903-0628-00 Rev. 1

Model 903-HD User's Guide – FMB-X-2.5

Focal Technologies Corp.

Page 7-4

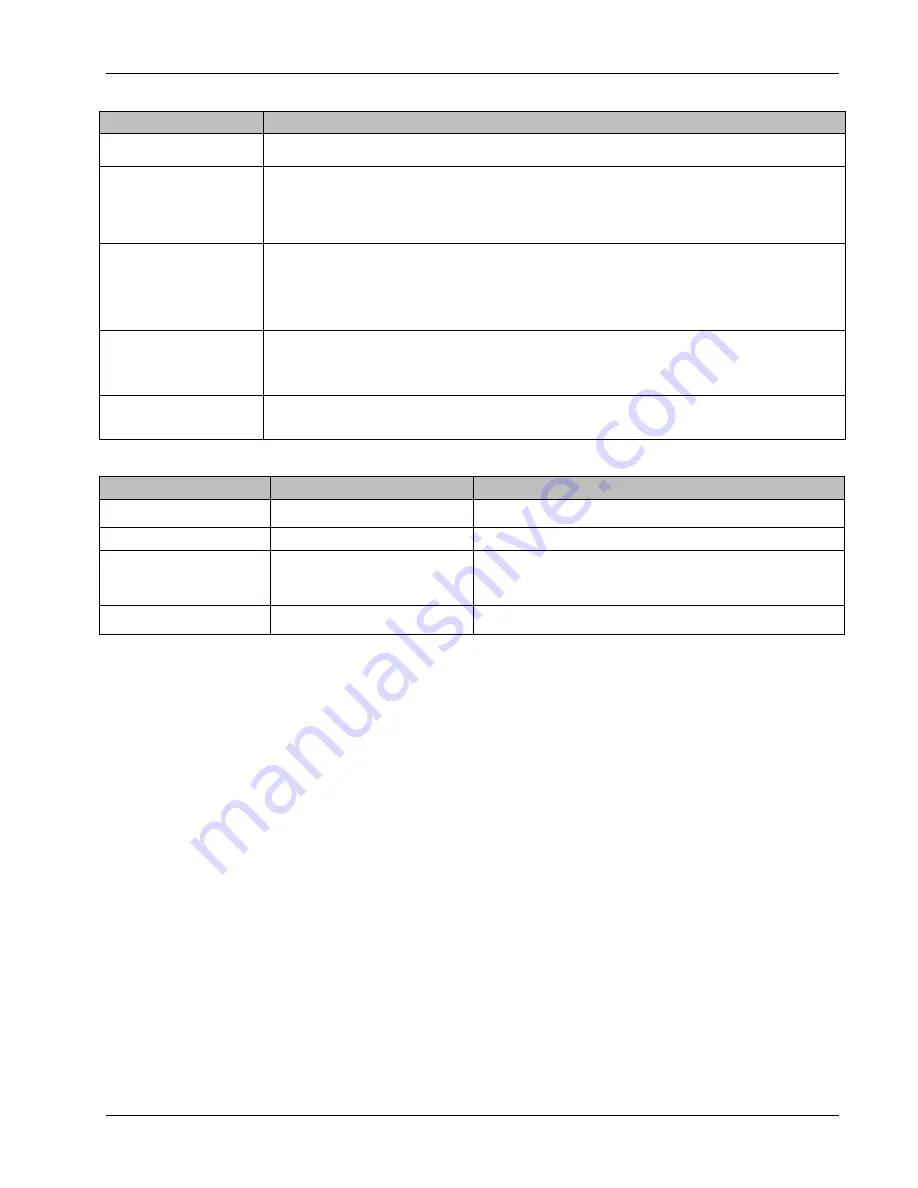

7.3.1.1 Card Diagnostic LEDs:

CARD

LED STATUS – NORMAL OPERATION CONDITION

Fiber Multiplexer Boards

Green LED on LINK, FO-RX and STAT on both remote and console modules.

Ethernet Cards

(EIB-10/100)

Green RJ-45 port LED: ON = valid link, FLASHING = data activity

Yellow RJ-45 port LED: ON = full duplex link, FLASHING = data collisions

Green Panel LED (“T”): ON = data received from backplane (10 Mbps EIB only)

Red Panel LED (“R”): ON = data sent to backplane (10 Mbps EIB only)

AIB-4, DIB-232, DIB-485

Cards

Two LEDs for each channel indicate the presence of a signal transmitted or received:

Green LED (“T”): ON = data being transmitted out of card front panel to external equipment.

Red LED (“R”): ON = data being received into card front panel from external equipment.

Non-digital i/o cards (e.g. AIB-MS900) or blank sockets force both LEDs on.

Remote Module Data I/O

(903-High Density Only)

Two LEDs for each channel indicate the presence of a signal transmitted or received:

Green LED ("T”): ON = data being transmitted out of i/o box to external equipment.

Red LED (“R”): ON = data being received into i/o box from external equipment.

Power Supply

Green LEDs on PSU front panel indicate corresponding output voltage levels are OK.

Flickering or dim LEDs indicates power problems on the rails.

7.3.1.2 FMB-X-2.5 Link LEDs (FMB Front Panel):

LED STATUS

CONDITION

POTENTIAL SOLUTION

Both LEDs On Green

Normal operating condition

(Valid uplink/downlink established)

OK

LED Flickering Green/Red

Insufficient power budget

Verify optical power budget with VOAT.

One LED On Green &

One LED On Red

Insufficient optical power in one

direction

Verify attenuation, optical cable and connections.

Re-establish synchronization (unplug/plug the fiber optic cable).

Replace FMB that has the red LED if received optical power is OK.

Check FMB DIP switch settings per Manual.

Both LEDs Red

Problem with optics between

remote and console modules

Bad connector: clean all optical connections.

Bad fiber: bypass fiber sections with jumpers.

7.4 General Handling and Failure Reporting Guidelines

Verify the problem on other cards or channels, if possible.

Use a spare card and see if that fixes the problem.

Note card part number and serial number, as well as PO number, if possible.

Confirm whether the problem appeared during installation or well after successful installation, i.e. did

the problem occur with no changes to a previously working system?

Log a diagnostics file, if relevant, and email it to the factory. Diagnostics files include all optical

measurements, temperature, voltage levels, video syncs, and errors detected. Ensure the log file is

configured properly per the software user’s manual. (The various log fields may be enabled/disabled

and the logging frequency may be changed from the one second default.)

7.4.1 Focal Service and Support

It is recommended that damaged cards or cards/systems that the fault cannot be found in using the above

guide be returned to Focal or local supplier.

Request a RMA # from Focal (Tel: 1-902-468-2263) and complete a return product form.

Provide key information, such as a description of the problem, the part number of the board, how long

the board has been in service, any attempted fixes, and the urgency for repair.

Ensure packaging is secure and ESD safe.

Summary of Contents for Focal 903

Page 78: ...903 0628 00 Rev 1 Model 903 HD User s Guide FMB X 2 5 This page intentionally left blank ...

Page 79: ...903 0628 00 Rev 1 Model 903 HD User s Guide FMB X 2 5 APPENDICES ...

Page 80: ...903 0628 00 Rev 1 Model 903 HD User s Guide FMB X 2 5 This page intentionally left blank ...

Page 86: ...903 0628 00 Rev 1 Model 903 HD User s Guide FMB X 2 5 This page intentionally left blank ...

Page 89: ...903 0628 00 Rev 1 Model 903 HD User s Guide FMB X 2 5 APPENDIX E BACKPLANE PIN CONFIGURATIONS ...