Delta softstart RevB17 26-9-17

8

4.0 SAFETY

1

Never use a machine in a

faulty condition

and always report any damage.

2

Only

trained engineers

may remove any part from this machine that requires a

tool to do so.

3

Always

ensure hands are dry

before touching any electrical appliance

(including cable, switch and plug).

4

All operatives

must be fully trained

.

5

People undergoing training on the machine must be

under direct supervision

.

6

Do not operate the machine with any panels or guards removed

.

7

No loose clothing

or jewellery

should be worn while operating the machine.

8

Switch off power at the mains isolator when machine is not in use and before

carrying out any cleaning or maintenance.

ALL CLEANING AND MAINTENANCE OPERATIONS MUST BE MADE WITH

MACHINE DISCONNECTED FROM THE POWER SUPPLY.

9

The bakery manager or the bakery supervisor must carry out daily safety

checks on the machine.

10

Do not operate machine without hopper template fitted correctly.

5.0 INSTALLATION

1

Ensure that the depositor is connected to the correct electric supply as specified

on the serial number plate on the rear of the machine.

2

Ensure that the correct fuse rating is fitted in the electrical supply to the DELTA

a 13A single phase supply fused at 20A anti-surge or 20A type D MCB is

required.

TEMPLATE CORRECTLY FITTED

TO HOPPER

Summary of Contents for DELTA DEPOSITOR 40

Page 2: ...Delta softstart RevB17 26 9 17 2...

Page 22: ...Delta softstart RevB17 26 9 17 22 17 0 DELTA DEPOSITOR RECOMMENDED SPARES LIST...

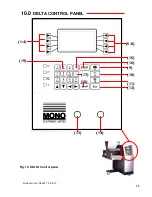

Page 27: ...Delta softstart RevB17 26 9 17 27 18 0 ELECTRICAL DIAGRAMS...

Page 28: ...Delta softstart RevB17 26 9 17 28...

Page 29: ...Delta softstart RevB17 26 9 17 29...

Page 30: ...Delta softstart RevB17 26 9 17 30...

Page 31: ...Delta softstart RevB17 26 9 17 31...

Page 32: ...Delta softstart RevB17 26 9 17 32...

Page 33: ...Delta softstart RevB17 26 9 17 33...

Page 34: ...Delta softstart RevB17 26 9 17 34...

Page 35: ...Delta softstart RevB17 26 9 17 35...

Page 36: ...Delta softstart RevB17 26 9 17 36...