Page 18

L38DF* Indoor Gas Fireplace

XG0180 - 053111

Installation

Section 6: Finishing

WARNING!

We recommend careful consideration be given to the effects of elevated

mantel temperatures which may be in excess of product design,

for example: candles, plastic or pictures. This can cause melting,

deformation, discolouration or premature failure of T.V. radio, and other

electronic components.

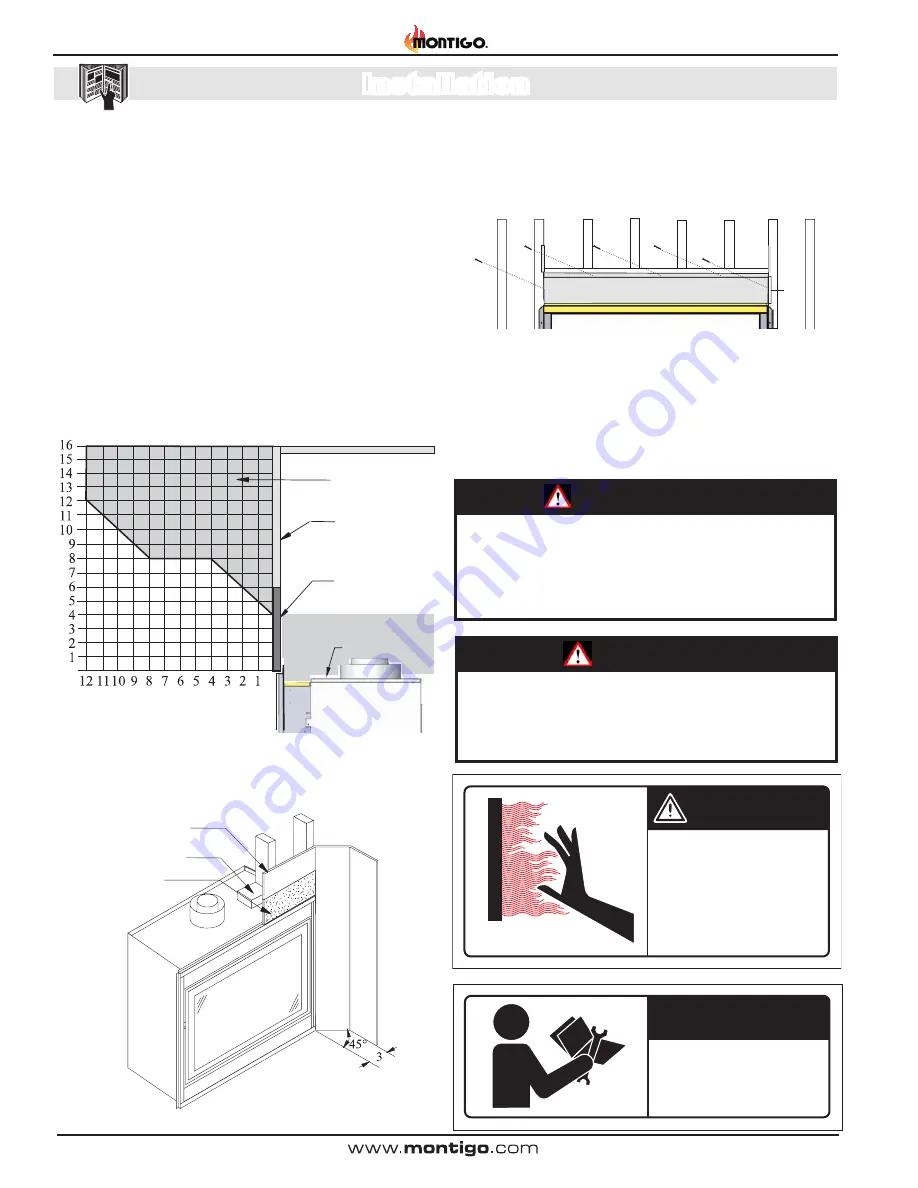

Figure 23.

Combustible mantels and facings.

WARNING!

When covering the upper metal portion of the fireplace, up to 4" (

as

shown,

Fig.24

) with a non-combustible material

Please Note

: The

decorative facing materials may be subject to temperatures in excess

of 250° F. This should be considered when selecting facing materials.

Finishing Around the Fireplace

Combustible mantels and mouldings may be safely installed over the

top and on the front of the fireplace provided that they do not project

beyond shaded area shown in Figure 23.

Fireplace Facing

When sizing the finish material for your fireplace, it is important to

remember the following: THE OPENING MUST NOT BE OBSTRUCTED

IN ANY WAY - to do so restricts the air supply for the control compartments

and heat exchanger it also prevents access for servicing controls.

The face of the fireplace may be painted to match the room decor,

provided you use a heat-resistant paint. Decorative facing must not

extend past the fireplace opening at all, because it will interfere with

the access to retainers for removal of glass door.

Figure 25.

Installing the Nailing Flange Extension.

Installing the Nailing Flange Extension

Once the fireplace is placed into the rough framed opening, and the

supplied steel lintel is in place, (Part No. H38074) (see

Figure 2

),

The supplied nailing extension must be placed along the top edge of

the fireplace and securely fastened in place to the metal lintel, and

combustible wood framing. Note: The nailing flange extension can be

substituted with a piece of NON-Combustible material of the same size

and thermal characteristics, ie: cement board or equivalent.

XW2004

Glass doors on gas fireplaces are

extremely hot while the fireplace is

on and remain hot even after the

fireplace has been turned off. Safety

screens are available and can reduce

the risks of severe burns. Please

keep children away from the fireplace

at all times.

CAUTION

Do not use ammonia based or abrasive

cleaners on the glass, they will

permanently etch the surface. Use an

approved gas fireplace glass cleaner

such as Kel-Kem or White off.

NOTICE

XW2000

6"

Non-Combustible

Facing Material

Header

Drywall/

Sheetrock

Combustible

Facing Material

Header

Drywall/

Sheetrock

3”

Figure 24.

Combustible surrounds.

Side wall clearances are 3". Combustible surrounds may be installed

with 3" clearance to the side of the fireplace as shown in

Figure 24

.

Top of fireplace

Non-Combustible

Combustible Facing

Material

Facing Material

Combustible

Construction allowed

in shaded area

Steel Stud construction allowable

within the grey-out area

Horizontal Run (in.)

Vertical Height (in.)