6

STRAC2 Hardware Manual

920-0118 Rev B

03/26/21

3.1 Connecting to Power

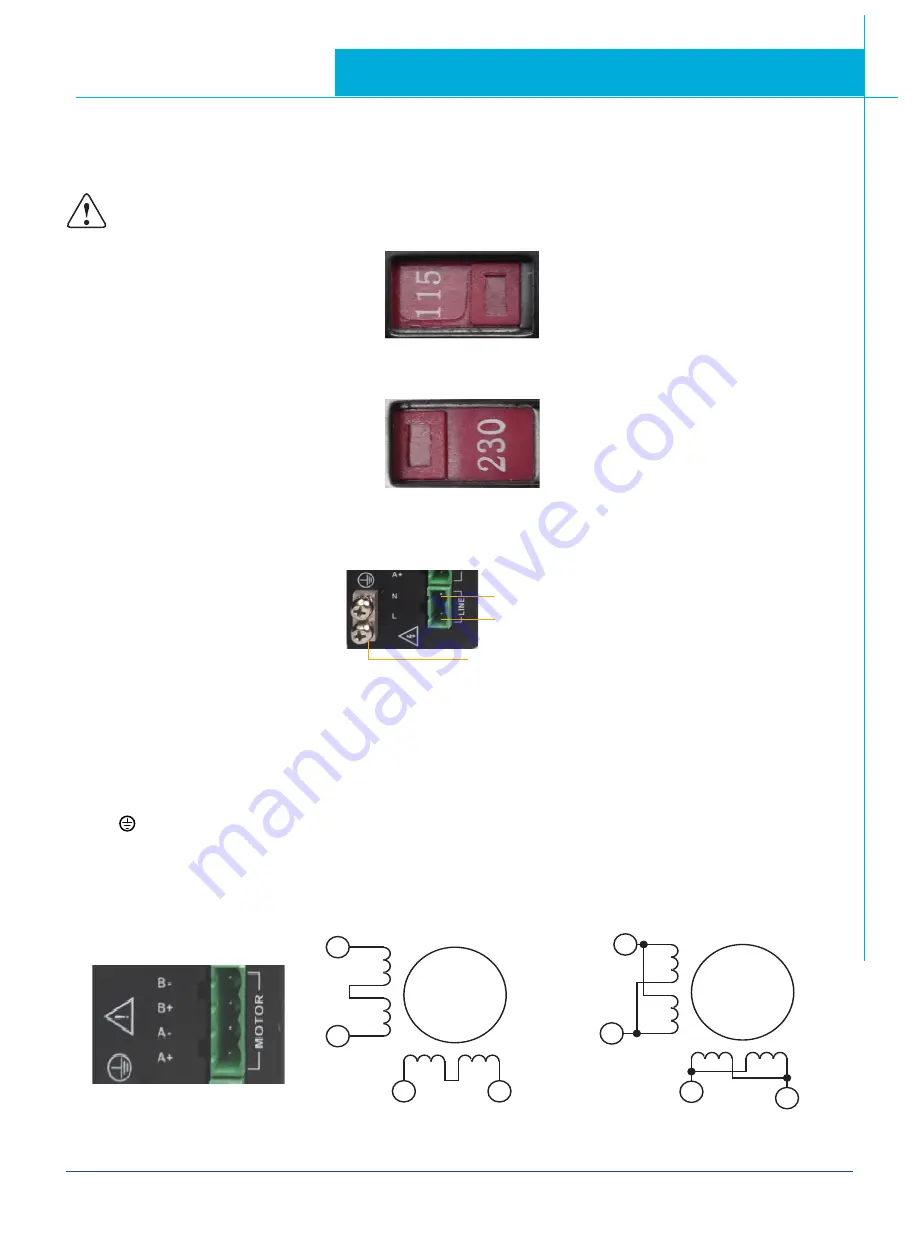

Use the supplied connector to connect to the AC supply according to the diagram below. Use 16 AWG wire for Line (L) and Neutral (N).

Use 14 AWG for Earth Ground (G).

AC input voltage must be

selected by switch.Check

input voltage avoiding damage

before power on!

Input Voltage between 90Vac to 135Vac: Set the switch on 115V Status

Input Voltage between 135VAC to 240VAC: Set the switch on 230V Status

The STRAC2 contains an internal 5A fast acting fuse.

Earth Ground (green)

Neutral (white)

Line-hot (black)

Care should always be taken when working with high voltages.

3.2 Connecting to a Motor

Motor connections should be made according to the following diagrams.

Never connect or disconnect the motor while the power is on.

Note: it is highly recommended that you use a motor with a shielded cable with the STRAC2. Always connect the cable drain wire to the

drive’s terminal (next to the A+ terminal)

The recommended Applied Motion motors for the STRAC2 include shielded cables. See the Recommended Motors section for a list of

part numbers.

Be sure to connect the cable shield for safety and to minimize electrical interference.

A+

A–

B+

B–

8

lead

motor

8 Leads Series Connected

8 Leads Parallel Connected

8

lead

motor

White

Orange

Brown

Green

Red

Yellow

Blue

Black

White

Brown

Orange

Green

Red

Blue

Yellow

Black

B+

A+

A–

B–