Page 1

Part No. XG0105B

ME34-DV-2 Homefire

Maintenance

Troubleshooting

If your fireplace still does not operate correctly, consult your dealer or

the manufacturer.

All service and repairs should be performed by a qualified

agency.

All spare parts, optional fans (see optional fan instruction guide), and

optional trim finishes are available from the manufacturer or your local

dealer.

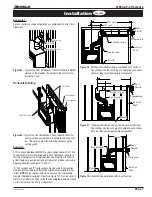

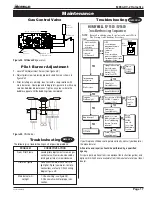

HONEYWELL SV 9500 /SV9600

Troubleshooting Sequence

NOTE:

Before Troubleshooting, Familiarize Yourself With

The Startup And Checkout Procedure.

· TurnGasSupplyoff

· Setthermostatto

call forheat

SV9500/SV9600

ispowered

(24VACnominal)

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

START

Igniterwarmsup

andglowsred.

PilotValveopens.

Turngason.

PilotBurnerlights?

MainValveopens?

SYSTEMOK

UnplugPilotBurnerCable,

MeasureVoltageat

SV9500/SV9600HSI

Terminals(24VAC

Nominal, SeeINSET)

ReplaceIgniter/

FlameRodAssembly.

ReplaceIgniter/

FlameRodAssembly.

ReplaceSV9500/SV9600

MeasureVoltagetoSV9500

/SV9600. Voltagemust

beatleast19.5VAC

DiscardoldIgniter/

FlameRodAssembly.

ReplaceIgniter/Flame

RodAssemblyandretain.

RestartTroubleshooting

Sequence. Doesmain

valveopen?

Replace

SV9500/

SV9600

Check

Transformer

LineVolt

Supply

Replace

SV9500/

SV9600.

Saveold

Igniter/Flame

RodAssembly

forservice.

INSET

HSI

Terminals

CHECK:

· Linevoltagepower

· Lowvoltage transformer

· LimitController

· Thermostat

· Wiring

· Airprovingswitchon

combustionairblowersystem

· Ventdamper(ifused) isopen

andendswitchmade

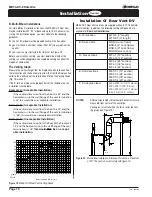

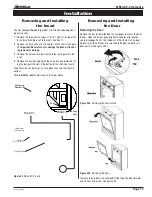

Gas Control Valve

Figure 28.

Sit Nova 820

gas valve

.

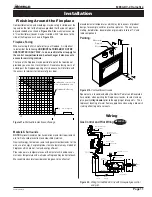

Pilot Burner Adjustment

1.

Locate Pilot Adjustment Screw.

(See figure 28.)

2.

Adjust pilot screw to provide properly sized flame as shown in

figure 29).

3.

After installing or servicing, leak test with a soap solution with

main burner on. Coat pipe and tubing joints, gasket etc. with soap

solution. Bubbles indicate leaks. Tighten any areas where the

bubbles appear until the bubbling stops completely.

ME34-DV-I-2

Figure 29.

Pilot Burner

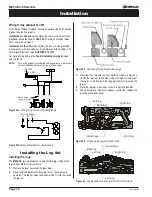

Troubleshooting

The following is a troubleshooting chart of possible problems:

PROBLEM

CORRECTIVE ACTION

Noisy Pilot Flame

Locate pilot adjustement screw on gas

control valve. Flame is decreased by

turning adjustment screw clockwise.

Pilot won’t ignite

Disconnect remote wires and try to

light pilot. If pilot now works, remote

connections are faulty. Check wiring

diagram

figure

28

.

Main burner will

1. Check wiring (

see figure 28

).

not light

2. Check wall switch for proper con-

nection.

ME34-DV-2

Manifold Pressure

Test Connection

Pilot Adjustment Screw

Inlet

Pressure

Power

Generator

Wall Switch