6

Auto-Leveling

Before your first print, and anytime you remove the build plate,

you’ll want to run an auto-level to ensure that your parts adhere

well to the glass. Follow the procedure below to run an auto-level

and calibrate the Z-offset of your machine.

Adjusting the Z-Offset

The Z-offset is the distance between the glass build plate and

the nozzle. The auto-level process ensures that this distance is

consistent across the entire surface of the build plate, but the

distance itself must be manually calibrated. You can do this easily

using a piece of clean, flat copy paper, which are usually about

100 microns thick.

1. Ensure that the hotend is at room temperature.

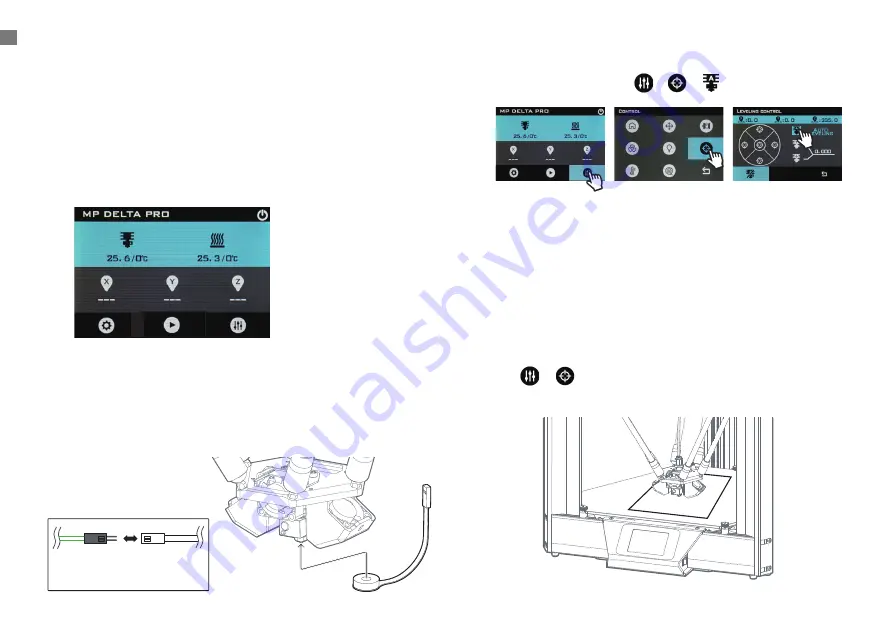

1. Tap

>

2. Place the piece of copy paper on the build plate.

PREPARING TO PRINT

2. Connect the auto-level sensor to the green wire from the

cable harness, and affix the the sensor’s foam ring to the

nozzle.

NOTE: Use the minimum amount of force required

to affix the sensor to the nozzle. If the nozzle is touching

the plastic membrane, it may prematurely trigger the

switch.

3. On the LCD screen, tap

>

>

Auto Leveling

4. Once the process is complete, remove the auto-level sensor.

Green Wire

from Effector

Wire Harness

Auto-level

Sensor Wire

Summary of Contents for Delta Pro

Page 1: ...Monoprice Delta Pro 3D Printer User s Manual ...

Page 15: ......