Page 16

H52-DF Gas Fireplace

Part No. XG0650

Maintenance

WARNING:

Do not attempt to clean glass when hot.

Do not clean glass with abrasive materials as any glass

etching may cause premature glass failure.

General

■

Have the fireplace and installation inspected yearly

. The inspection

must include, but is not limited to, the following:

•

A visual check of the entire vent system and termination.

•

An inspection of the explosion relief flappers and the door

gasketing to ensure a proper seal.

•

An inspection of the burner, venturi, and primary air openings.

•

An inspection of the gas valve, gas components, and pilot flame.

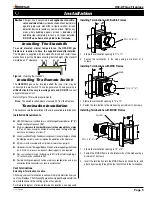

For your convenience a 1/8" manifold pressure tap is supplied

on the gas valve for a test gauge connection. See Figure 32.

•

Ensure proper log placement as per this manual.

•

Inspection of all optional equipment; fans, thermostats, etc.

■

For

Natural Gas

this appliance requires a minimum inlet pressure

of 5.5" W.C. and a manifold pressure of 3.5" W.C.

■

For

Propane Gas

this appliance requires a minimum inlet pressure

of 11" W.C. and a manifold pressure of 10" W.C.

■

Always keep the fireplace area clear and free of combustible materials,

as well as gasoline and other flammable vapors and liquids.

■

Do not use this appliance if

any part has been under water

. Immediately

call a qualified service technician to inspect the appliance and to

replace any part of the control system and any gas control which

has been under water.

Cleaning

When the fireplace is first activated, there may be some smoking and

a visible film may be left on the glass. This is a normal condition, and is

the result of burning of protective coatings on new metal.

■

Glass must be cleaned periodically to remove any film (which is

a normal by-product of combustion) which may be visible. Film

can easily be removed by removing the door, as shown on page

15. Handle the door carefully, and clean it with non-abrasive glass

cleaners. One of the most effective products is Kel Kem.

■

Silicone seals on inner door during initial firing will "off gas", leaving

a visual deposit of a white substance on combustion chamber walls.

This can easily be removed using normal household products.

■

Use a vacuum cleaner or whisk broom to keep the control

compartment, burner, and firebox free from dust and lint.

■

Logs may be cleaned periodically with a vacuum to remove soot or

other contaminates.

Troubleshooting

If your fireplace still does not operate correctly, consult your dealer or

the manufacturer.

All service and repairs should be performed by a qualified

agency.

All spare parts, optional fans, and optional trim finishes are available

from your local dealer or the manufacturer.

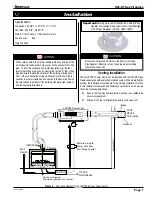

- Tu

rn Gas Supply Of

f

- Set thermostat to

call for heat

SV9500 / SV9600

is powered

(24V

AC nominal

)

HSI

Terminals

NOTE:

Before T

roubleshooting, Familiarize

Y

ourself With

The Startup

A

nd Checkout Procedure.

ST

AR

T

HONEYWEL

L

SV9500 /9600

Tr

oublshooting Sequence

INSE

T

NO

CHECK:

- Line voltage power

- Low voltage transformer

- Limit Controller

- Thermostat

- Wirin

g

-

Air proving switch on

combustion air blower system

-Vent damper (if used) is open

and end switch made

NO

NO

YES

NO

YES

Unplug Pilot Burner Cable,

Measure V

oltage at

SV9500/SV9600 HSI

T

erminals (24V

AC

Nominal, see INSET)

Replace

SV9500/

SV9600

Igniter warms up and

glows red.

YES

YES

NO

YES

NO

Pilot

Valve opens.

Replace Igniter /

Flame Rod Assembly

Replace SV9500/SV9600

NO

NO

YES

YES

Turn gas on.

Pilot Burner Lights?

Main Valve opens?

SYSTEM OK

Discard old Igniter /

Flame Rod Assembly

Measure

Vo

lume to

SV9500 / SV9600 Vo

ltage

must be at least 19.5 VA

C

Check

Transformer

Line

Vo

lt

Supply

Replace Igniter /

Flame Rod Assembly

Replace

SV9500 /

SV9600.

Save old

Igniter/ Flame

Rod Assembly

for service.

Replace Igniter / Flame

Rod Assembly and retain.

Restart troubleshooting

Sequence. Does main

valve open?