This optional paint guide is provided if you

choose to detail paint your model.

Ce guide de peintures vous sera fourni si vous choisissez de

peindre votre modèle en détail.

Aluminum

Flat Black

Gloss Black

Red

Silver

Steel

Tan

Transparent Red

Turn Signal Amber

White

Aluminium

Noir mat

Noir brilliant

Rouge

Argent

Acier

Havane

Transparent Red

Feu clignotant de

direction ambre

Blanc

If you have any questions or comments, call our hotline at:

(800) 833-3570

or, please write to:

Revell-Monogram Consumer Service Department, 725 Landwehr Road, Northbrook, Illinois 60062

Be sure to include the plan number (85224200200), part number, description, your return address and phone number.

Visit our website: www.revellmonogram.com

KIT 2242

85224200200

* REPEAT SEVERAL TIMES

* A REPETER PLUSIEURS FOIS

* CEMENT TOGETHER

* A COLLER

* ALTERNATIVE ASSEMBLY

* ENSEMBLAGE ALTERNATIVE

* REMOVE AND THROW AWAY

* A RETIRER ET JETER

* DO NOT CEMENT

* NE PAS COLLER

* OPTIONAL PARTS

* PIECES EN OPTION

* DECAL

* DECAL COMANIE

REVELL-MONOGRAM, LLC Northbrook, IL. Copyright © 2004. All rights reserved. Made in China

The Pontiac Fiero had a history of only five model years-1984 through

1988. Even though over fifteen years have passed since the last Fiero rolled

off the production line, the car still has a sizable following of fiercely loyal

enthusiasts.

The story behind the Fiero’s development actually started with then

Pontiac general manager John DeLorean in 1967. Still fresh from the suc-

cess of the Pontiac GTO™, another car he championed, DeLorean liked the

idea of a mid-engined small car with a non-metal body. GM management,

already dealing with issues in the development of the already delayed next

generation Corvette®, killed the idea.

That’s where things stayed until 1978, when the Pontiac division revived

the mid-engined car idea. At this time, the US was in the middle of a gaso-

line shortage and American car manufacturers found themselves low on fuel

efficient cars that the public actually wanted to buy. The Fiero was to be

positioned as an exciting car that still was an economy car. Names consid-

ered at the time for the new car included Pegasus, Sprint and Fiamma, that

last name an Italian word that the marketing staff thought would not go over

well with the public. Still, when a GM employee stumbled upon "Fiero" in an

Italian dictionary (it means "very proud"), everyone gave it a thumbs up.

When the Fiero first appeared in late 1983 as a ’84 model, it had but one

engine choice, a 2.5 liter 4 cylinder. While many immediately complained

that the car did not have nearly enough power, for many others it was just

perfect as it was. While Pontiac hoped to sell 80,000 units in the car’s first

year, actual sales turned out to be over 100,000, insuring the Fiero’s profit-

ability. Another high point was the announcement that the Fiero would be

the Pace Car for the following year’s Indy 500®, the only mid-engined car

and one of the very few 4 cylinder cars to pace the race. In addition, 2,000

Pace Car replicas were offered to the public.

Development moved along quickly after that, with the GT model being

introduced early in 1985. The GT, the subject of this Revell kit, included a

2.8 liter V6 engine for more power, larger wheels and tires and the rounded

front end that first appeared on the Pace Car. A year later, the fastback body

style was introduced.

Things took a strange turn in the 1988 model year. Many thought the

‘88s were the best Fieros yet and new colors and options including leather

interior and the rare T-Tops (only 1,250 built) were made available. A pro-

totype ’89 model was even built. Yet, GM discontinued the Fiero suddenly

after the 1988 models. To this day, many Fiero enthusiasts debate as to

why the car was dropped. The last two Fieros were produced on August 16,

1988 and were both given to employees at the plant. The Fiero story didn’t

end on that day, however, and many clubs and companies offering parts and

technical assistance still abound.

‘85 Fiero GT

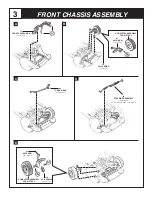

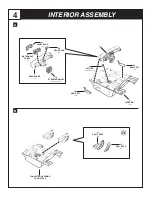

* Study the assembly drawings.

* Each plastic part is identified by a number.

* In the assembly drawings, some parts will be

marked by a star (

★

) to indicate chrome

plated plastic.

* For better paint and decal adhesion, wash

the plastic parts in a mild detergent solution.

Rinse and let air dry.

* Check the fit of each piece before

cementing in place.

* Use only cement for polystyrene plastic.

* Scrape plating and paint from areas

to be cemented.

* Allow paint to dry thoroughly before

handling parts.

* Any unused parts may be discarded.

DECAL APPLICATION INSTRUCTIONS

1. Cut desired decal from sheet.

2. Dip decal in water for a few seconds.

3. Place wet decal on paper towel.

4. Wait until decal is movable on paper backing.

5. Place decal in position on model, face up and

slide backing away.

6. Press out air bubbles with a soft damp cloth.

7. Milkiness that may appear is for better decal

adhesion and will dry clear. Wipe away any

excess adhesive.

8. Do not touch decal until fully dry.

9. Allow the decals 48 hours to dry before

applying clear coat.

NOTE: Decals are compatible with

setting solutions or solvents.

READ THIS BEFORE YOU BEGIN

LIRE CE QUI SUIT AVANT DE COMMENCER

* Etudier les schémas de montage.

* Chaque pièce en plastique est identifiée par un numéro.

* Sur les schémas de montage, certaines pièces sont

marquées d'une étoile (

★

) pour indiquer qu'elles sont en

plastique chromé.

* Pour une meilleure prise de la peinture et des autocollants,

laver les pièces en plastique avec une solution détergente

peu concentrée. Les rincer et les laisser sécher à l'air.

* Vérifier que chaque pièce s'ajuste bien avant

de la coller en place.

* N'utiliser que de la colle pour polystyrène.

* Gratter les parties à coller pour enlever le chrome et la peinture.

* Laisser la peinture bien sécher avant de manipuler les pièces.

* Toute pièce inutilisée peut être jetée.

DIRECTIVES D'APPLICATION DES AUTOCOLLANTS

1. Découper l'autocollant désiré de la feuille.

2. Tremper l'autocollant dans de l'eau pendant quelques secondes.

3. Placer l'autocollant mouillé sur une serviette en papier.

4. Attendez que l'autocollant puisse être déplacé sur son support

en papier.

5. Mettre l'autocollant en position sur le modèle face sur

le dessus et faire glisser le support pour l'enlever.

6. Appuyer avec un chiffon doux humide pour éliminer les bulles d'air.

7. La substance laiteuse qui peut apparaître est destinée à

améliorer l'adhésion de l'autocollant et devient incolore au

séchage. Essuyer pour enlever tout excédent d'adhésif.

8. Ne pas toucher l'autocollant tant qu'il n'est pas bien sec.

9. Laisser l'autocollant sécher pendant 48 heures avant

d'appliquer une couche transparente.

REMARQUE: Les autocollants sont compatibles avec

les solutions de fixage ou les solvants.