Maintenance

A : Wear Check

e)

These checks should be regularly repeated, especially when the seed drill has been used on hard

or stony soil.

Checks

Wear check

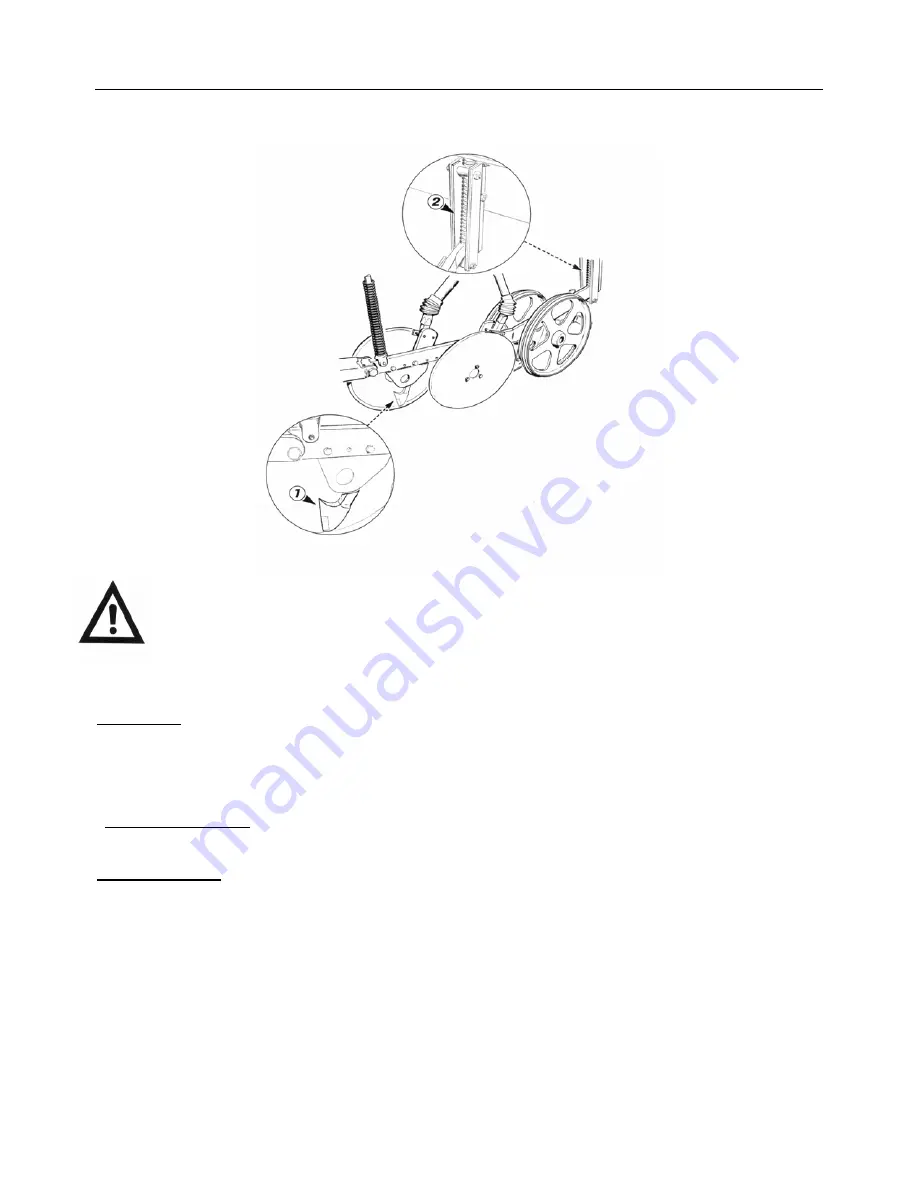

- of coulters (1)

Coulters are the essential furrowing part and must retain aggressive shape. Coulters can be rebuilt with

suitable welding rods before wear becomes too pronounced.

- of seed drill arm rear guides (2)

NEVER LUBRICATE.

- turn or replace the plates as soon as their thickness is significantly reduced.

Tightening check

- After 10 hours of operation:

Check the tightening of the furrowing system screws: disc securing screws and check tapered roller

bearings.

If those taper roller bearings have play, they should be tightened:

- Remove the dust cover

-

Tighten the ¾” UNF Flange nut with a torque wrench,

do not exceed 120N/m

-

After 20 hours of operation : Check the tightening of the main nuts.

-

Periodically check wheel rim tightening and tyre pressure:

Tyres – 10.5 x 15 (240G) : 2 bar

- 19.0/45-17 (300G) : 1.5 bar

28

Summary of Contents for 240G

Page 9: ...Safety Instruction Decals Safety Stickers 9 ...

Page 10: ...Safety Instruction Decals 10 ...

Page 11: ...Safety Instruction Decals 11 25 ...

Page 12: ......

Page 22: ...Settings A Distribution Settings Size metres 2 40 3 00 Turns 62 5 50 22 ...

Page 37: ...Flow Rate Tables Calibration Procedure 37 ...

Page 38: ...Flow Rate Tables Calibration Procedure 38 ...

Page 39: ...Flow Rate Tables Calibration Procedure 39 ...

Page 40: ...Flow Rate Tables Calibration Procedure 40 ...

Page 43: ...Grassland Parts booklet 2007 grassland seeding line ...

Page 45: ...Grassland Main Chassis ...