© 2011 Monte Carlo Fan Company

2/2/2012

3

Insert downrod into motor yoke.

Next, insert clevis pin through yoke

and downrod and secure with cotter

pin. (see inset)

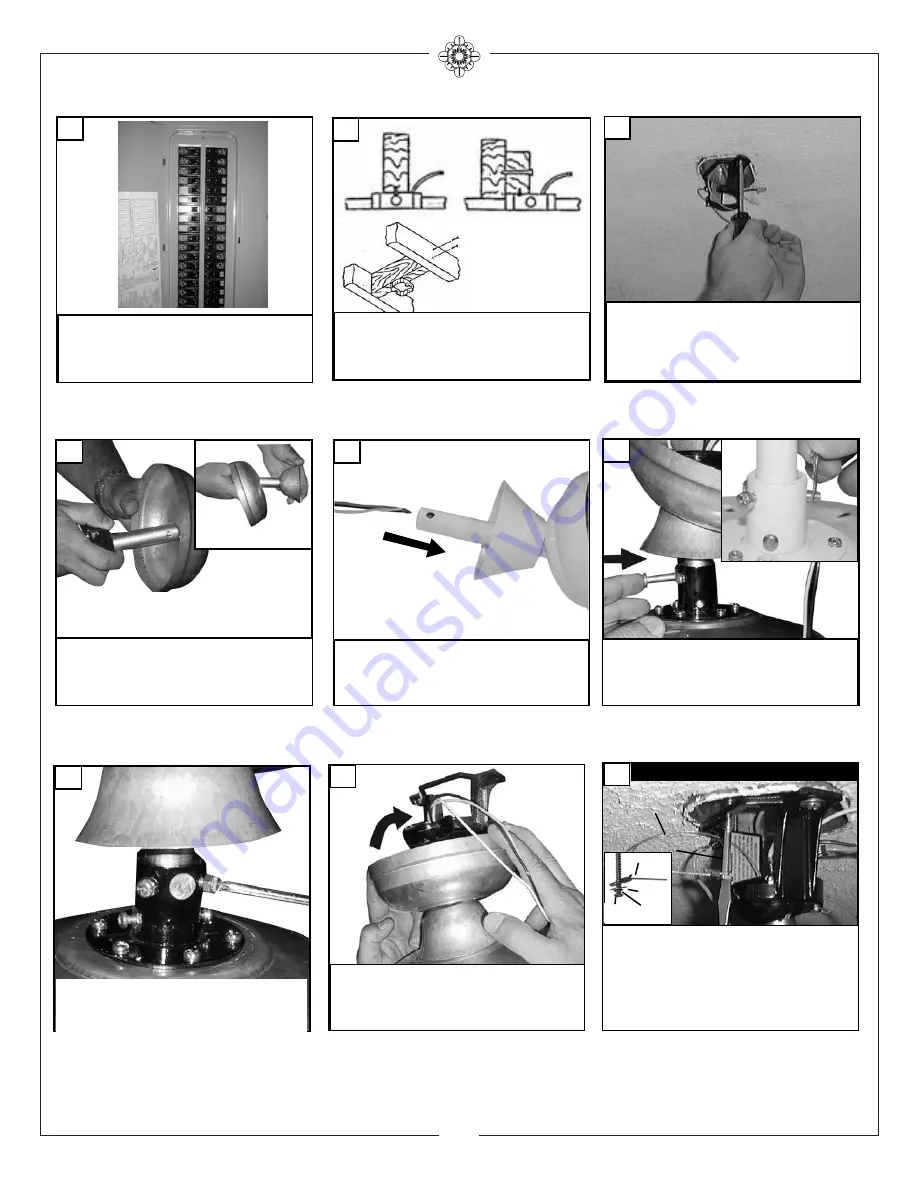

Before you begin installing the fan, Switch power off

at Service panel and lock service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

Install canopy and yoke cover over

the downrod.

1

4

6

Thread wire through downrod with

canopy and yoke cover assembled.

5

Before installing this fan make sure the outlet

box is properly installed to the house structure.

To reduce the risk of fire, electric shock, or per-

sonal injury, mount to outlet box or supporting

system acceptable for fan support.

(Mounting must support at least 35 lbs.)

Install the Mountiing Bracket to the

Outlet box.

Use only the screws

provided with the outlet box.

3

2

Carefully lift fan assembly onto mounting

bracket. Rotate fan so that the notch on the

ball engages the ridge in the mounting bracket.

This will allow hands-free wiring.

8

7

Tighten both yoke set screws to fur-

ther secure downrod.

For Canadian installation and for USA fan and

light kit combinations over 35 lbs, in both flush

and downrod mode the safety cable must be

installed into the house structure beams using

the 3” lag screws,washers, and lock washers.

provided. Make sure that when the safety cable

is fully extended the leadwires are longer than

the cable and no stress is placed on the lead-

wires.

9

Safety cable installation

Safety Cable

Lag Screw

safety

cable

3” lag

screw

lock

washer

washer

Summary of Contents for 5GP60XX Series

Page 7: ......