAL INSTALLATION

F

ELECTRICAL INSTALLATION

FA

ELECTRICAL INSTALLATION

FAC

ELECTRICAL INSTALLATION

FACTO

ELECTRICAL INSTALLATION

FACTORY WIRIN

ELECTRICAL INSTALLATION

FACTOR

ELECTRICAL INSTALLATION

FACTORY

ELECTRICAL INSTALLATION

FACTORY

ELECTRICAL INSTALLATION

FACTORY W

ELECTRICAL INSTALLATION

FACTORY WI

ELECTRICAL INSTALLATION

FACTORY WIR

ELECTRICAL INSTALLATION

FACTORY WIRI

ELECTRICAL INSTALLATION

FACTORY WIRING

ELECTRICAL INSTALLATION

FACTORY WIRING

DO

ELECTRICAL INSTALLATION

FACTORY WIRING

D

ELECTRICAL INSTALLATION

FACTORY WIRING

DO N

ELECTRICAL INSTALLATION

FACTORY WIRING

DO

ELECTRICAL INSTALLATION

FACTORY WIRING

DO NO

ELECTRICAL INSTALLATION

FACTORY WIRING

DO NOT

ELECTRICAL INSTALLATION

FACTORY WIRING

DO NOT ALT

ELECTRICAL INSTALLATION

FACTORY WIRING

DO NOT

ELECTRICAL INSTALLATION

FACTORY WIRING

DO NOT A

ELECTRICAL INSTALLATION

FACTORY WIRING

DO NOT AL

ELECTRICAL INSTALLATION

FACTORY WIRING

DO NOT ALTE

ELECTRICAL INSTALLATION

FACTORY WIRING

DO NOT ALTER!

ELECTRICAL INSTALLATION

FACTORY WIRING

DO NOT ALTER

ELECTRICAL INSTALLATION

FACTORY WIRING

DO NOT ALTER!

MECHANICAL INSTALL ATION

SMU Mounting

(See Figure 3)

1) Location

- Select a mounting location in accordance with the

Pre-Installation Considerations.

2) Preparation

- If using Monitor's K-style flange (flat, 5 degree

or 10 degree pitch), cut a 5-1/2 inch (133 mm) diameter cen-

ter hole and drill six 11/32 inch (9 mm) diameter mounting

holes (for 5/16" bolts) on a 7 inch (178 mm) bolt circle.

3) Mounting

- Install gasket, place plumb bob in center hole and

secure flange with 5/16" bolts.

4) Other flanges

- If mounting of the SMU is done via an ANSI

or similar flange, ensure that the center bore on the flange is

sized to mate with the 2" NPT standpipe.

5) Non-standard plumb bobs

- Plumb bobs greater than 5 1/2

inch (133 mm) in diameter must be attached to the SMU after

mounting. A standard plumb bob is provided with each SMU.

To change the plumb bob, first install the SMU which will

ensure that the cable will not become tangled during the plumb

bob exchange. Use the "motor control switches" to lower the

standard plumb bob in the vessel (See Setup section for

details). Then pull the standard plumb bob out through an

access hatch/vent. All bobs are held on to the cable by a split-

ring fastener. Remove standard plumb bob from split-ring and

reattach appropriate plumb bob. Gently release plumb bob

into vessel, then press the "reset" switch on the SMU logic

circuit board to pull plumb bob back to start position.

6) Cover attachment

- The side covers are retained by 4

socket head cap screws. These 5/16 -18 screws can be

removed with a 1/4" Allen wrench. The cover with a lens is

for the electrical side of the unit.

Note:

A hazardous location

SMU

IS NOT

available with a lens-equipped cover.

ATEX and IECEx Supplemental Instructions:

Do not open the enclosure when an explosive atmosphere is present.

Whenever the covers are removed for servicing, if ANY PORTION of the

cover gasket adheres to the housing face, a new cover gasket must be

reinstalled prior to replacing the covers. The gasket must be installed such

that it is bottomed out in the groove of the cover. See Bulletin 344K

(Mechanical Installation) for further instructions.

Figure 3

SMU MOUNTING &

PLUMB BOB ATTACHMENT

[

XXmm

]

XX"

UNITS UNLESS SPECIFIED

A

.34 [9.0] HOLES

CONDUIT ENTRIES

(2) 3/4" NPT

S.H.C.S., 5/16

MECHANICAL SIDE

WIPERS

(4) SCREW,

(FOR 5/16" BOLTS)

2" NPT

CONNECTION

ON 7.00 [178.0] B.C.

ATTACHMENT

SPLIT RING FOR

PLUMB BOB

(6)

(4) SCREW,

S.H.C.S., 5/16

ELECTRICAL SIDE

ELECTRICAL INSTALL ATION