30

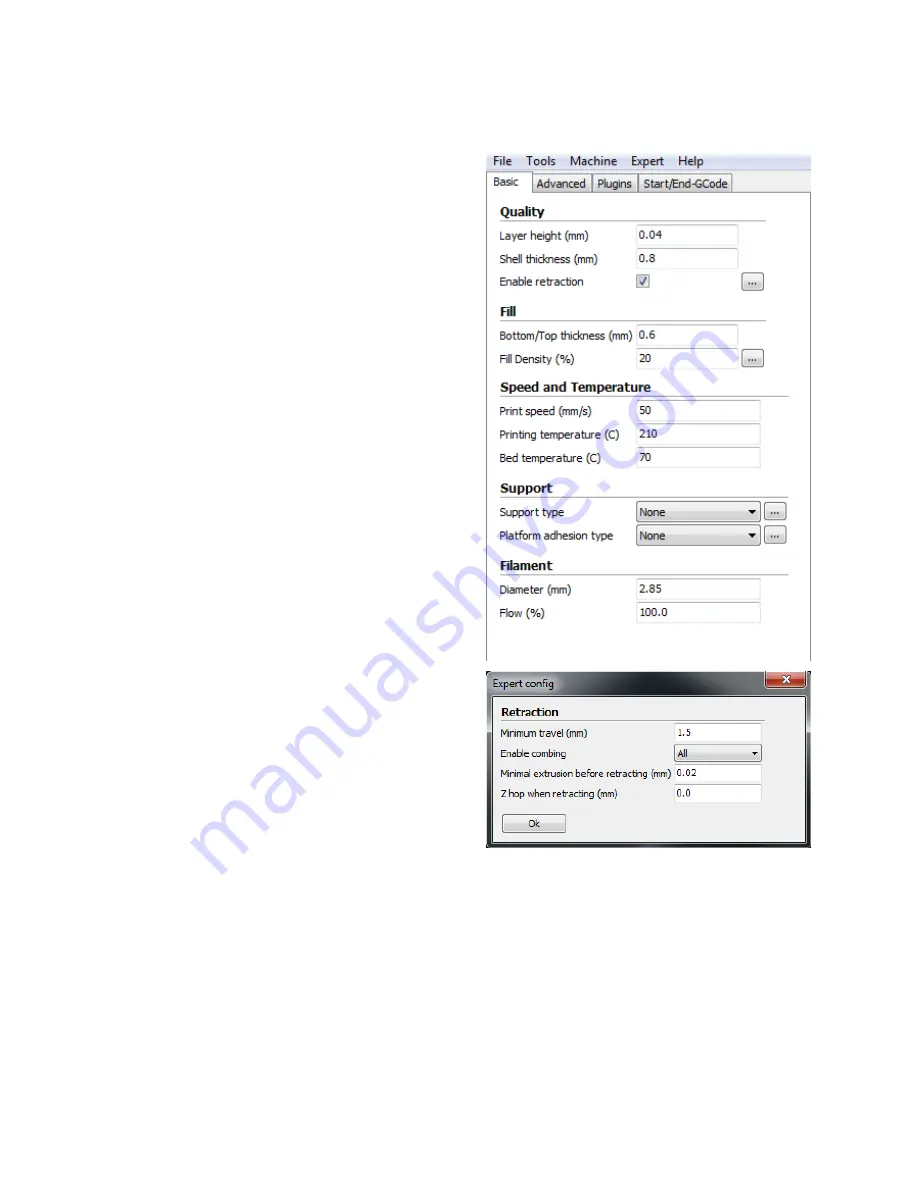

Basic Tab

Click the Basic tab to view the basic build

settings.

Layer Height - The Layer Height determines the

thickness of each printed layer. The smaller the

layer height, the more layers will be needed

and the more time will be required to print,

but the printed object will have smoother

curves and better detail. Larger layer heights

are better for bridging and overhangs.

Shell Thickness - Shell Thickness determines

the number of vertical walls that comprise the

outside of your model. We recommend that

you limit this to multiples of your nozzle width,

which is 0.5mm on this printer.

Enable Retraction - When this option is

enabled, the printer will retract filament from

the end of the nozzle during non-printing

moves/travels. We recommend that you keep

this option enabled for all filament types and

adjust the retraction length and speed for

different filament types. Click the ... button to

the right of the entry to adjust specific values.

Refer to the

Expert Settings section for

Retraction settings details.

Bottom/Top Thickness (mm) - This value determines the thickness of the bottom and top

layers of your printed object. Thicker layers can improve strength and print quality, and can

help with bridging. We recommend keeping this number to a multiple of your layer height.

Fill Density (%) - This value determines the amount of material printed inside the object. A

value of 0% will result in a completely hollow model, while a value of 100% results in a

completely solid object. We have found that a value of 20% to 40% is good for most prints.