19

31-1000600 Rev. 0

Installation Instructions - Dual Integrated Installation

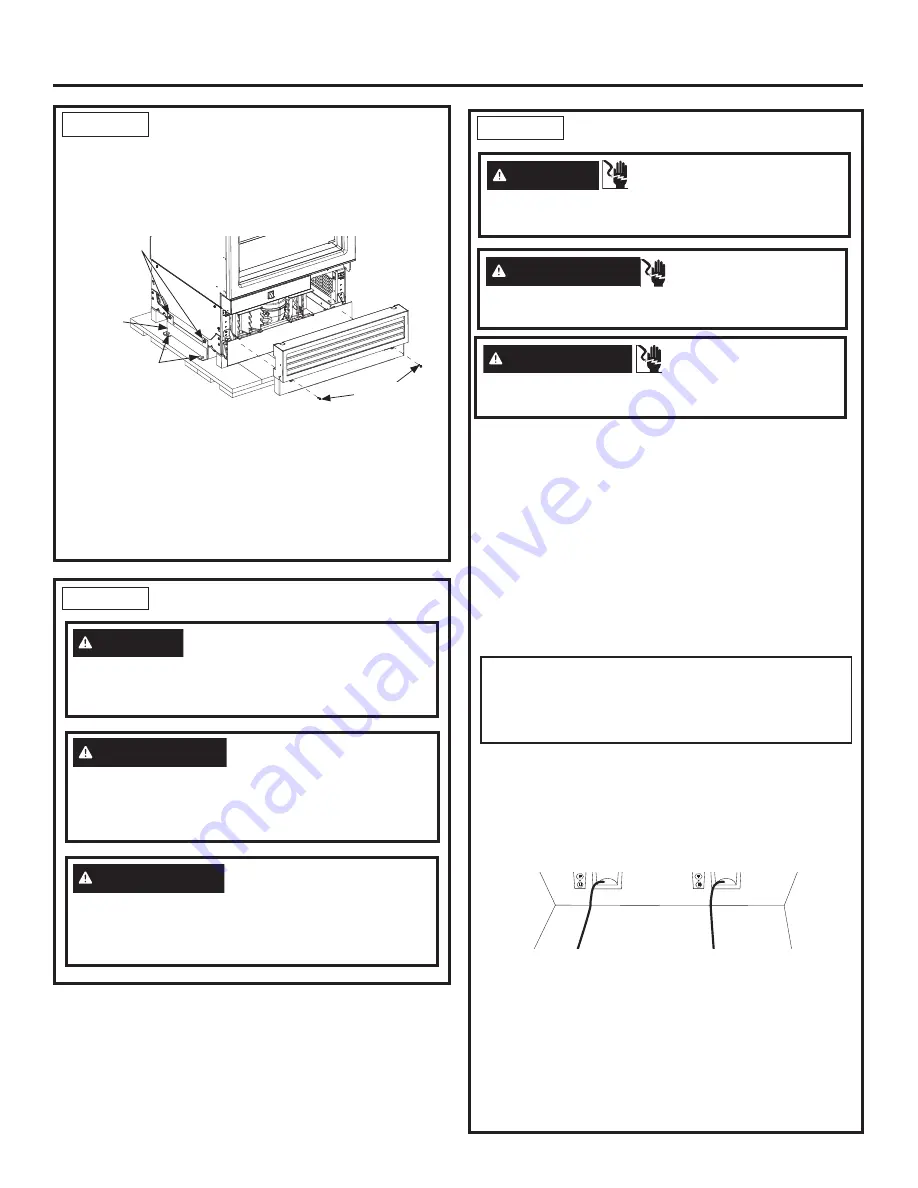

STEP 1 REMOVE PACKAGING

Ŷ

Remove front access cover from unit by removing two 1/4”

hex head screws. (Some models have access cover in a

box on the left side of the cabinet.) Place the cover and

screws to the side for future installation

.

Ŷ

Remove three 3/8” drive screws and two 7/16” drive

screws from each side of the unit to release it from the

shipping skid. Tip the unit from the side enough to remove

the shipping material from under the unit, but above the

shipping skid (both sides)

Ŷ

CAREFULLY roll the unit off the back side of the shipping

skid.

Ŷ

Handle from side only with a hand truck.

Shipping

Bracket

7/16” Drive

Screws

3/8” Drive

Screws

1/4” Hex Head

Screws

STEP 2 INSTALL WATER LINE

STEP 2 INSTALL WATER LINE

Shut off the main water supply.

Turn on the nearest faucet long enough to clear the line of

water.

Ŷ

Install a shut-off valve between the water valve and cold

water pipe in a basement or cabinet.

The shut-off valve

should be located where it will be easily accessible.

Ŷ

Turn on the main water supply and flush debris. Run about

a quart of water through the tubing into a bucket. Shut off

water supply at the shut-off valve.

NOTE:

Saddle type shut-off valves are included in many

water supply kits. Before purchasing, make sure a saddle

type valve complies with your local plumbing codes.

NOTE:

Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle

valves are illegal and use is not permitted in

Massachusetts. Consult with your licensed plumber.

Ŷ

Route 1/4” OD copper or SmartConnect

™

(WX08X10006)

plastic tubing between house cold water line and the water

connection location at the front of the unit.

SmartConnect

™

Refrigerator Tubing Kits are available.

One 8’ (2.4m) water line (WX08X10006) is needed for

each unit. The waterline(s) will be taped to the floor using

masking tape after anti-tip bracket installation.

Ŷ

Tubing should be long enough to extend to the front of the

unit. Allow enough tubing to accommodate bend leading

into the water line connection. Unit must be tipped on its

side to route waterline underneath and to the front of the

appliance.

NOTE:

The only GE Appliances approved plastic tubing is

supplied in the SmartConnect

™

Refrigerator Tubing kits. Do

not use any other plastic water supply line because the line is

under pressure at all times. Other types of plastic may crack

or rupture with age and cause water damage to your home.

WARNING

Connect to potable water supply

only. A cold water supply is required for automatic

icemaker operation. The water pressure must be

between 40 and 120 psi (275-827 kilopascals).

WARNING

ELECTRIC SHOCK HAZARD

Attach tubing clamp using existing hole only. DO

NOT drill into the refrigerator.

AVERTISSEMENT

Raccordez l’appareil à une

alimentation d’eau potable seulement. Une alimentation

d’eau froide est requise pour faire fonctionner la machine à

glaçons et le pichet à remplissage automatique. La pression

d’eau doit se situer entre 40 et 120 psi. (275 à 827 kPa).

AVERTISSEMENT

RISQUE DE DÉCHARGE

ÉLECTRIQUE

Fixez le collier de serrage dans le trou présent seulement.

NE PERCEZ PAS dans le réfrigérateur.

ADVERTENCIA

Realice la conexión a un suministro

de agua potable únicamente. Se requiere un suministro de

agua fría para el funcionamiento de la máquina de hielos

automática y de la jarra de llenado automático. La presión del

agua deberá estar entre 40 y 120 p.s.i. (275 – 827 kPa).

ADVERTENCIA

PELIGRO DE DESCARGA

ELÉCTRICA

Adhiera la abrazadera de la tubería usando el agujero

existente únicamente. NO perfore el refrigerador.