Moog ACV with CANopen bus interface

2 Access over CANopen

CAN bit rate and Node-ID configuration

B99224-DV018-D-211, Rev. A, October 2018

14

2.7.1 CAN bit rate and Node-ID configuration using LSS services

The digital servo valve has a Layer Setting Service (LSS) slave implementation according to CiA 305. With

this service the bit rate and the Node-ID of the digital servo valve can be configured by a LSS master.

The Layer Setting Services (LSS) use the COB-IDs 0x7E4 and 0x7E5.

The LSS service provides two methods to change the bit rate of the servo valve:

1.

If a point to point connection has been established between the LSS master and the servo valve, the bit

rate and the Node-ID is set in dialog mode.

2.

If more than one slave nodes are connected to the network at the same time, the bit rate and Node-ID

can be changed with the LSS service by selecting this particular slave device by his unique identification

object (0x1018). This node identification object is worldwide unique and will be programmed during pro-

duction. Information about the identification object address is available from the name plate of the device

or can be inquired by using SDO or the boot-up message.

The LSS service itself stores the new settings permanently in the servo valve. It is not necessary to initiate a

manual Store command as needed for other configuration parameters of the servo valve.

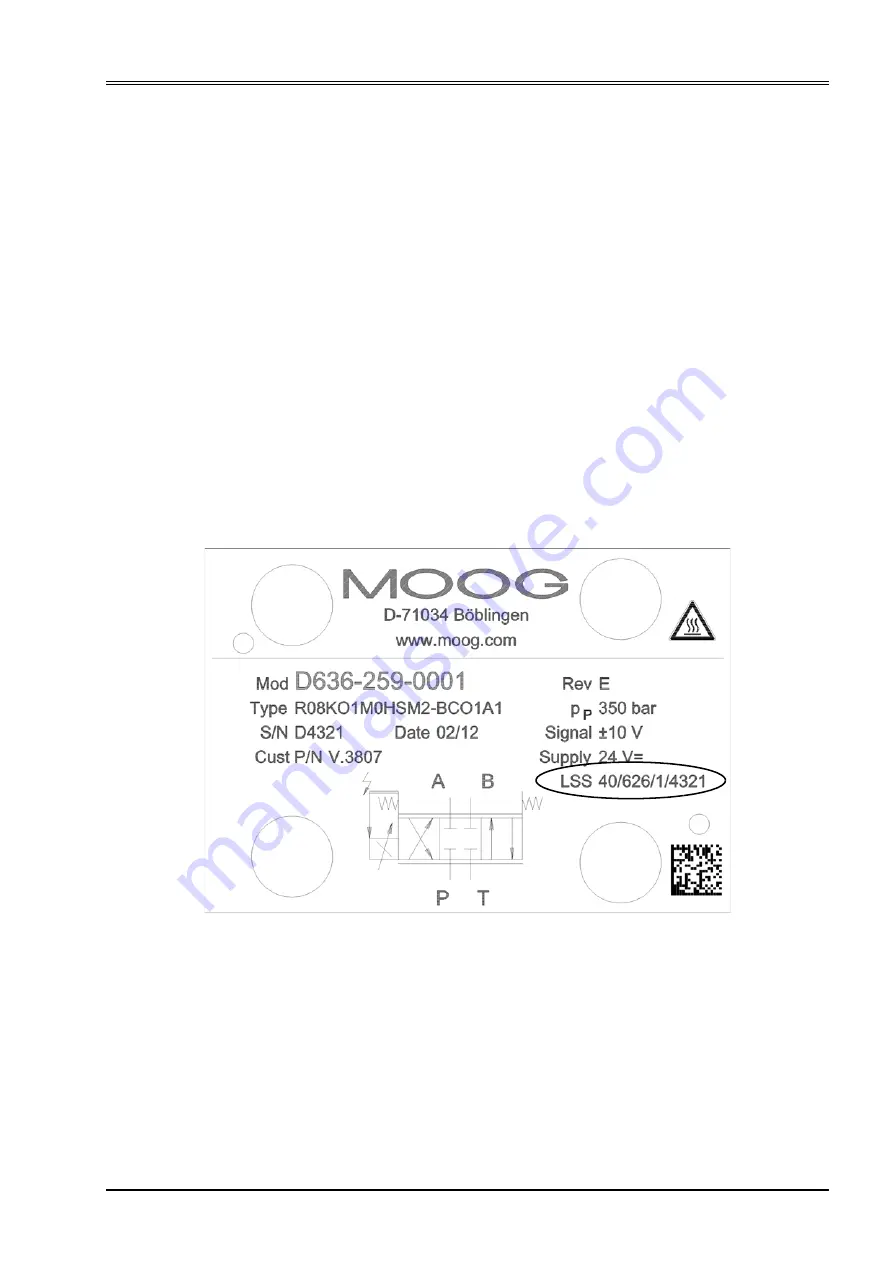

The identification object (Vendor-ID, Product Code, Revision Number, Serial Number) is printed on the name

plate of the servo valve.

For more details about the LSS service see CiA 305.

Chapter "4.1.5 Object 0x1018: Identity object", page 40

Figure 5: Name plate of the device with identification object address

2.7.2 CAN bit rate and Node-ID configuration using SDO protocol

In case a network master does not support the LSS services, the bit rate and the Node-ID in the servo valve

can be configured by the SDO protocol. Therefore two SDO objects were introduced.

When changing these settings, they will get active not before either a power-up or a NMT-reset communica-

tion are initiated. That makes sure that the CAN communication will not get interrupted by changing these ba-

sic settings.

Different to all other configuration parameters, writing these parameters to the servo valve, stores them per-

manently. It is not necessary to initiate a manual Store command as needed for all other configuration param-

eters of the servo valve.