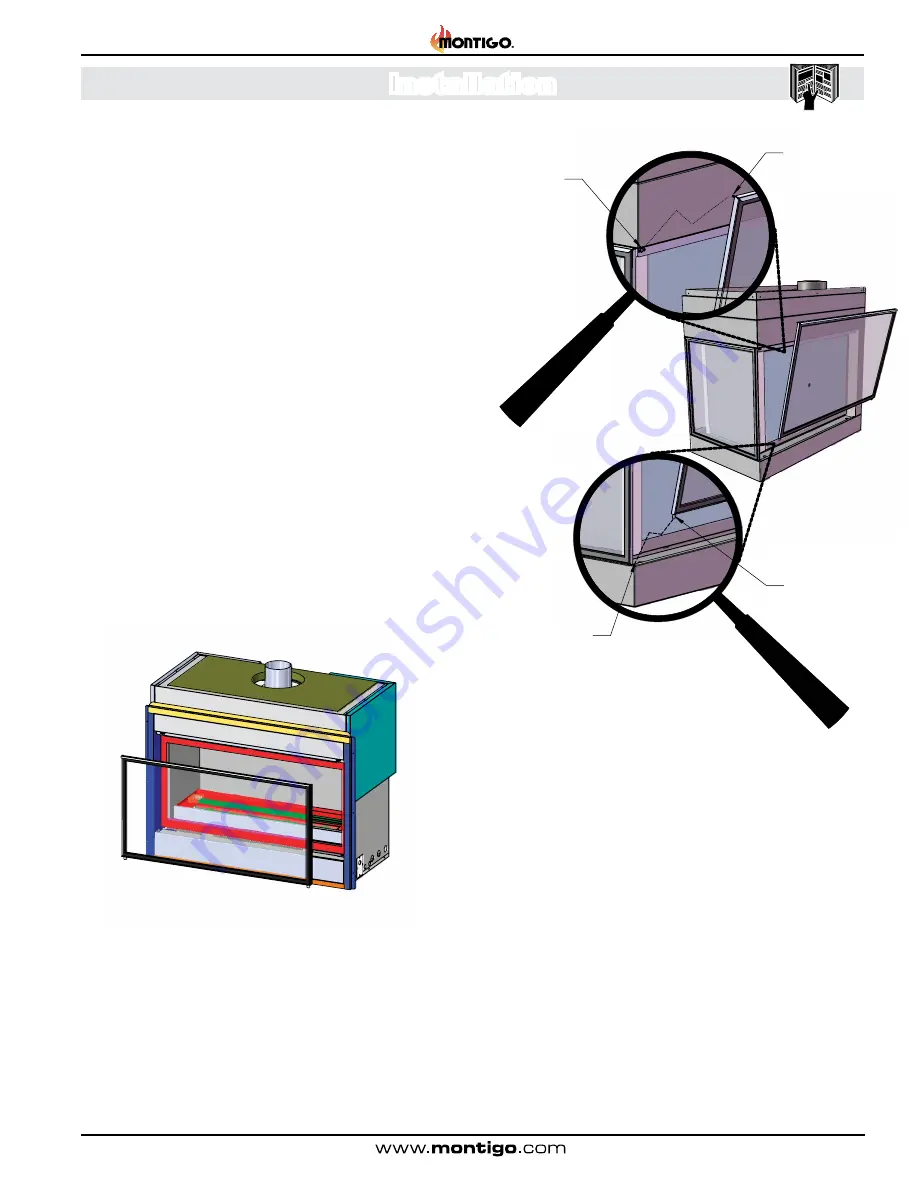

Section 6: Screen Installation and Removal

Screen Bottom

Tabs

Screen Tab

Receptacles

Upper Screen

Studs

Upper Screen

Stud Catch

Left Side Detail

Left Side Detail

Removing / Attaching

The Safety Screens

To Remove the screen(s)

Simply grasp each top

outer corner of the screen

with your thumb and

finger and pull towards

you. Once the upper

Screen Studs are free, at

an angle, lift the screen

from the lower slots in

which the Screen Bottom

Tabs are held. Place the

screen in a safe place.

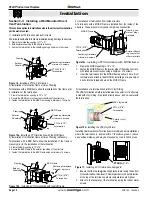

To Install the Screen(s).

Holding the screens at an

angle away from the

fireplace, locate the

Screen Bottom Tabs at the

lower corners of the

screen into the Screen

Tab Recepticles in the

lower section of the

fireplace. Make sure the

tabs and screens are

lowered all the way down

into the Screen Tab

Recepticles on the

fireplace. Then push each

Upper Screen Stud at the

top corners of the screen

into the Upper Screen

Stud Catchs in the

fireplace.

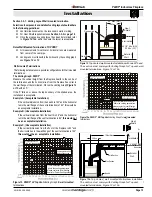

Removing / Attaching Screens:

To Remove Screens:

Grasp each top outer corner of the screen with your thumb and

finger and pull towards yourself. When the upper Screen Studs are

free, lift the screen at an angle from the lower slots from which the

Screen Bottom Tabs are held. Place the screen in a safe place.

To Install Screens:

Hold the screens at an angle away from the fireplace, and locate

the Screen Bottom Tabs at the lower corners of the screen. Place

the screen into the Screen Tab Receptacles in the lower section

of the fireplace.

Make sure the tabs and screens are lowered all the way down

into the Screen Tab Receptacles on the fireplace. Then, push

each Upper Screen Stud on the top corners of the screen into

the Upper Screen Stud Receptacles in the fireplace.

Figure 22b.

Screen Installation and Removal

Figure 22a.

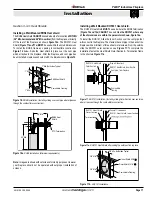

Screen Door Numbers (Replacement Parts)

Replacement Screens:

For replacement part order numbers, please refer to section

"

Replacement Parts:

" on page 30.

Note:

Do not operate fireplace without all screens in place.

Page 21

P42DF* Indoor Gas Fireplace

XG0195 -150204.2

Installation