Page 5

HT34-PV Series Power Vent Gas Fireplace

Part No. XG0530 - 041510

Installation

Vent Installation

This section covers the installation of direct venting and terminations.

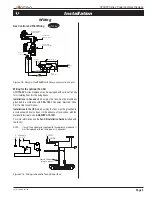

Installation Requirements

H

T34D-PV

Series fireplaces are certified for use with Montigo Standard

Series

(4" / 7")

venting components.

Minimum

clearance to combustible construction around the vent pipe

is 1"

on all sides, except on horizontal venting where the

top

of the pipe

must have a clearance of at least 2".

Use only

certified Montigo vent components.

(Use of other parts will void

the Montigo warranty, and may impede the operation of the fireplace.)

All joints must be secured with a minimum of two screws per joint

Vent terminations must not be recessed in walls or siding

Horizontal runs must be supported by a minimum of two supports per horizontal

run. A minimum of one screw on each side of support is also required

Flex vent sections may be stretched up to 50% of their total length (eg. a

24" section may be stretched to 36")

Solid vent sections may be cut less than half way from the female end

Venting components can be used in any combination of solid/rigid pipe or flex

pipe and in any orientation (Male connectors can face in any direction)

Vent Terminations

Selecting A Termination Location

Choosing your vent termination location will help to determine whether

you need to use a top vent or rear vent fireplace.

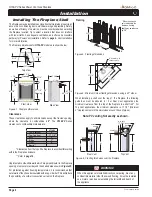

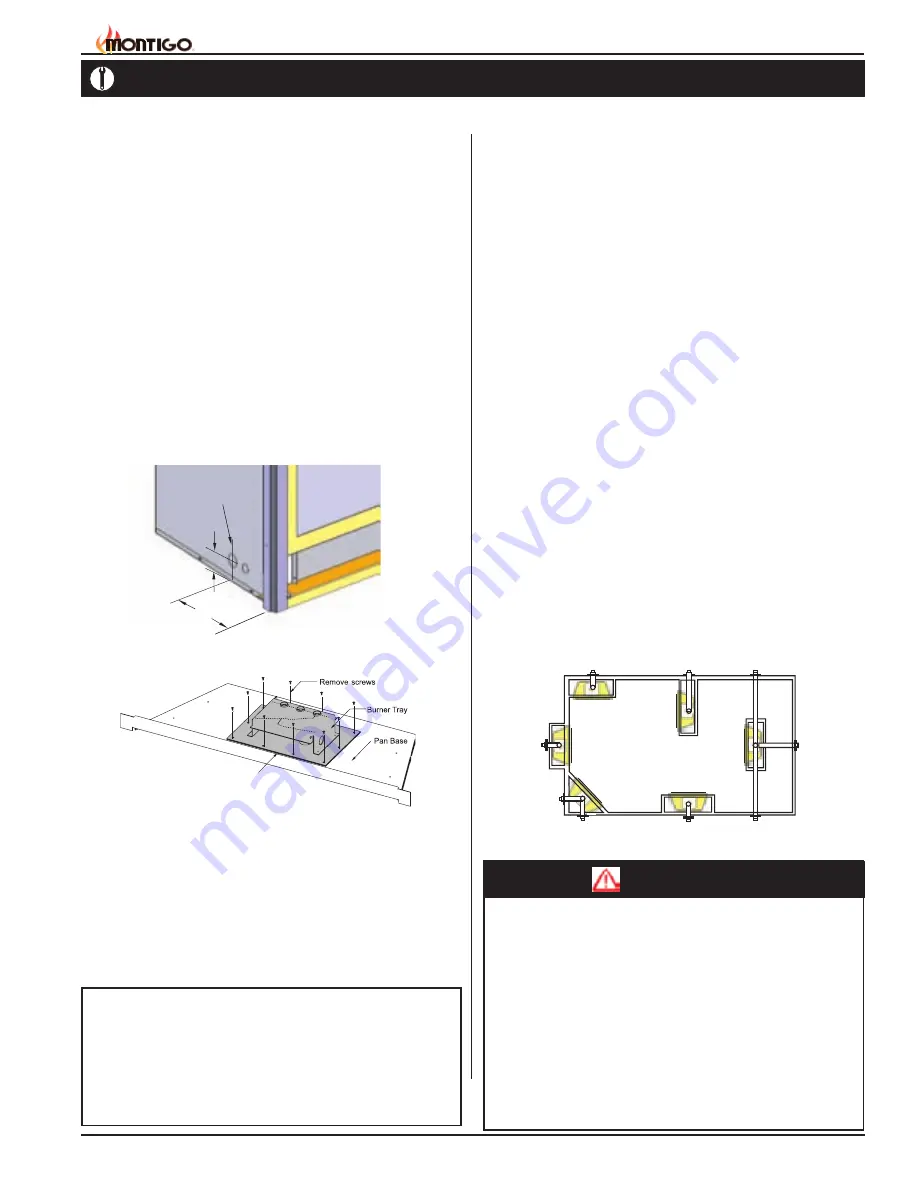

Figure 6a

, below,

shows typical fireplace locations and the venting options they provide.

For a more detailed diagram of allowed termination locations, see

Ap-

pendix A

.

Figure 6.

Fireplace locations and vent terminations.

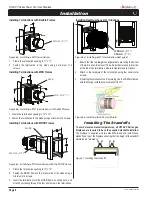

Installing The Gas Line

The gas line must be installed before finishing the

HT34-PV

Series

Fireplace.

Natural Gas

requires a minimum inlet gas supply pressure

of 5.5" W.C. & a manifold pressure of 3.5" W.C.

Propane Gas

requires a

minimum inlet gas supply pressure of 11" W.C. & a manifold pressure of

10" W.C. Provision must also be made for a 1/8" N.P.T. plugged tapping

and be accessible for test gauge connection immediately upstream of

the gas supply controls to the appliance. The fireplace gas connection

and the main operating gas valve is located behind the removable trim

at the bottom of the unit and need only be attached to the gas line with

an approved fitting, as required by the

applicable installation codes

.

To access the fireplace gas connection the main burner must be

removed as shown below in

figure 5b

.

• Only use gas shut-off valves approved for use by the state, province,

region, or governing body, in which the appliance is being installed, or

as required by the applicable installation codes.

• Flexible gas connectors must not exceed 3 feet in length, unless it is

allowable within applicable installation codes.

Note:

After gas line is connected,

each appliance connection,

valve and valve train

must be checked while under normal

operating pressure with either a liquid solution, or leak

detection device, to locate any source of leak. Tighten any

areas where bubbling appears or leak is detected until

bubbling stops completely or leak is no longer detected.

DO NOT use a flame of any kind to test for leaks.

Figure 5a.

Gas line access.

The appliance and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 psig (3.5 kPa).

The appliance must be isolated from the gas supply piping system by

closing its individual manual shut-off valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than

1/2 psig (3.5 kPa).

Burner Tray Gasket

Figure 5b.

Gas line access.

Gasline Acces

0.875 dia.

7

to center

2

Cautions:

Vent terminations can be very hot. If the termination is less than 7 feet

above a public walkway, it should be fitted with a certified Montigo

Heat Guard. (Part no. PTKOG).

Do not obstruct, or attempt to conceal the vent termination.

These actions will affect the operation of the fireplace, and may

be hazardous.

In heavy snow areas, take extra care to prevent snow buildup

from obstructing the vent termination.

Use Montigo Vinyl Heat Shield (Part no. VSS) when using on ap-

plications with vinyl siding to guard against possible damage.