XG0222

51

Appendix

MONTIGO RESIDENTIAL WARRANTY PROGRAM

Canadian Heating Products Inc. and/or Montigo DelRay Corp

(collectively referred to herein as "The Companies"), warrants the

Montigo gas appliance (referred to herein as 'the appliance') to

be free from defects in materials and workmanship at the time

of manufacture. The gas appliance and related components are

further subject to the terms and conditions set forth below.

This warranty covers the following Montigo product series:

Distinction, H, I, L, Linear P and PL, R and Mahana

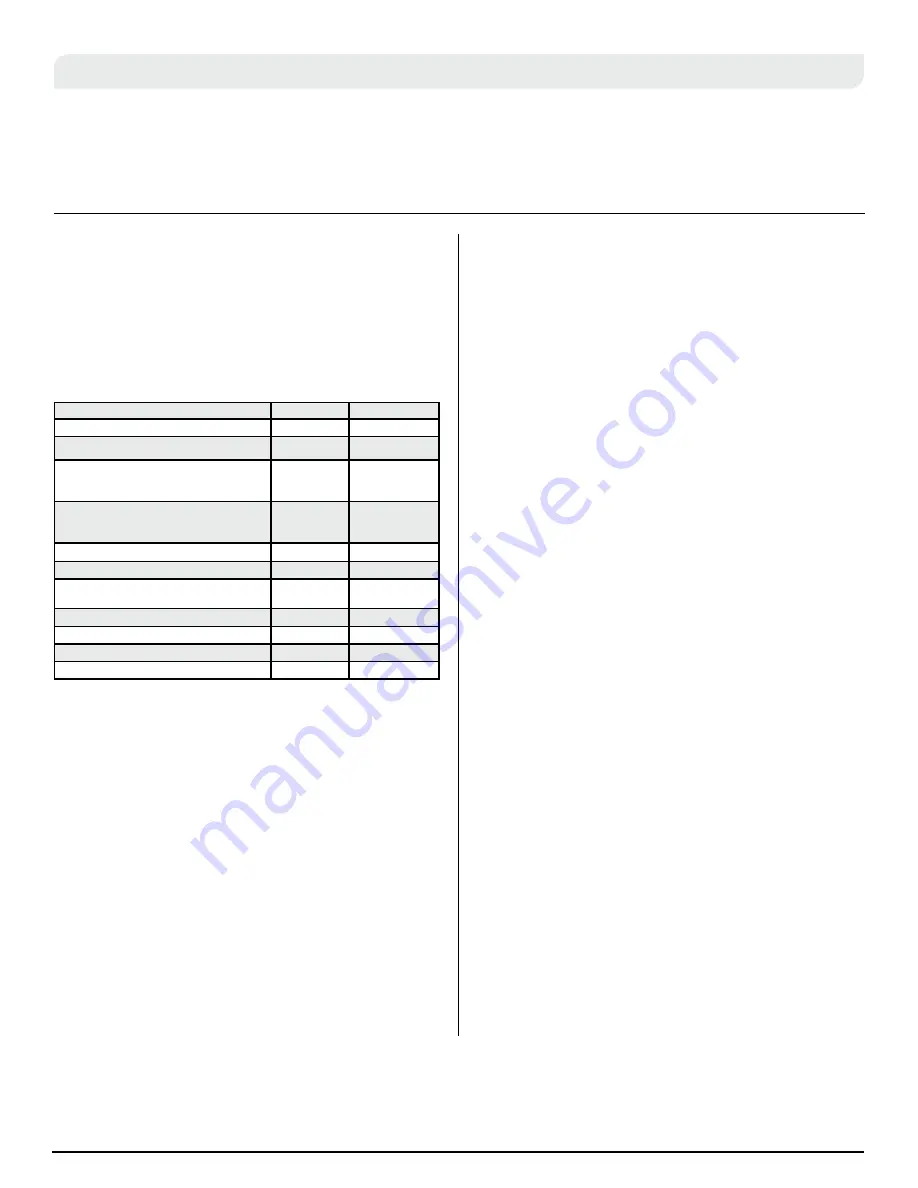

Component

Coverage Period

Labor Coverage

Firebox, heat exchanger

15 years

1 year

Main burner

15 years

1 year

Gas control valve and related control components

(pilot assembly, spark electrode flame sensors,

thermopile)

1 year

1 year

Electrical components (internal blowers, ignition

control module, wiring, switches, remote control

systems, blower control module, accent bulbs)

1 year

1 year

Firebox media (logset, glass beads, river rocks)

1 year

1 year

Glass (thermal breakage)

1 year

1 year

Plated, painted finishes (including interior reflective

glass)

1 year

1 year

Refractory lining

1 year

1 year

Mesh/Glass safety barriers

1 year

1 year

Power Vent Control box

1 year

1 year

Montigo Venting (excluding terminations)

15 years

1 year

QUALIFICATIONS TO THE WARRANTY

This Warranty only covers gas appliances installed in the United

States or Canada.

To receive the benefits of this warranty, the appliance must

be purchased, installed and serviced annually by a dealer

authorized by the Companies for the warranty to be valid.

The gas appliance must be installed by a licensed professional

in accordance with The Companies' installation instructions

and local building codes. The warranty on the appliance covers

only components manufactured by The Companies. The use of

components manufactured or supplied by other manufactures

and used in conjunction with the appliance could create serious

safety hazards, may result in the denial of certification by

recognized national safety agencies and could violate local

building codes. Such use may untimely void this warranty. This

warranty does not cover any damages occurring from the

use of any components not manufactured or supplied by The

Companies.

The appliance must be subjected to normal use. The appliance

is designed to burn natural gas (NG) or liquefied petroleum (LP)

only. Burning conventional fireplace fuels such as wood, coal or

any other solid fuel will cause damage to the appliance, produce

excessive temperatures will result in a fire hazard and void all

warranties. This warranty is transferable. The appliance must

remain in its original place of installation to be valid.

If the components of the appliance covered by this warranty

are found to be defective within the time frame stated (see The

Companies investigation of claims), the companies will, at its

option, replace or repair defective components of the appliance

manufactured by the company at no charge and will also pay for

labor costs (in accordance with schedule) incurred in replacing

or repairing components. If repair or replacement is not

commercially practical, the companies will, at its sole discretion,

provide a current or most like unit, excluding the cost of labor

unless the labor is covered by the terms of the warranty.

This warranty covers only parts and labor as provided above.

In no case shall the companies be responsible for materials,

components or construction. All replacement or repair

components will be shipped F.O.B. from the nearest Company

factory.

LIMITATION ON LIABILITY

It is agreed and understood that The Companies sole obligation,

and purchaser's exclusive remedy under this warranty, under

any other warranty, expressed or implied, or in contract, tort or

otherwise, shall be limited to repair or replacement as specified

above. The opinion of The Companies with respect to these

matters shall be final.

In no event shall The Companies be responsible for any

incidental or consequential damages caused by (but not limited

to) improper installation, installation by an unqualified or

unauthorized installer, accident, lack of regular maintenance,

user error, abuse, misuse, Acts of God, power surges, floods,

natural disasters, force majeure, defects in its appliance whether

such damage occurs or is discovered before or after replacement

or repair, and whether or not such damage is caused by The

Companies negligence. Some jurisdictions do not allow the

exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you. The

duration of any implied warranty with respect to the appliance

is limited to the duration of the foregoing warranty. Some

jurisdictions do not allow limitations on how long an implied

warranty lasts, so the above limitation or exclusion may not

apply to you.

Appendix B: Warranty