Page 13

L52DF* Indoor Gas Fireplace

XG0185 - 100511.1

Installation

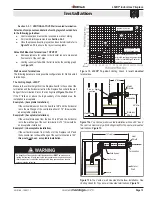

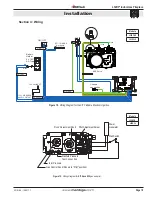

The Venting graph: L52DF*

Measure the vertical height from the fireplace hearth to the centre of the

termination and the horizontal run from the fireplace flue collar to the wall

flange of the termination. Plot on the Venting Graph

Figure 13

with an 'X'.

If the 'X' falls on or above the top boundary of the shaded area, the

installation is acceptable.

Example A: (Acceptable Installation)

If the vertical dimension from the hearth is 108" and the horizontal

run to the wall flange of the vent termination is 174", this would be

an acceptable installation.

Example B: (Acceptable Installation)

If the vertical dimension from the hearth is 60" and the horizontal

run to the wall flange of the vent termination is 72", this would be

an acceptable installation.

Example C: (Unacceptable Installation)

If the vertical dimension from the floor of the fireplace is 60" and

the horizontal run to the wall flange of the vent termination is 144",

this would not be an acceptable installation.

Figure 13.

L52DF* Top Vent

Venting Graph for

wall mounted

terminations.

Figure 13a.

T

op Vented, wall mounted installation with one 90° bend.

The vent run must comply with Venting Graph for Top vent, wall mounted

terminations,

Figure 13.

Figure 13b.

Top Vented, wall mounted Multi-elbow installation. See

Venting Graph for Top vent, wall mounted terminations,

Figure 12

.

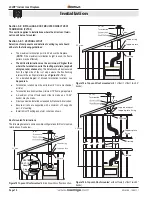

Section 3-3-1: VEnTIng LAYOUT: Wall mounted termination.

Selection of components and details of venting layout should adhere

to the following guidelines:

Vent terminations must not be recessed in walls or siding.

For Heat Shield requirements see

Section 3-3-3

.

Once the proposed venting layout has been determined refer to

Figure 13 or 15

to ensure the layout is acceptable.

notes Wall Mounted Terminations:

TOP VEnT

All measurements for vertical or horizontal runs are measured

from center of the vent pipe.

Venting runs

must

fall within the limits set by the venting graph,

see

Figure 13

.

Wall mounted Terminations

The following details are some possible configurations for Wall mounted

terminations.

Solid Section

Flex Section

Hearth

15’foot Max.

Heat

Shield

Termination

Exterior

Wall

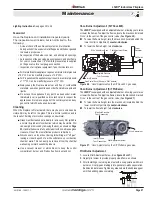

An inspection of the explosion relief flappers and door

MUST

be made prior to

lighting the fireplace. A faulty seal on the door gasket and/or explosion ports will

result in products of combustion leaking into the living space and may result in

carbon monoxide poisoning.

WARnIng

A

C

B

36”

36

40

”

If your installation does not fall

within the venting graph parameters

contact a local Montigo Dealer for

Power Venting options.

Unacceptable vent run

within shaded area.

Acceptable vent run

within non-shaded area.

Heat

Shield

Termination

Hearth

Exterior

Wall

40"Min.

36" Max.

Flex or Rigid

section