12

49-80152 Rev. 8

Installation Instructions

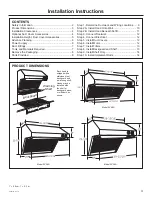

3

CONNECT DUCTWORK

■ Install ductwork, making connections in direction of

airflow as illustrated.

■ Secure joints in ductwork with sheetmetal screws.

■ Wrap all duct joints

with duct tape for an

airtight seal.

■ Use duct tape to

seal the flange

connection. Reach

inside the hood and

push the damper up

to be sure it moves

freely.

5

INSTALL DUCT COVERS

NOTE:

For easier handling, remove cardboard insert

after film is peeled off.

Remove protective film from duct covers. If more than

one duct cover is used, secure each piece together

with screws provided.

■ Place the duct cover(s) on top of the hood.

■ From inside the hood, secure the duct cover to the

top with the small Phillips head screws supplied

with the covers.

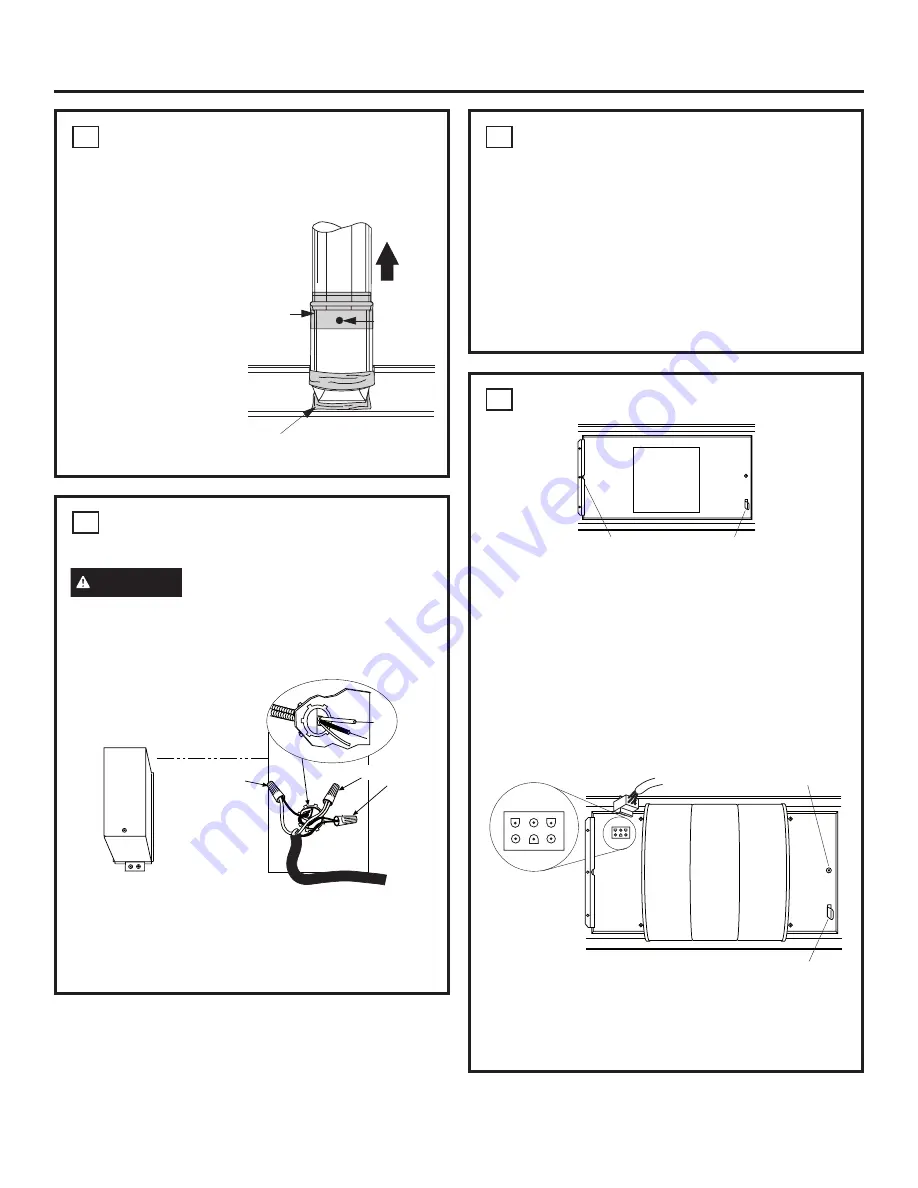

6

INSTALL MOTOR

■ From the inside of the hood, slip motor into the

attachment slot on the left.

■ Rotate motor upwards until it snaps into the spring

clip on the right.

■ Secure the motor to the hood with the machine

screw and lock washer. (Screw is marked with red

or blue paint.)

■ Plug connector into the motor.

IMPORTANT:

Connector ends are designed to mate

only one way. Match flat and round connectors as

shown.

4

CONNECT ELECTRICAL

Verify that power is turned off at the source.

WARNING

If house wiring is not 2-wire with

a ground wire, a ground must be provided by the

installer. When house wiring is aluminum, be sure

to use U.L. approved anti-oxidant compound and

aluminum-to-copper connectors.

■ Use wire nuts to connect incoming ground to green,

white to white and black to black.

■ Push wires into junction box and replace cover. Be

sure wires are not pinched.

Screw

Duct Tape

Over Seam

and Screw

Air Flow

Duct Tape

Over Transition

White

Ground

Black

Remove

Junction Box

Cover

Insert Power

Conduit Thru

Strain Relief

and Tighten

Use UL Listed

Wire Nuts

A

B

C

Top

Attachment

Screw

Spring

Clip

Spring

Clip

Outlet

Attachment

Slot

1” = 2.5 cm; 1’ = 0.3 m