39

Installation

XG0228 - 021419

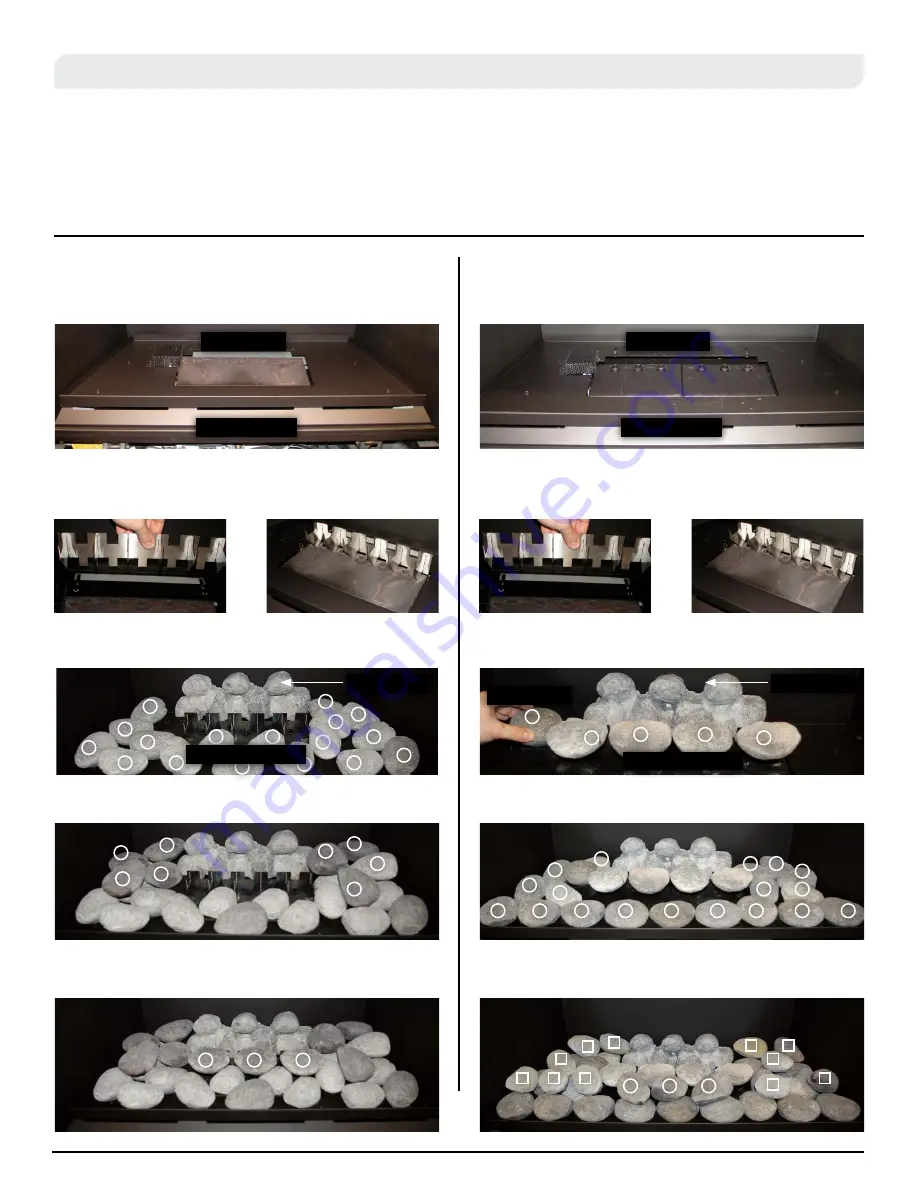

H38 Designer River Rocks Installation

H42 Designer River Rocks Installation

STEP 2:

Slide the rock guard locator tabs behind the Burner. The

rocks on the Rock Guard should line up between the air

inlets of the burner.

STEP 2:

Slide the rock guard locator tabs behind the Burner. The

rocks on the Rock Guard should line up between the air

inlets of the burner.

STEP 3:

Install Rear faux "A" ceramic 3 in1 Rock. Install Lower (17)

seventeen Faux Rock "B"

STEP 3:

Install Rear faux "A" ceramic 3 in1 Rock. Place the (4) four

centre faux rocks "B" on the riser spikes. faux rock C on Pilot cover.

STEP 4:

Install the Upper (8) eight Faux Rock "C" Note: place cut

surfaces of Rocks face down on lower Rocks.

STEP 4:

Place (18) eighteen faux rocks "D" as shown below.

STEP 5:

Next step, install the Front (3) three Center Front Faux

Rocks "D"

STEP 5:

Place three faux rocks "E" (shown circled). Place eleven

faux rocks "F" (shown as squares)

STEP 1:

Install the new Rock Tray and front cover. Make sure the

tray is not sitting on top of the pilot.

STEP 1:

Install the new Rock Tray and front cover. Make sure the

tray is not sitting on top of the pilot.

FRONT COVER

FRONT COVER

ROCK TRAY

ROCK TRAY

FAUX ROCK A

FAUX ROCK A

FAUX ROCK C

Figure 26.

H38DF*'s Fireplace Base.

Figure 27.

H42DF*'s Fireplace Base.

Figure 26.b

Figure 27.b

Figure 26.c

Figure 27.c

Figure 26.d

Figure 27.d

FAUX ROCKS B

FAUX ROCKS B