Page 5

L-Series DF Gas Fireplace

Part No. XG0180

f i r e f e a t u r e

Installation

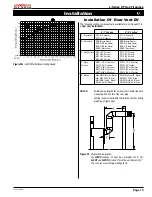

Installing Terminations with Built-In Frames

Installing Terminations with MSR Frames

12

12

1. Frame the termination opening to 12" x 12".

2. Fasten the termination to the studs using a minimum of 4 screws.

11

11

1. Frame the termination opening to 11" x 11".

2. Fasten the termination to the studs using a minimum of 4

screws.

Installing Terminations with MOSR Frames

12

12

12

MOSR

1. Frame the termination opening to 12" x 12".

2. Fasten the MOSR frame to the interior side of the studs using a

minimum of 4 screws.

3. Insert the termination into the MOSR frame as shown here, and

attach by screwing through the four pilot holes in the termination.

MSR

PTO-3F (5"/8")

PTO-3F (5"/8")

PTO-3F (5"/8")

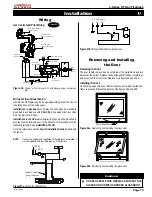

PTKOG

(5"/8")

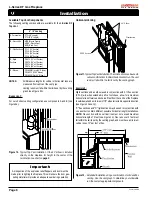

1. Ensure that the two

long

mounting brackets are facing the bottom

of the termination. (See inset). This will provide more heat protection

at the top of the termination, where temperatures are highest.

2. Attach to the faceplate of the termination using four sheet metal

screws.

Installing Heat Guards over Terminations

Installing The Remote Switch

The L-Series DF'

s gas valve, located behind the lower trim, may be

connected to a wall switch. The valve generates its own power on

a

millivolt circuit. Use only low voltage wire, and DO NOT connect

any external power to it.

Note:

The switch location must not exceed 30' from the fireplace.

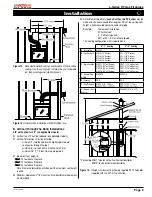

Installing The Standoffs

To avoid elevated mantel temperatures, all L-Series DF gas

fireplaces are required to have the supplied standoffs installed.

The fireplace is supplied with two standoffs. Bend and install these

standoffs on top of the fireplace ensuring that the height of the standoff

maintains a 6" clearance.

Figure 6b.

Installing the standoffs.

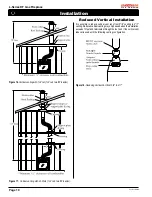

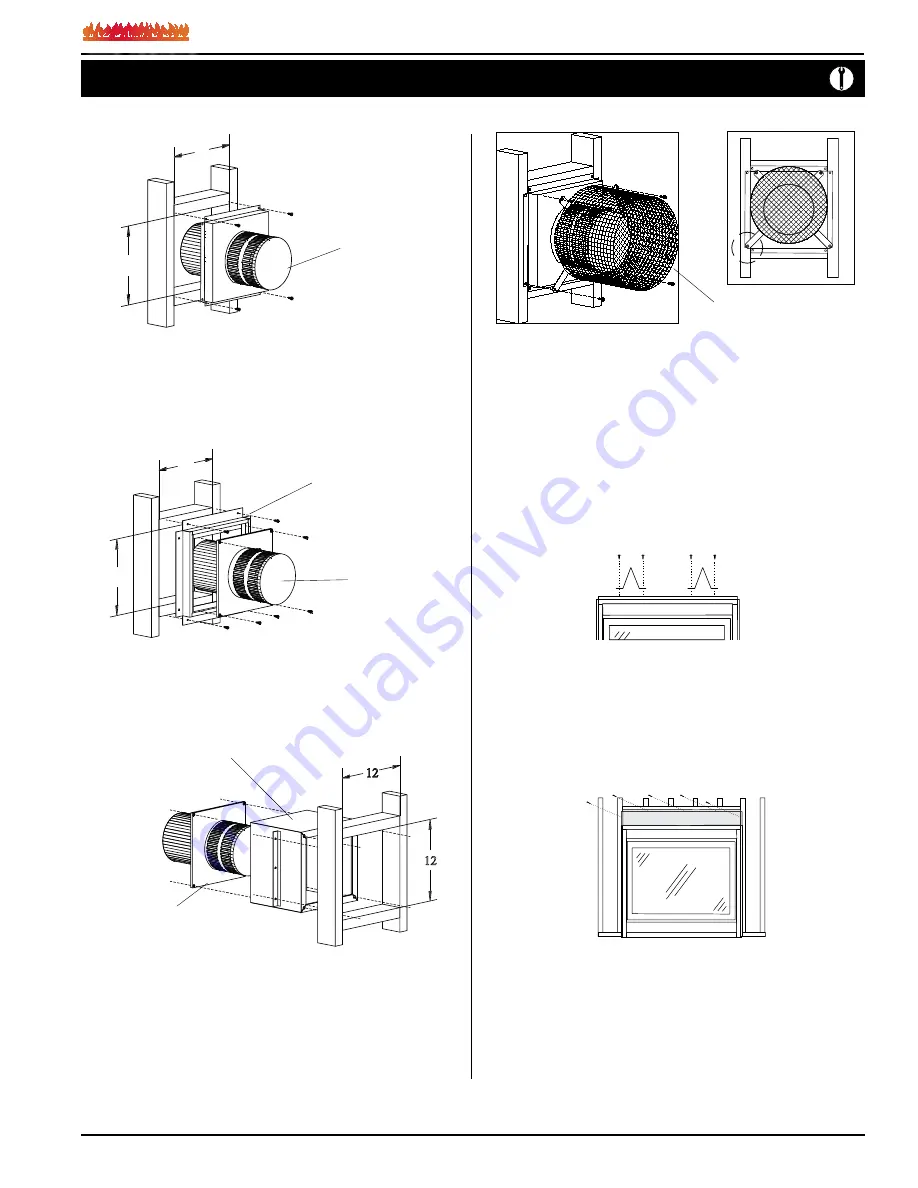

Installing the Nailing

Flange Extension

Once the fireplace is placed into the framed opening, the supplied

nailing extension must be placed along the top edge of the fireplace,

and nailed in place to the framing, as illustrated below.

Figure 6c.

Installing the Nailing Flange Extension.