27

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

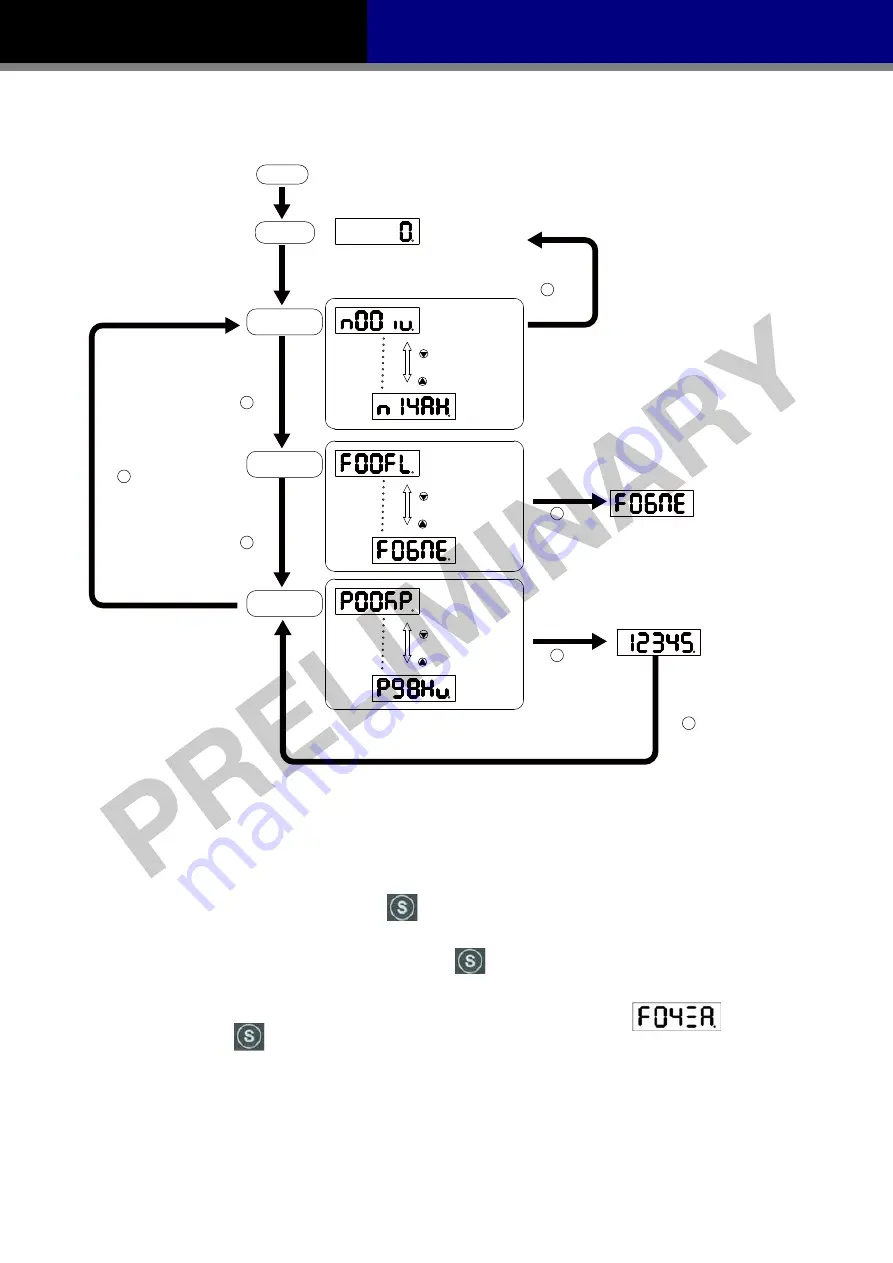

5.3 Key Operation Flowchart

Monitor Status

Power On

In factory default mode, it will display motor’s rotatory velocity.(*NOTE 1)

The last dot shows whether the drive is enable or disable.

Monitor Parameters

Press the UP and

DOWN key to scroll

through and change

monitor status

S

Press SET key back

to Monitor Status

Press any key

Function Parameters

M

Press and hold the

MODE key for 1 second

Press the UP and

DOWN key to scroll

through and change

function selection

S

Press and hold SET key to

confirm selection and execute it.

Drive Parameters

Configuration

M

Press and hold the MODE

key for 1 second(*NOTE 4)

Press the UP and

DOWN key to scroll

through and change

parameter selection.

S

Press SET key enter

to value setting mode

Press and hold for 1 second

the SET key to confirm setting value

*Note(3)

S

M

Press and hold the

MODE key for 1 second

Press SET key back to

Drive Parameters Configuration

mode without changing.

*NOTE(2)

*NOTE:

1) When power is applied, drive

’

s display will show customer de

fi

ned monitoring mode. In factory

default mode, it will display motor

’

s rotatory velocity.

2) In parameter setting mode, press set

key will quit from parameter setting mode, and return

back to parameter selection mode, and changes will not be saved.

3) In parameter setting mode, press and hold set

button will con

fi

rm and save current

parameter setting. This will effect immediately, however, this change will not save to drive

’

s Flash.

If parameter is required for permanent use, please go to function mode

“

”

, and then

press and hold set

button to save the parameter change.