Page 7

EDVWSPV Horizontal Power Vent System

Part No. XG1303 - 120110

Installation

Figure 6.

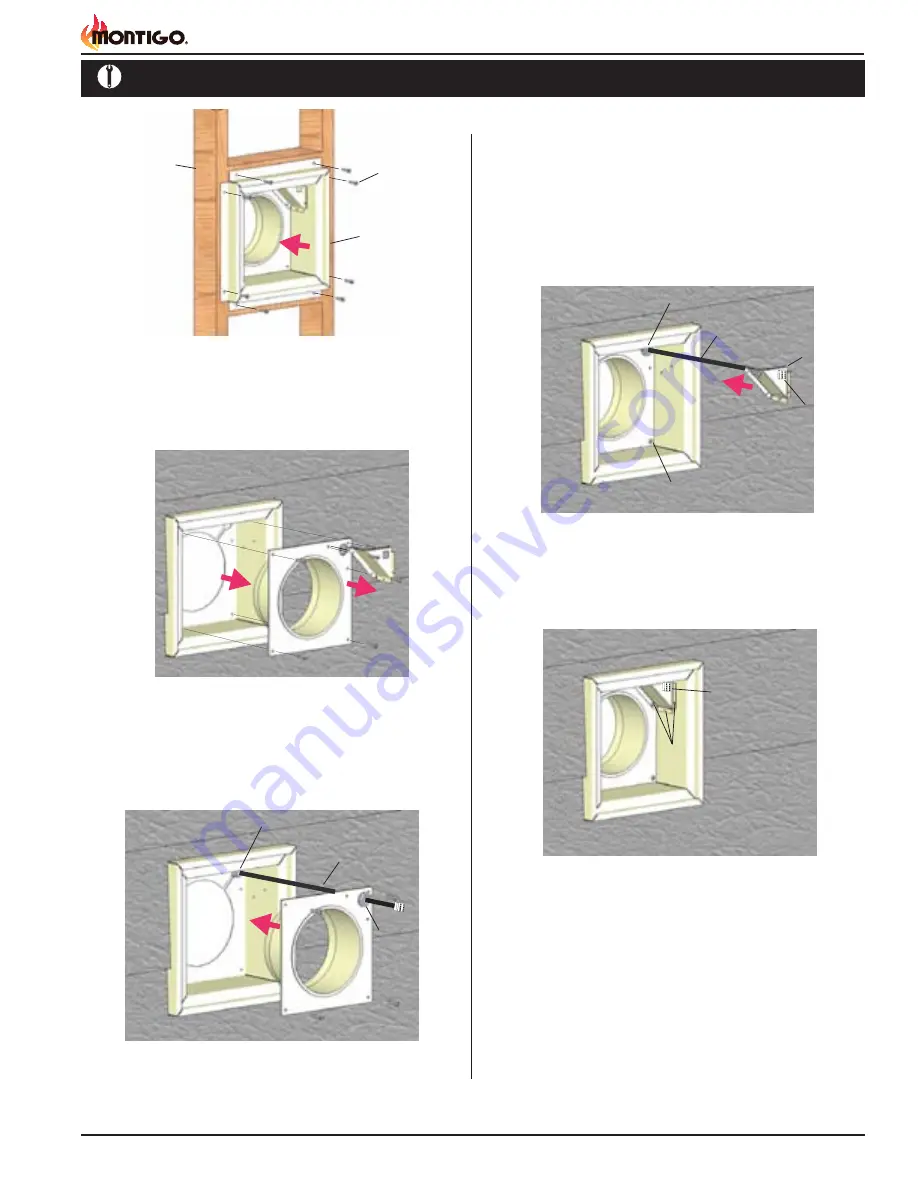

Installation of Rough-in Kit

Figure 7.

Installation of Power Vent Conduit

Step 3.

Next, remove the bottom collar and conduit mounting frame as

shown

Figure 6

.

(Place removed hardware in a handy location

for re-assembly).

Figure 5.

Orientation, Placing the Power Vent Inner Box

Framing

Rough-in Frame

Fasteners

Power Vent Conduit

Strain Relief

Nut

Step 4.

Insert the conduit from the Power Vent Module into the rough-in

frame through the

two top right

entry holes. Remove the nut from

the supplied strain relief and place as shown,

Figure 7

.

Strain Relief

Figure 7.

(Installing Conduit connector & conduit mounting frame)

Figure 8.

(Assembled Rough-in Kit)

Step 7.

Fasten Conduit mounting frame into place using existing hard-

ware,

(6-pcs). (Coil conduit in behind cover.)

Step 8.

Install the Power Vent Power / communication harness. Hold the

Power Vent in close proximity of the assembled Rough-in Kit,

and plug in the Power Vent communication / Power Cord.

(Note

the direction and orientation of the pins inside the Power Vent

connector, snap together). (Figure 9)

.

Power Vent Conduit

Strain Relief & tightened nut

Power Vent

Connector

Conduit

mounting

frame

Step 5.

Securely fasten bottom Collar pan into the Rough-in frame using

the existing hardware, (4-pcs). Tighten Strain Relief nut onto

Strain relief.

Step 6.

Pull Power Vent Connector,

(from behind)

half-way through

supplied hole in conduit mounting frame, and snap into place,

(notches in two plastic wing clips.

Orientation not critical).

Tightened hardware,

6-pcs.

Installed Power

Vent Connector

Tightened hardware,

4-pcs.