Page 14

L-Series DF Gas Fireplace

Part No. XG0180

f i r e f e a t u r e

Installation

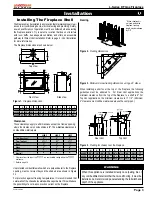

Finishing Around the Fireplace

Combustible mantels and mouldings may be safely installed over the

top and on the front of the fireplace provided that they do not project

beyond shaded area shown in

Figure 24

. Side wall clearances are 3".

Combustible surrounds may be installed with 3" clearance to the side

of the fireplace as shown in

Figure 25.

Fireplace Facing

When selecting the finish material for your fireplace, it is important to

remember the following:

If the surround of the fireplace is to be painted to match the room decor,

heat-resistant paint must be provided . Also, decorative facing must not

extend past the fireplace opening at all, because it will interfere with the

access to retainers for removal of glass door and access to the lower

compartment.

Mantels & Surrounds

NOTE:

National Canadian Gas Association mantel test requirements

are for fire hazard prevention to combustible materials.

New technology, to meet consumer and government demands for the

wise use of energy, has prompted us to manufacture many models of

fireplaces which are hot, fuel and energy efficient.

Please be aware; temperatures over the mantel will rise above normal

room temperature and walls above fireplace may be hot to touch.

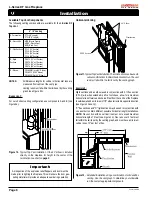

Warning:

When covering the upper metal portion of the fireplace, up to 6" (

as

shown, Fig.24 & Fig.25

) with a non-combustible material Please Note: The

decorative facing materials may be subject to temperatures in excess of

250° F. This should be considered when selecting facing materials.

We recommend careful consideration be given to the effects of elevated

mantel temperatures which may be in excess of product design, for

example: candles, plastic or pictures. This can cause melting, deformation,

discoloration or premature failure of T.V. and radio components.

Painting:

Special care is recommended by the Master Painters and Decorators

Association, when painting the fireplace surrounds, to select and apply

a quality Alkyd sealer

prior to the applying of latex paints. This is to

prevent leaching of water from evaporation and causing a brownish

staining effect to paint over coats.

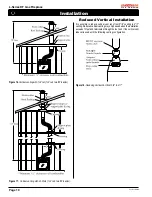

Figure 25.

Combustible surrounds.

Figure 24.

Combustible mantles and facings.

Horizontal Run (in)

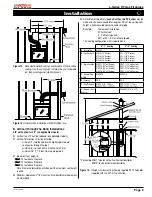

Figure 24a.

Combustible surround Shield, (three (3-pcs).

Side shield

(L42-DF only)

Side shield

(L42-DF only)

Surround Heat Shield

Included with the L42-DF Gas fireplace, is a heat shield fabricated from

galvanized steel. The kit comes with three (3) pieces as shown below.

This shield is to protect all adjacent combustible mantels and mouldings

from excessive heat radiated by the cabinet of the fireplace. This shield

must be installed as shown in

Figure 24a.

1). Top shield fastened as shown. Wide flange face up, shallow flange

toward inside of room, nailed or screwed flush with framing.

2). Side shield's fastened as shown

(Rear Vent Gas fireplace only)

.

Wide flanges face out, shallow flange toward inside of room, nailed or

screwed flush with framing.

Top shield

(L42-DF only)

Non-Combustible

Facing Material

Non-Combustible

Facing Material

Header

Drywall/

Sheetrock