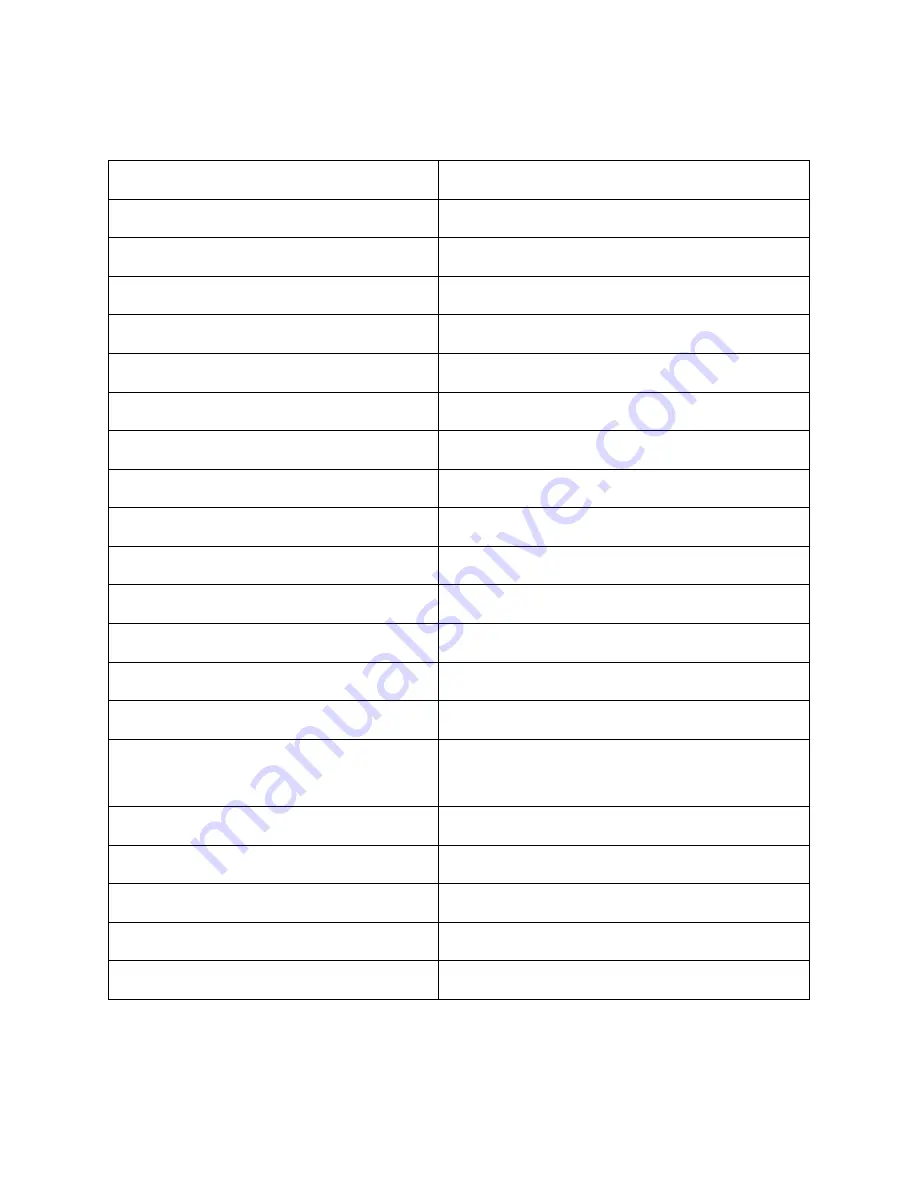

53

SPECIFICATIONS

Model

30527

Printer Name

MP Guider II

Number of Extruders

1

Print Technology

Fused Filament Fabrication (FFF)

Screen Type

5.0" color IPS touch screen

Build Area

280 x 250 x 300 mm

Layer Resolution

0.05 - 0.4 mm

Build Accuracy

±0.2mm

Positioning Accuracy

XY Axis: 0.011mm, Z Axis: 0.0025mm

Filament Diameter

1.75mm ±0.07mm

Nozzle Diameter

0.4mm

Build Speed

10~200 mm/sec

Software

MP FlashPrint

Supported Input Formats

3MF, .STL, .OBJ, .FPP, .BMP, .PNG, .JPG, .JPEG

Supported Output Formats

.G, .GX

Supported Operating Systems

Windows® XP and later (32-bit and 64-bit),

Mac® OS X®, Linux®

Input Power

100 ~ 240 VAC, 50/60 Hz

Power Consumption

500 watts

Connectivity

USB cable, USB stick, Wi-Fi®

Dimensions

19.3" x 21.7" x 22.0" (490 x 550 x 560 mm)

Weight

66.1 lbs. (30.0 kg)