The Interface Solution Experts 17

SPA

2

Programmable Current/Voltage

Limit Alarm Trips

D

D

D

U

U

APPLY

ZERO

APPLY

FULL

EXIT

APPLY

APPLY

INPUT

SEL

U

TRIM INPUT menu

SEL

XXXXX

EGU

U

D

XXXXX

EGU

U

D

SEL

SEL

SEL

SEL

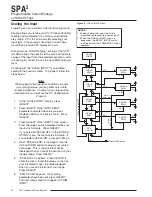

Applying Input (Bench Scaling)

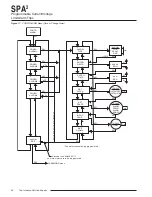

Figure 9 gives an overview of the Apply Input menu.

With Bench Scaling, also called “Standard Ranging”,

inputs are “captured” at their zero and full scale levels

using external, calibrated equipment.

1.

At the “APPLY INPUT” screen, press

SELECT.

2.

“APPLY ZERO” appears. Apply the input you

wish as your zero and press

SELECT. Wait

until it is flashed on the display and press

SELECT to capture.

3.

Next, “APPLY FULL” is displayed. Apply the

value of your full range and press

SELECT.

When this is flashed, press

SELECT to

capture.

4.

Press

SELECT at “EXIT APPLY” and exit the

menu.

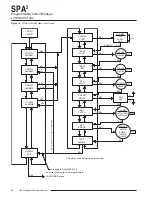

Input Trimming

Figure 10 gives an overview of the Input Trimming

menu.

Input trimming increases the measurement accuracy

of the parameter you are trimming by matching the

reading of its actual input to its scaling. The SPA

2

offers the use of a factory-configured trimming feature

(“FCTRY TRIM“) or user-set, one-point or two-point

(“USER 1PNT” OR “USER 2PNT”) trimming.

Unit default is “FCTRY TRIM”. If another trimming

selection had been made and you wish to return to the

“FCTRY TRIM” feature, follow the instructions below.

1.

Press

SELECT at the “TRIM INPUT” SCREEN.

Once the “TRIM MODE” appears, press

SELECT.

2.

“FCTRY TRIM” is displayed, press

SELECT.

This takes you to the “EXIT TRIM” screen.

3.

To exit, press

SELECT.

To input user-specific trim values, perform the

following steps:

1.

At the “TRIM INPUT” display, press

SELECT.

When “TRIM MODE” appears, press

SELECT

again. Use the

UP and DOWN buttons to reach

the user-set trimming menus. Press

SELECT

once the desired parameter is displayed–

“USER 1PNT” or “USER 2PNT”.

2.

“TRIM ZERO” appears. To program, press

SELECT. Your present zero scaling value is

shown and prompts you to “APPLY” your value.

Press

SELECT, once your value is present and

flashing at the appropriate input terminals,

press

SELECT again. If you selected “USER

1PNT” trimming, “EXIT TRIM” appears. Press

SELECT to reach the “CONFG AOUT” menu (or

“CONFG ALARM” menu if the -AO option is not

enabled). Proceed to Step 3 for “USER 2PNT”

trimming.

3.

If you selected “USER 2PNT” trimming, repeat

the instructions in Step 2 for the “TRIM FULL”

setting. Press

SELECT when “EXIT TRIM” is

displayed to reach the “CONFG AOUT” menu

(or “CONFG ALARM” menu if the -AO option is

not enabled).

Note:

Trim only the zero and full values entered in the

“SCALE INPUT” menu through the front panel

pushbuttons. To trim values other than those

specified in the “SCALE INPUT” menu, you must

use the PC Configuration Software program.

Figure 9.

APPLY INPUT Menu