XG0302C

Page 1

EP8-5 Modular Series Fireplace

Maintenance

General

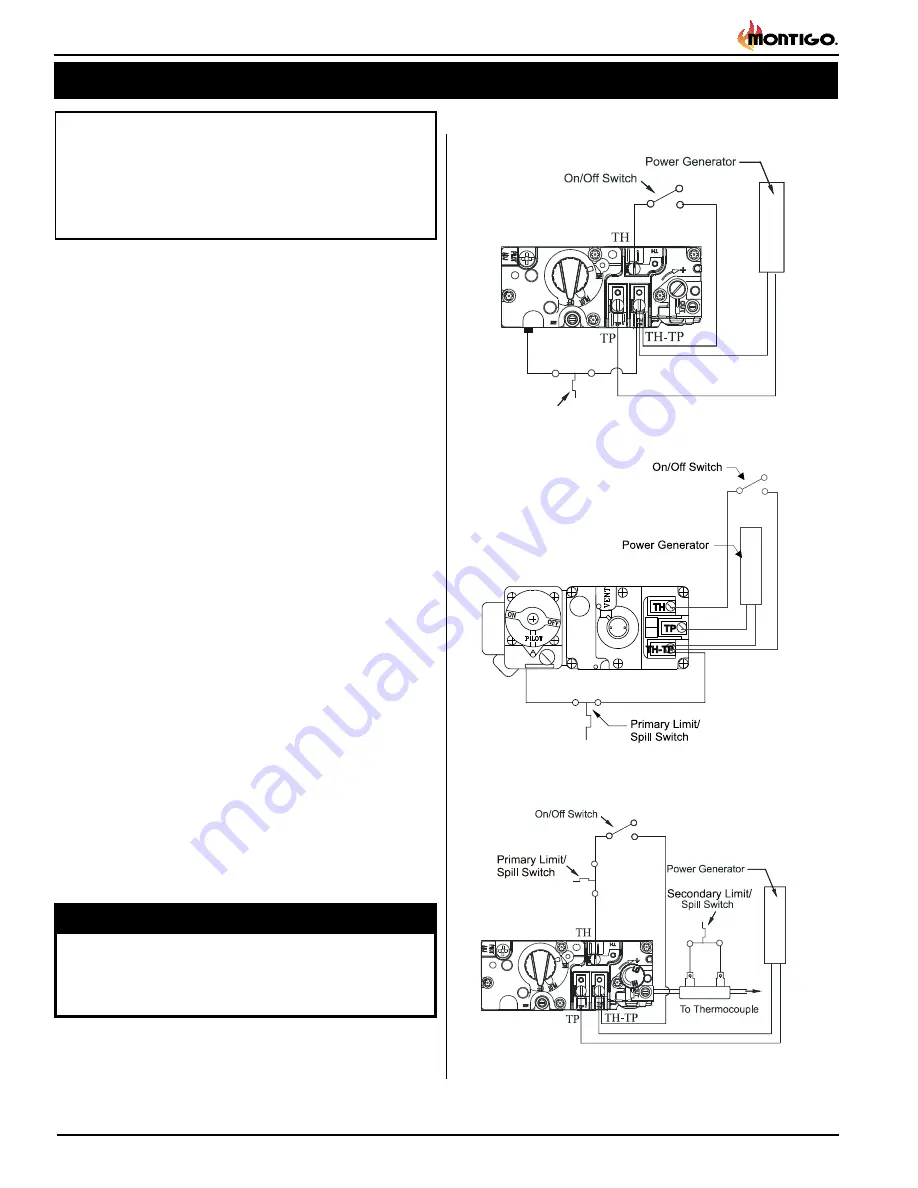

Have the fireplace installation inspected yearly, including a visual

check of the vent system, the burner and the pilot flame. For your

convenience a 1/8" manifold pressure tap is supplied on the gas

valve for a test gauge connection. See Figure 24a, 24b, or 24c.

For

Natural Gas

this appliance requires a minimum inlet pressure

of 5.5" W.C. and a manifold pressure of 3.5" W.C.

For

Propane Gas

this appliance requires a minimum inlet pres-

sure of 11" W.C. and a manifold pressure of 10" W.C.

Always keep the fireplace area clear and free of combustible

materials, as well as gasoline and other flammable vapours and

liquids.

Do not use this appliance if any part has been under water. Imme-

diately call a qualified service technician to inspect the appliance

and to replace any part of the control system and any gas control

which has been under water.

CAUTION

Fireplace gas control must be in the “OFF” position and pilot

and main burners extinguished when cleaning appliance with

a vacuum.

Glass and logs can get very hot. Handle only when cool.

Cleaning

When the fireplace is first activated, there may be some smoking and

a visible film may be left on the glass doors. This is a normal condi

-

tion, and is the result of burning the protective coatings on new metal.

Glass must be cleaned periodically to remove any film (a normal

bi-product of combustion) which may be visible. Handle the door

carefully, and clean it with non-abrasive glass cleaners. One of

the most effective products is Kel Kem.

Silicone seals on inner door during initial firing will "off gas",

leaving a visual deposit of a white substance on combustion

chamber walls. This can easily be removed by following the steps

described above.

Use a vacuum cleaner or whisk broom to keep the control com-

partment, burner, and firebox free from dust and lint.

WARNING:

Do not attempt to clean glass when hot.

Do not clean glass with abrasive materials as any glass etch-

ing may cause premature glass failure.

Gas Control Valve

Figure 24b. Robertshaw gas valve used on the EP28-2LB or the

EP28-4LB.

Figure 24a. Honeywell gas valve used on the EP28-2LB or the

Figure 24a. Honeywell VS8510E gas valve used on the EP28-S2.

Spill Switch