Page 22

P52DF* Indoor Gas Fireplace

XG0196 - 150204.3

Installation

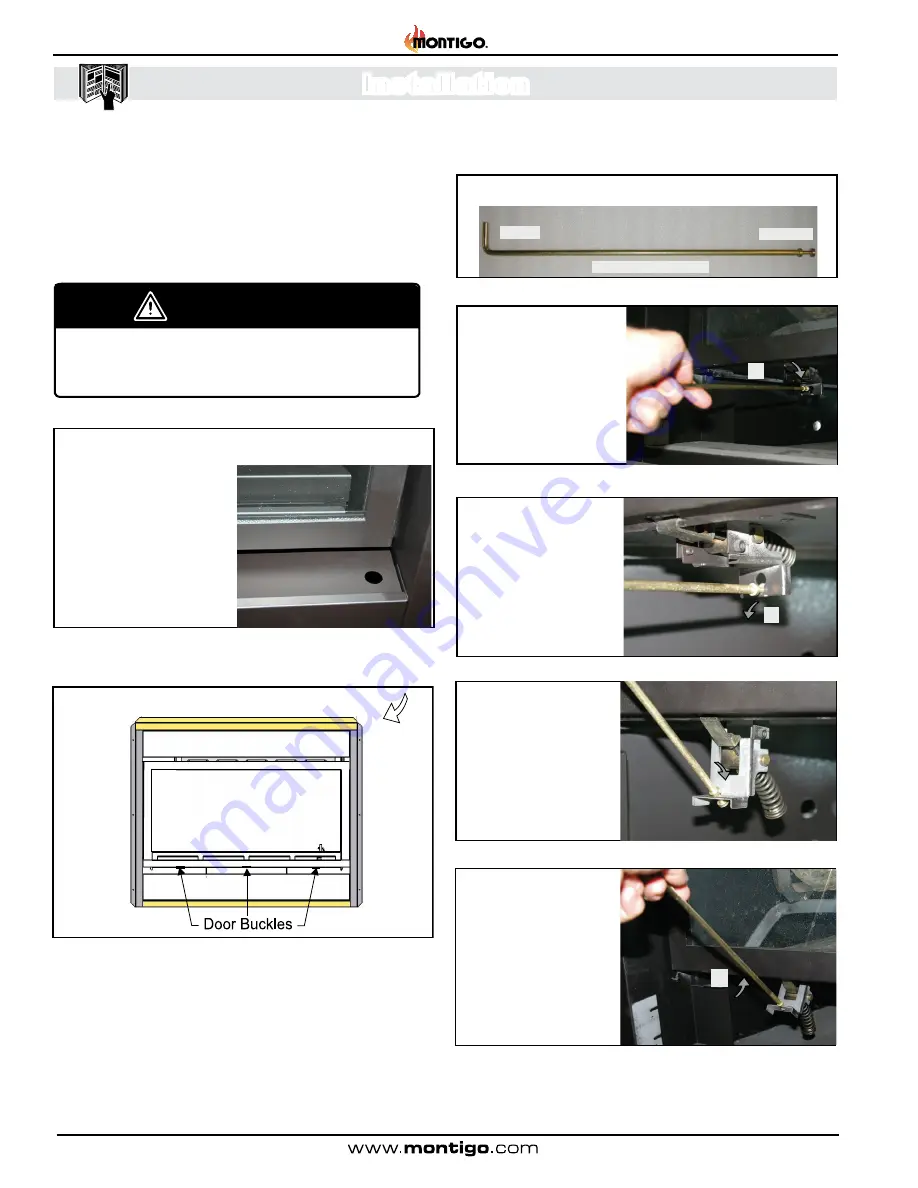

Section 8: Installing & Removing the Door

Removing the door:

The

P52DF*

doors are removed in a few simple steps.

Follow these below to remove the Horizontal access panel,

unlatch the door buckles and, remove the door. Replace

in reverse order.

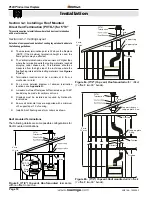

Remove the Horizontal Access Panel:

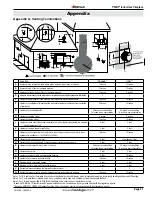

Figure 22a.

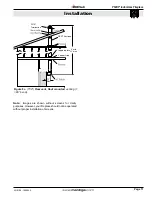

Locate the door buckles.

Door Latch Hook

Door Latch Slot

Hand-hold

Release the Door Buckles

Figure 22.

Removing and installing the Horizontal .......

Access Panel

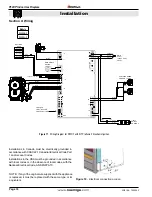

Figure 22b.

Door buckle Tool

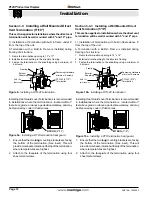

1

Step 4:

Firmly grasp hand-

hold end of Door

buckle tool and place

the machined end in

the slot under door

frame. (as shown)

Figure 22c.

Step 3:

Step 1:

Remove the Horizontal

cover by placing fingers

in both finger holes, then

pushing away from you

and lifting out. Place it

aside during maintenance

or cleaning.

Install in reverse order.

Remove the Horizontal Access Panel:

2

Step 5:

Ensure the tool is firmly

in the lower end of

the slot, (as shown),

Then pull toward you

(Caution: hold the tool

securely).

3

Step 6:

Pull hard if necessary

to release the spring

tension. (Caution: The

latch springs back with

force, hold the tool

securely).

4

Step 7:

Remove the tool from

the latch slot. Ensure

the latches are hanging

freely, the hook end

is released from the

bottom of the door.

(Repeat all 4-steps for

the remaining latches).

Figure 22d.

Figure 22e.

Figure 22f.

Locate the Door Buckles:

Step 2:

Finger Holes

Installed Gas

Valve Cover

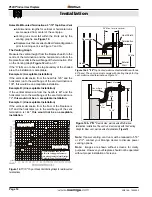

WARNING

When reinstalling door(s), always make sure all door

buckles are properly hooked and fully engaged.