Page 11

L-Series DF Gas Fireplace

Part No. XG0180

f i r e f e a t u r e

Installation

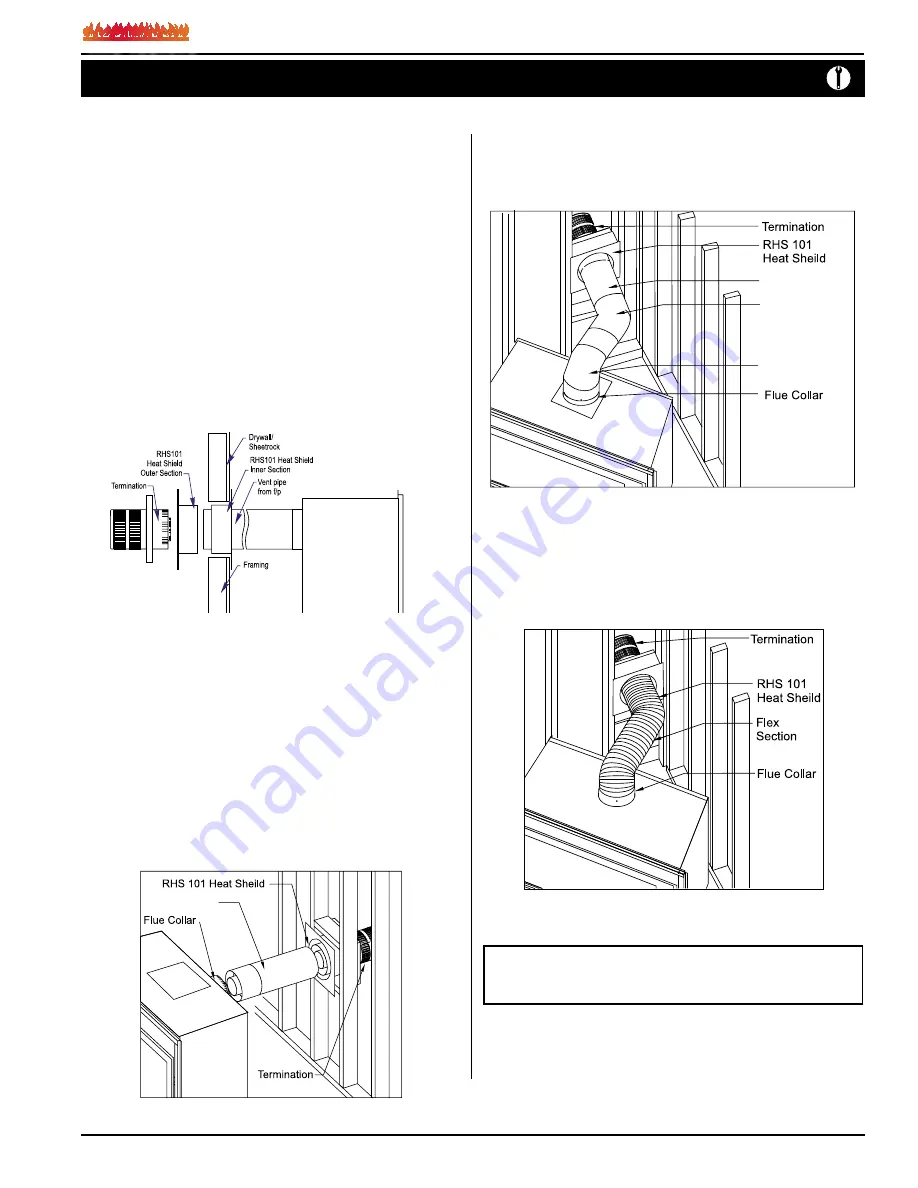

Important: Corner Installation is available only for

Top Vent Units.

Figure 20.

Corner installation.

Figure 21.

Flex installation.

(NG Models Only)

2. 45° Corner Installation.

Attach an PEL-90 (90° elbow) directly onto the flue collar, and attach

it to the PEL-45 (45° elbow). Cut the PXT-18 to suit and insert it into

the PEL-45. Slide the fireplace into position, and then connect it to

the exterior termination.

3. Corner Installation — 45° or less.

Use an PTO-3 termination and an PFL-1 or PFL-2 (12" or 24"

compressed length) and a frame, if appropriate.

Flex may be turned to

obtain desired degree of angle required but must not exceed 45°.

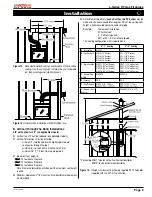

Figure 19a.

Extended installation.

PXT-12

PXT-18

PEL-45 Elbow

PEL-90 Elbow

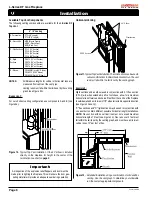

Rear Vent Venting Runs

The L-Series DF Rear Vent

has three possible installations which do

not require vertical lift, all of these installations require that you install

the RHS101 heat shield.

Heat Shield

The heat shield (RHS101) must be used on

all installations straight

through the wall

, at the point where the vent pipe connects to the

termination. With the heat shield, proper vent clearances can be

maintained.

The heat shield is not included with the fireplace.

To install the heat shield, slide one section over the vent pipe on the inside

of the wall opening, with the circular portion

inside the wall cavity

. Screw

the shield in place over the wall opening. Install the second section on

the outside of the wall opening sliding the circular portion into the wall

opening. Refer to Figure 19.

Figure 19.

Heat Shield. Install by sliding over the vent pipe where it

passes through combustible construction.

1. Straight Installation.

The height from the hearth to the center of the termination is 21

3/4". For straight installations use a 12" extension pipe (PXT-12)

with female/female connections. For shorter installations, cut the

PXT-12 to the desired length. Refer to figure 19a.

Ensure that the RHS101 heat shield is installed before attaching

the pipe to the termination.

Note:

For Rear Vent models, maximum horizontal run with no

vertical lift must never exceed 12".