RIY

The Interface Solution Experts 5

-6

-5

-4

-3

-2

-1

ON

OFF

1 2

3

6

7

9

5

0

AB

D

E F

4

8

C

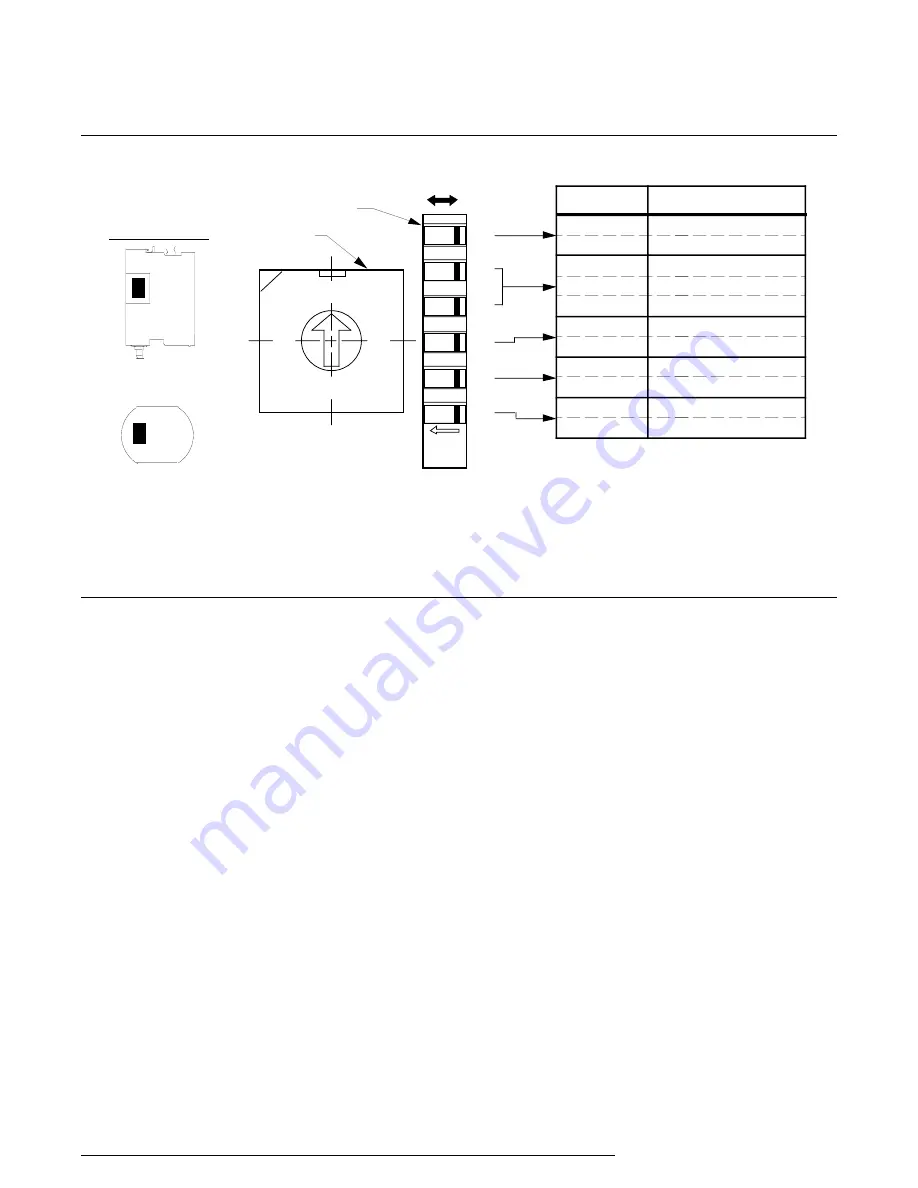

SW 302

SW 301

ON

OFF

-2 OFF/-3 OFF

-2 OFF/-3 ON

-2 ON/-3 ANY

ON

OFF

ON

OFF

ON

OFF

DISPLAYS CELSIUS

DISPLAYS FAHRENHEIT

2-WIRE, DUAL 2-WIRE

3-WIRE, DUAL 3-WIRE

4-WIRE, TRIPLE 2-WIRE

DOWNSCALE DRIVE

UPSCALE DRIVE

QUICK RANGING

STANDARD RANGING

KEYBOARD LOCKOUT

KEYBOARD ENABLE

SETTINGS

FEATURES

ORIENTATION

HP

DIN

NOTES:

1. Refer to table 2 for SW302 switch setting uses.

2. The relative position of SW301 and SW302 is identical for HP- and DIN-style units.

3. SW301-6 may be inactive in earlier units. In these units, the switch setting can be disregarded.

Figure 2.

Internal Switches, Layout, Designations, and Settings

Switches for DIN-style units are accessed by remov-

ing a small, L-shaped panel from the upper right-side

of the unit. This panel is bent over the top, right-side

edge of the unit and is secured with a single screw on

top. A Phillips-head screwdriver is required to

remove one screw securing the small L-shaped panel

to the housing frame.

The configuration switches are used to set the

following features:

SW301-1

— Displayed Temperature Type

ON – Sensor input displayed in Celsius

OFF – Sensor input displayed in Fahrenheit

This switch determines the type of temperature

units that will be displayed on the LCD. If an

ohms range is selected, the display will show

OHMS and this switch is ignored.

SW301-2 & -3

— Number of Wires or Sensors

These two switches determine the number of

wires for a single sensor input, or the number of

sensors of a multi-sensor input configuration.

Refer to table 2.

SW301-4

— Upscale/Downscale on Fault

ON – Downscale Output Drive on Fault

OFF – Upscale Output Drive on Fault

This switch determines the reaction of the RIY

output when an error is detected (during power-

on diagnostics) or when an input or sensor lead is

physically open.

SW301-5

— Ranging Method

ON – Quick Ranging (for units with LCD’s only)

OFF – Standard Ranging

Quick Ranging can only be performed on units

with an LCD. To set the 4-20 mA output with this

ranging method, dc power is the only input

needed for the unit. The pushbuttons are used to

set the zero and full-scale inputs.

Standard Ranging requires an input source, an

output monitoring device, and dc power. The

push buttons are used to capture the zero and

full-scale input values and to trim the zero- and

100-percent output settings.